B-2

OPERATION

STATIFLEX

®

6000-MS

Automatic cleaning with the timer

In addition to the pressure drop cleaning, preset cleaning times

can be established. These times will signal clean ing whether the

fans are in operation or not. This allows for off-line cleaning as

well as maintenance of filters dur ing low-airflow operation. When

there is low airflow (only one or two arms in operation), the

pressure drop will be naturally low, even though dust accumulates

on the sur face. When higher airflow is used (all five arms are in

use), this residual dust may cause a higher pressure drop and

result in an alarm condition. In applications where this variability

may happen, as well as cutting operations, timed cleaning is

recommended.

DO NOT USE THE TIMER CLEANING DURING THE FIRST TEN HOURS

OF OPERATION!!

This allows the precoating powder to get

established on the surface of the filter. If a cleaning cycle is

initiated during this initial period, the precoating powder may not

be well estab lished on the cartridge and will result in lower

efficiency and shorter life.

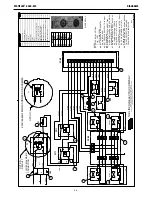

Timers can be set on the timer clock located in the con trol box.

The cleaning cycle will run continuously (factory set at one pulse

per minute) during the on time. The one minute interval can be

lengthened by adjusting the timer relay to the right of the clock

timer (off-time). One full revolution of the filters takes approx-

imately 60 pulses.

Adjusting the cleaning and pause time.

The cleaning and pause times for the pressure-drop activated

cleaning cycle are preprogrammed into the PC board software.

The times for the clock-timer operated cleaning, however, are

adjustable using the timer relay to the right of the clock timer. The

cleaning pulse time (upper dials) is pre-set to 1 second. This

should not be adjusted. The pause time has a minimum one

minute, but can be increased using the lower dials. For off-line

clean ing, longer pause times allow the fine dust to settle to the

drum.

Manual Cleaning

DO NOT INITIATE A CLEANING CYCLE DURING THE FIRST TEN

HOURS OF OPERATION!!

This allows the precoating powder to get

established on the surface of the filter. If a cleaning cycle is initiat -

ed during this initial period, the precoating powder may not be

well established on the cartridge and will result in lower efficiency

and shorter life.

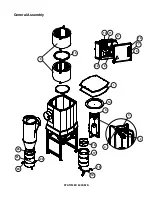

A full cleaning cycle (one complete revolution around the filter)

can be initiated by pressing the start/reset button on the control

box. During this time, the cleaning pulse will fire, the tank will

refill during a pause time, then the next section of the filter will be

cleaned. This will continue until the complete filter has been

cleaned. During the entire revolution, the indicator will light

continuously. The cycle can be stopped at any time by pressing

the start/reset button.

TImER SwITCH

I.) Features of the Device:

•

Two-channel version, mounting on DIN rail, terminals

•

Daily and weekly program in one device

•

Power supply 12-240 VAC / VDC

•

Functions: according to the user program, manual, random, and

holiday program modes.

•

100 memory places, illuminated LCD display

•

Operational back up – up to 3 years

•

Pulse and repeat cycle output

*

Before you start programming this timer switch, please

make sure to read carefully through the following

instructions.

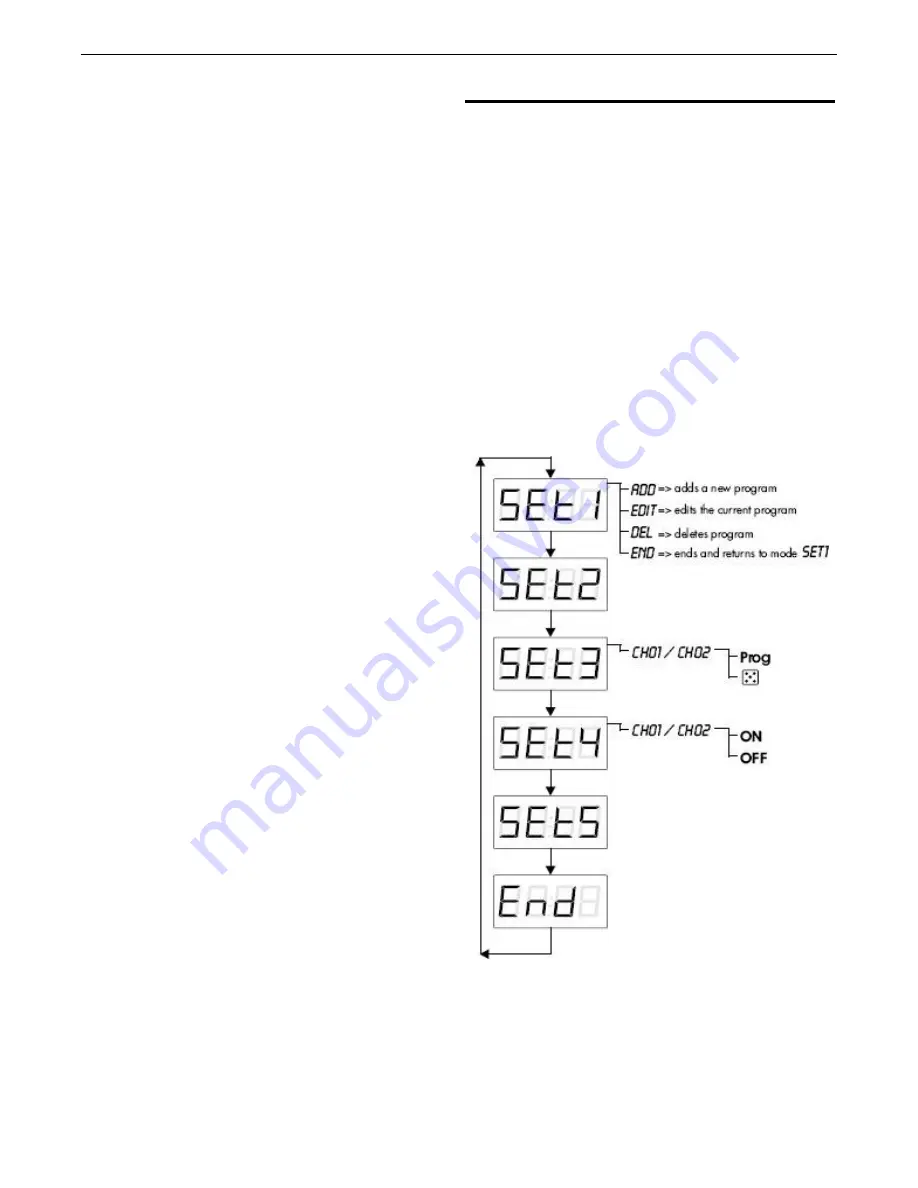

II.) Controls/Menu Description:

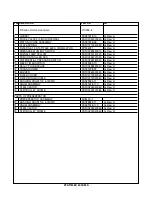

1.) Menu flow chart