Torchmate 5100

36

Accessory Toggle

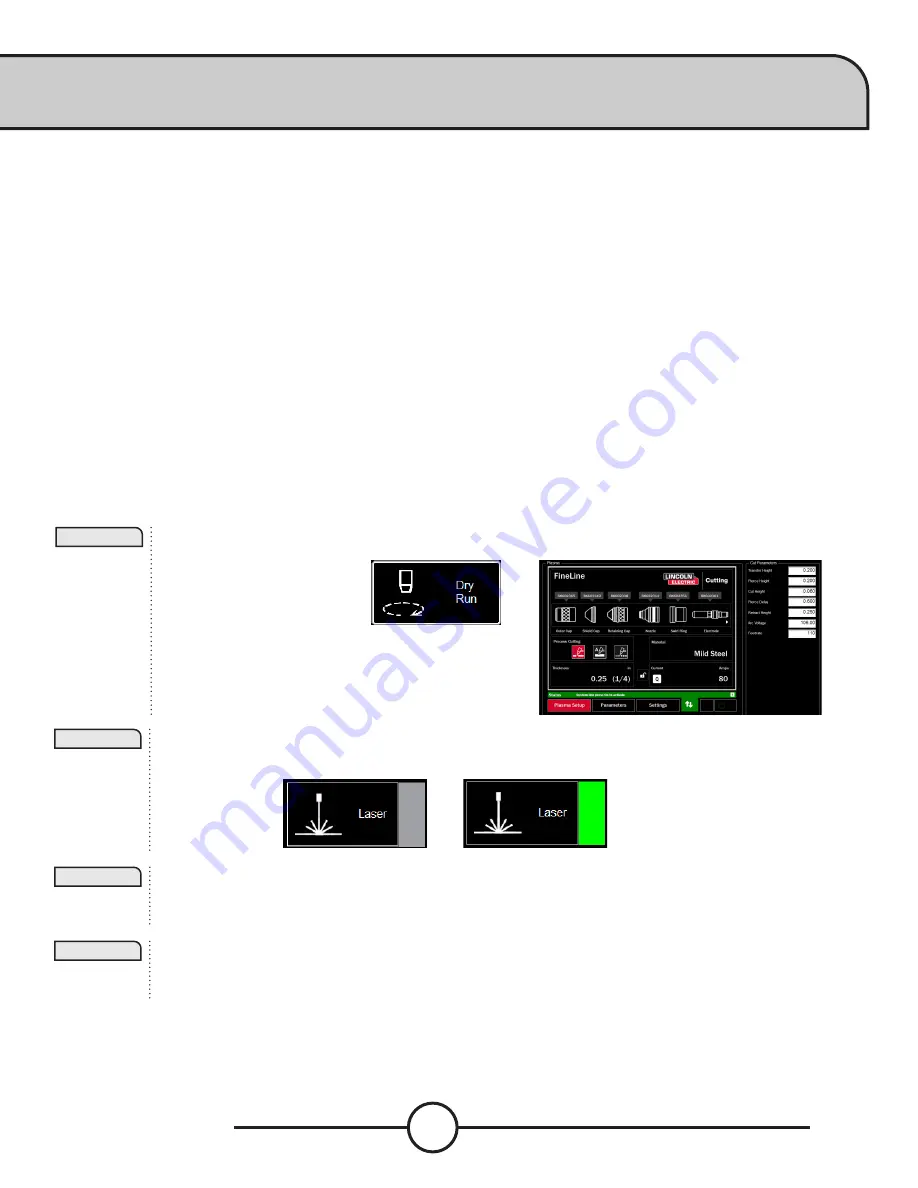

The accessory panel hosts the added accessories toggle buttons. These added toggle buttons are not visible unless

commissioned through the OPTIONS PANEL. NOTE: The laser is not available with BEVEL machine configurations.

Laser Operation:

The Laser Plate Finder is intended to aid an operator at the control console to locate the centerline position of the torch

body on the surface of the material by projecting a red laser dot onto it. This can assist in the locating of the PLATE ORIGIN

position, performing Plate Alignments, as well as performing a dry run with the laser indicating the cut position of the part.

It is critical to the proper function of this attachment that the torch position be set properly and the material thickness be

defined before setting program zero, performing a plate alignment, or running a program using DRY RUN with the laser

enabled.

How the Laser Works:

The laser is positioned at a slight angle to the torch, so that it crosses directly under its centerline. With the torch

positioned properly on the machine and the material thickness entered into the system, the z axis will make a position

adjustment when activated so that the projected dot will land on the surface of the material underneath the centerline of

the torch.

The laser can only be activated when the system is switched to the Dry Run mode, but will automatically turn itself off

when the system is set to Active Run, and a part program is executed.

Step 1:

Step 2:

Step 3:

Step 4:

In the PROCESS SETUP tab, enter the thickness of material and the proper amperage.

Toggle to DRY RUN.

Toggle the LASER ON. The button will display GREEN. The head will move down to the proper position and

illuminate the laser.

Move the head and use the indicator for setting PLATE ORIGIN, setting plate alignment, dry run a job, or for

visualizing a point on the plate.

Once done using the laser, toggle the laser to OFF.

By changing to ACTIVE RUN, the laser will power off automatically.

Summary of Contents for Torchmate 5100 Series

Page 1: ...March 31 2021 Copyright 2021 Lincoln Electric Cutting Systems USERGUIDE ...

Page 84: ......

Page 85: ......

Page 86: ......