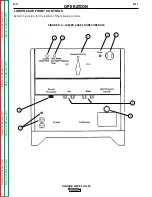

1.

POWER ON/OFF — A momentary start/stop

pushbutton, which controls the input contactor. If

the input power supply goes off or if the thermo-

stat in the welder trips, the start pushbutton must

be pressed to restart the welder.

2.

PILOT LIGHT — Indicates when the input contac-

tor is energized (power is on).

Do not switch polarity under load.

3.

POLARITY SWITCH — Selects DC-/AC/DC+

4.

FUSE F1 — 0.5 amp control circuit fuse protects

the control transformer from overloads. Input

overvoltage protection circuitry will blow this fuse

to protect electronic components if the input volt-

age to the welder is too high (more than 40% over

rated voltage). If this fuse blows, the digital meters

will not light and the input contactor will not latch

when the Power On/Off Start pushbutton is

pressed and released.

5.

FUSE F2 — 1.5 amp gas, water, and high fre-

quency fuse protects the circuitry that drives the

gas and water valves and the high frequency sup-

ply transformer. If this fuse blows, the valves and

high frequency will not work. However, the LEDs

for Gas and Water and High Frequency will still

light.

6.

REMOTE RECEPTACLE — A six-pin circular con-

nector for an Arc Start switch or an Amptrol

remote current control.

7.

115 VOLT RECEPTACLE AND CIRCUIT BREAK-

ER — A duplex 15 amp grounded NEMA 5-15R

receptacle and 15 amp circuit breaker. Fifteen

amps of 115 volt AC power is available continu-

ously whenever the power is on. The circuit

breaker button will pop out if it trips. Reset by

pushing it in after the circuit breaker cools and the

overload has been removed.

8.

HIGH FREQUENCY INTENSITY CONTROL AND

SPARK GAP — This control changes the high fre-

quency intensity. Use the lowest intensity which

still gives good arc starting to minimize Radio

Frequency Interference (RFI). The spark gap is set

at the factory to the normal setting marked on the

cover plate. Instructions for larger or smaller gap

settings are also on the cover plate.

9.

GAS AND OPTIONAL WATER VALVES —

Solenoid valves that open at the beginning of the

Preflow time and close at the end of the Afterflow

time.

The gas valve inlet and outlet are standard 5/18-18

right-hand female fittings. The water valve inlet

and outlet are standard 5/8-18 left-hand female fit-

tings. The fittings conform to CGA (Compressed

Gas Association) standards. Use a water line

strainer to prevent particles from jamming the

water valve.

OPERATION

B-12

B-12

SQUARE WAVE TIG 355

Retur

n to Section TOC

Retur

n to Section TOC

Retur

n to Section TOC

Retur

n to Section TOC

Retur

n to Master TOC

Retur

n to Master TOC

Retur

n to Master TOC

Retur

n to Master TOC

CAUTION