F-26

F-26

POWER BOARD TEST

(continued)

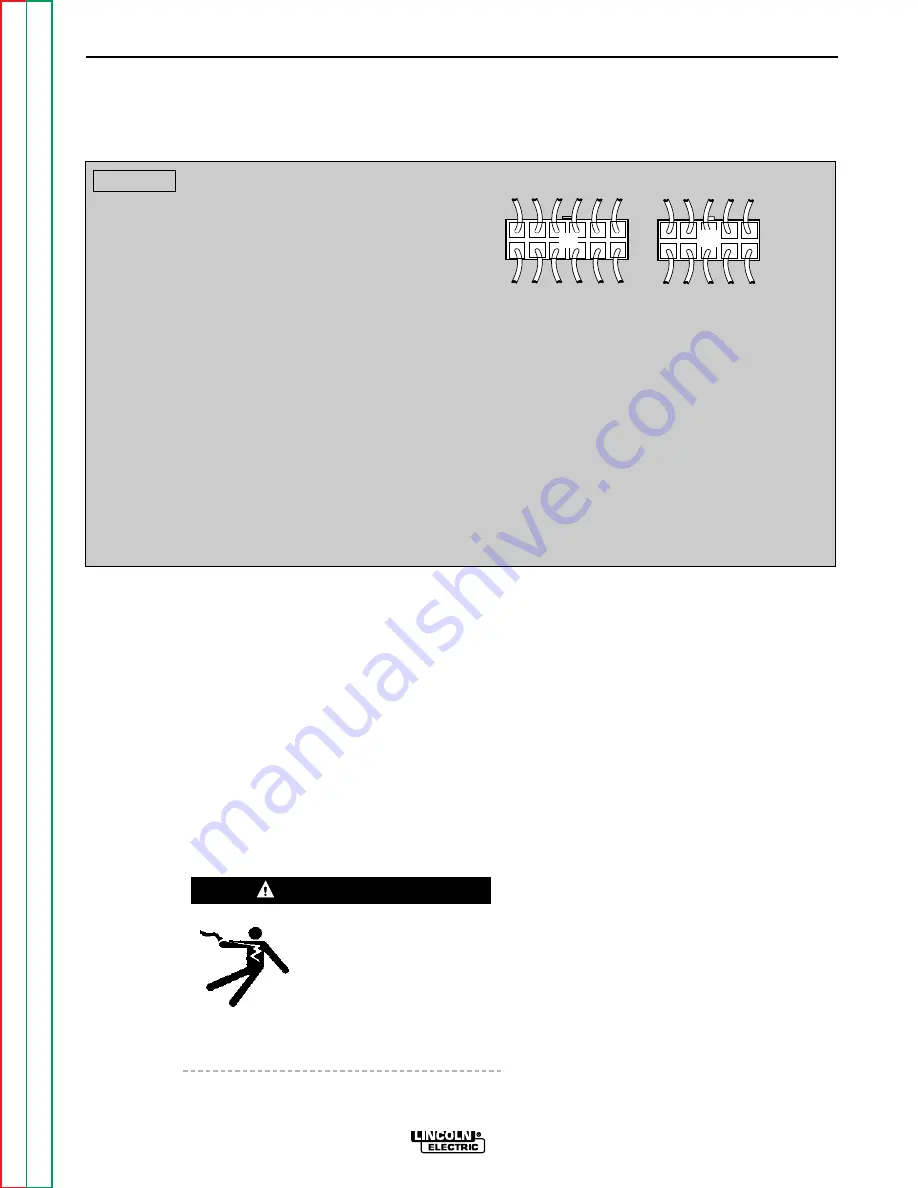

FIGURE F.4 - POWER BOARD TEST POINTS

TROUBLESHOOTING & REPAIR

TEST PROCEDURE

1. Remove input power to the machine.

2. With the 5/16" nut driver, remove the

screws and carefully lower the front control

panel.

3. On the power board, locate the test points

that are called out in the following Power

Board Voltage Test Chart. See Figure F.4.

4. Connect the volt/ohmmeter to each set of

test points and compare your reading to the

expected reading from the chart.

ELECTRIC SHOCK can kill.

•

With input power ON,

there are high voltages

inside the machine. Do

not reach into the machine

or touch any internal part

of the machine while

power is on.

• Apply power and press the start button.

• If the correct voltages are being applied

to the power board but NOT generated

by the power board, the power board

may be faulty.

• If the background voltages are NOT

being applied to the power board, the

control transformer, the background

rectifier, or the associated wiring may be

faulty.

5. After the tests are completed and the prob-

lem repaired, install the front control panel,

using the 5/16" nut driver.

SQUARE WAVE TIG 355

Retur

n to Section TOC

Retur

n to Section TOC

Retur

n to Section TOC

Retur

n to Section TOC

Retur

n to Master TOC

Retur

n to Master TOC

Retur

n to Master TOC

Retur

n to Master TOC

WARNING

G2081-[

]

SQUARE WAVE POWER

12 11 10 9

8

7

6

5

4

3

2

1

10 9

8

7

6

5

4

3

2

1

J2

J4