D-2

MAINTENANCE

ROUTINE SERVICE & mAINTENANCE

To sustain optimal performance level, routine Service &

Maintenance of the System is required. it is recommended to

empty the Drums based on level of annual Consumable usage,

Type of welding process,

Condition of Base metal & Overall type of usage & air quality

extracted through the systems.

Statiflex 6000 Routine maintenance includes:

•

Check & clean the Preseparator aluminium mesh filters.

recommended to keep a supply of new preseperator filters to

allow zero system down time during cleaning routine.

•

Replace main filter catridge's if necessary

•

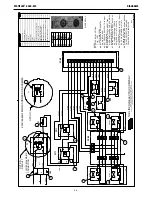

Check for correct cleaning system air pressure at filter units.

•

Check Statiflex 6000 control panel, ensure there is no Alarm

status & filter cleaning system is functioning properly.

CHANGING THE DUST BAG

The particulate matter collected may be dangerous to

your health. Take necessary precautions so that you and

your fellow workers do not breathe the dust and

particulate. Wear a suitable respirator when disposing of

the particulate.

When using the Weld fume Extraction or local exhaust

Ventilation (LEV) equipment, sparks from welding,

Cutting or grinding Process can cause fire with in the

equipment. To minimize the potential fire, operation,

service 7 maintenance guidelines for fume extraction or

LEV equipment should be followed..

Check with local authorities for regulations governing the

disposal of this material.

Turn off all fans before opening or inspecting the drums or filters.

Open the lever lock carefully & pull the drum using the handle

underneath the filter unit (or preseparator). Tie off the opening of

the bag before removing from the drum; slowly remove the bag.

SEE WARNING ABOVE.

Install a new bag, replace the drum, seal

tightly. Check with local authorities for regulations governing the

disposal of this material. SEE WARNINGS ABOVE.

REPLACING THE FILTER CARTRIDGES

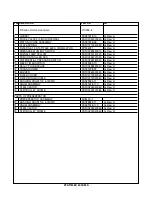

Replace the filter cartridges when they have been damaged or

when the indicator shows that the filter is clogged. The filter

indicator will flash slowly and the alarm buzzer will sound if the

cleaning function does not reduce the pressure drop below the set

point after 240 pulses (-4 hours). This could be due to a saturat ed

filter, Jack of compressed air, low air pressure, cleaning

equipment malfunction or dirt, oil or moisture in the compressed

air . Oil or moisture in the inlet airstream will also greatly reduce

the life of the filter.

Improper maintenance of the filter unit such as operating with fully

saturated main filter over extended period of time may reduce

equipment life, filter efficiency & increase chance of over heating

blower motors & potential fire hazard.

If routine service & maintenance is not performed, appli-

cations & process with oils, anti spatter, tip-dip and/or

moisture may cause damage to the system equipment,

CFM level & may void the equipment & filter warranty.

Check with local authorities for regulations governing the

disposal of this material.

1. Turn off all fans connected to the system.

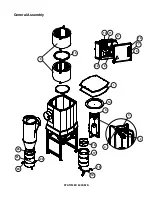

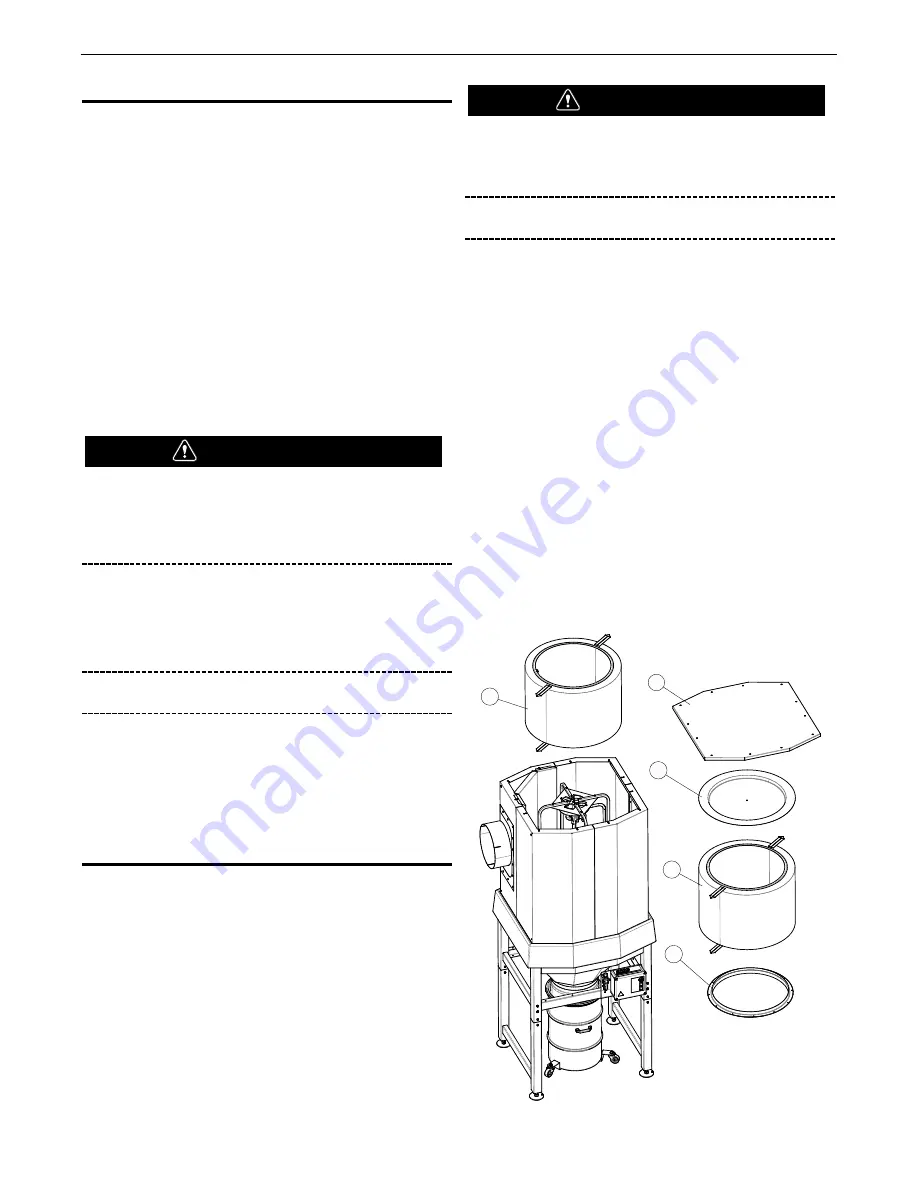

2. Remove the top lid of the Statiflex 6000-MS (B) and remove the

filter cover (C).

3. Remove the top filter (D) by pulling up on the two straps on the

filter.

4. Remove the intermediate ring that seals the two filters together

(E).

5. Remove the second filter by pulling up on the two straps (F).

6. When unpacking a new filter, notice that the filter has been

treated with precoating powder. Some of this powder may have

settled to the bottom of the packaging.

7. Install a new filter, the intermediate ring and a new filter on top

of the intermediate ring.

8. Replace the filter cover and lid. Be sure that all components are

properly seated and sealed.

9. Do not use the cleaning system during the first 10 hours of

operation to allow the precoating powder to establish on the filter

surface. Excess powder found in the packaging can be added to

the airstream when the filters are installed.

WARNING

WARNING

%

&

'

(

$

STATIFLEX

®

6000-MS