INSTALLATION

A4.7

A4.7

VANTAGE® 500

WELDING OUTPUT CABLES

With the engine off, route the electrode and work

cables through the strain relief bracket provided on the

front of the base and connect to the terminals provided.

These connections should be checked periodically and

tightened if necessary.

Listed in Table A4.1 are copper cable sizes recom-

mended for the rated current and duty cycle. Lengths

stipulated are the distance from the welder to work and

back to the welder again. Cable sizes are increased for

greater lengths primarily for the purpose of minimizing

cable voltage drop.

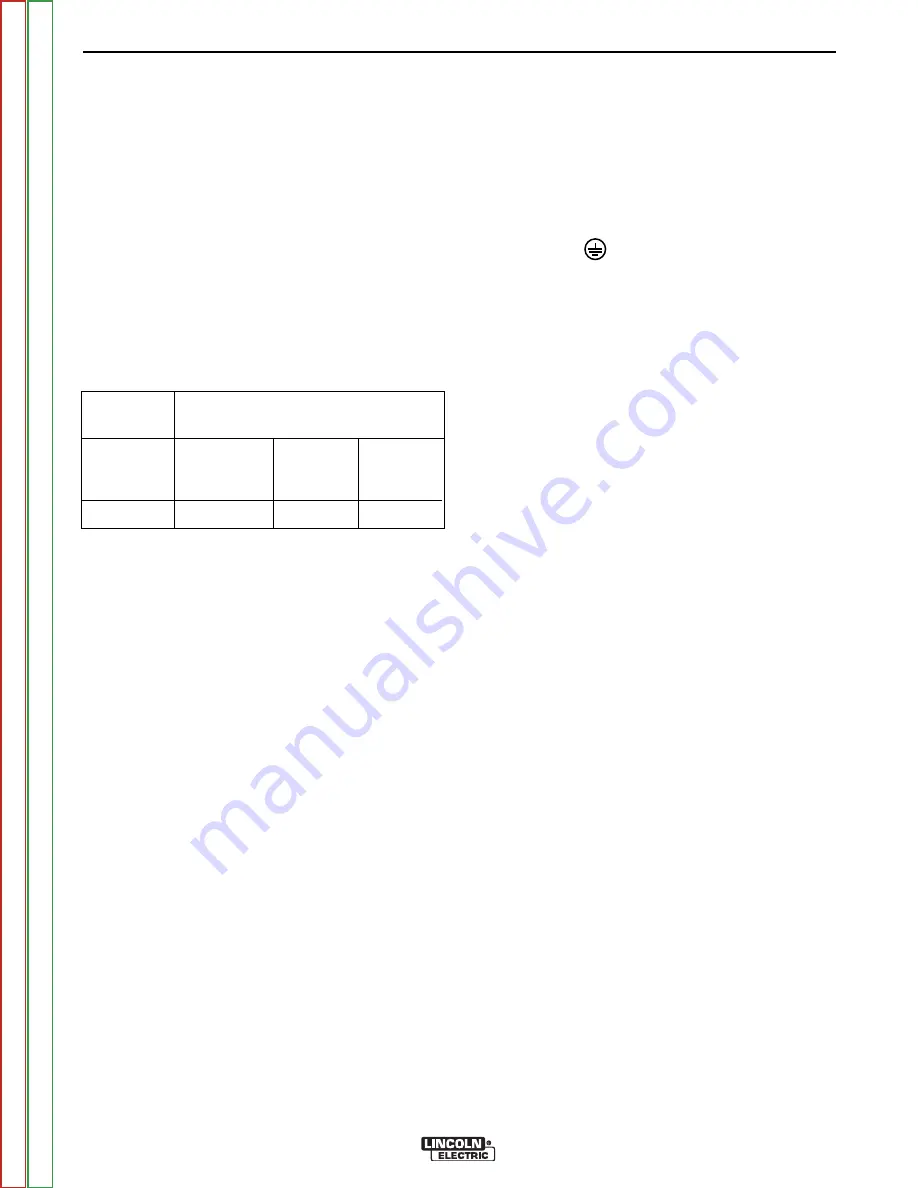

TABLE A4.1 – COMBINED LENGTH OF

ELECTRODE AND WORK CABLES

Total Combined Length of

Electrode and Work Cables

Amps

@ 100%

Duty Cycle Up to 150 ft. 150-200 ft. 200-250 ft.

500

3/0 AWG

3/0 AWG

4/0 AWG

MACHINE GROUNDING

Because this portable engine driven welder creates its

own power, it is not necessary to connect its frame to

an earth ground, unless the machine is connected to

premises wiring (home, shop, etc.).

To prevent dangerous electric shock, other equipment

powered by this engine driven welder must:

a) be grounded to the frame of the welder using a

grounded type plug,

or

b) be double insulated.

When this welder is mounted on a truck or trailer, its

frame must be securely connected to the metal frame

of the vehicle. When this engine driven welder is con-

nected to premises wiring such as that in a home or

shop, its frame must be connected to the system earth

ground. See further connection instructions in the sec-

tion entitled

Standby Power Connections

as well as

the article on grounding in the latest U.S. National

Electrical Code and the local code.

In general, if the machine is to be grounded, it should

be connected with a #8 or larger copper wire to a solid

earth ground such as a metal water pipe going into the

ground for at least ten feet and having no insulated

joints, or to the metal framework of a building which has

been effectively grounded. The U.S. National Electrical

Code lists a number of alternate means of grounding

electrical equipment. A machine grounding stud

marked with the symbol is provided on the front of

the welder.

AUXILIARY POWER RECEPTACLES

The auxiliary power capacity of the Vantage 500 is

12,000 watts of 60 Hz, single-phase power. The auxil-

iary power capacity rating in watts is equivalent to volt-

amperes at unity power factor. The maximum permis-

sible current of the 240 VAC output is 50 A. The 240

VAC output can be split to provide two separate 120

VAC outputs with a maximum permissible current of

50 A per output to two separate 120 VAC branch cir-

cuits. The output voltage is within ± 10% at all loads up

to rated capacity.

NOTE:

The 120/240V receptacle has two 120V outlets

of different phases and cannot be paralleled.

The Vantage has two 20A-120VAC (5-20R) duplex

receptacles and one 50A-120/240 VAC (14-50R)

receptacle. The 120/240 VAC receptacle can be split

for single-phase 120 VAC operation. The auxiliary

power receptacles should only be used with three-wire

grounded type plugs or approved double insulated

tools with two-wire plugs. The current rating of any plug

used with the system must be at least equal to the cur-

rent capacity of the associated receptacle.

STANDBY POWER CONNECTIONS

The Vantage 500 is suitable for temporary, standby or

emergency power using the engine manufac turer’s

recommended maintenance schedule.

The Vantage 500 can be permanently installed as a

standby power unit for 240 volt, three-wire, 50 amp ser-

vice. Connections must be made by a licensed electri-

cian who can determine how the 120/240 VAC power

can be adapted to the particular installation and com-

ply with all applicable electrical codes. The following

information can be used as a guide by the electrician

for most applications. Refer to the connection diagram

shown in

Figure A4.1.

Return

to

Section

T

OC

Return

to

Section

T

OC

Return

to

Section

T

OC

Return

to

Section

T

OC

Return

to

Master

T

OC

Return

to

Master

T

OC

Return

to

Master

T

OC

Return

to

Master

T

OC