THEORY OF OPERATION

E-2

E-2

VANTAGE® 500

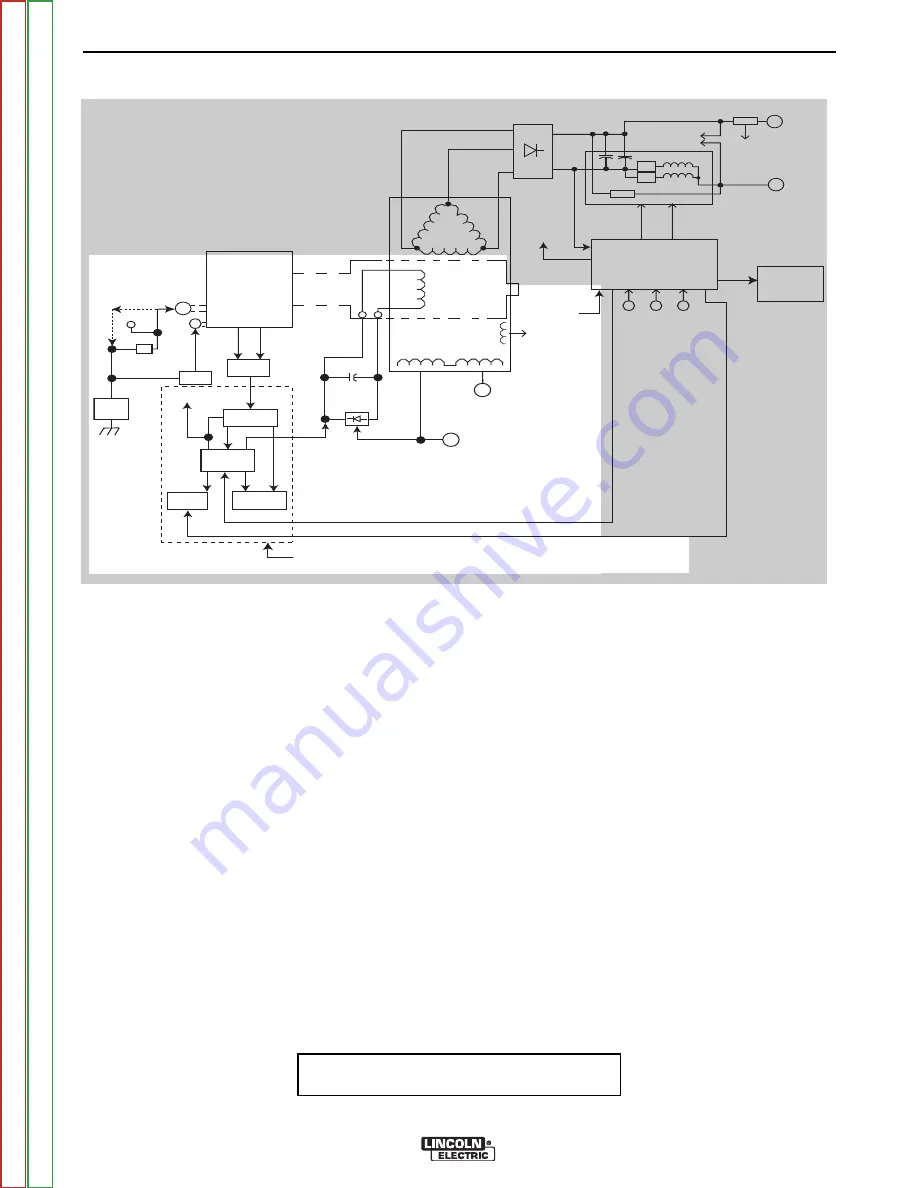

FIGURE E.2 - BATTERY, ENGINE, ROTOR, PULL COIL BOARD

AND PERIPHERAL BOARD (ENGINE PROTECTION

NOTE: Unshaded areas of Block Logic

Diagram are the subject of discussion

GENERAL DESCRIPTION

The Vantage 500 is a diesel engine-driven welding

power source capable of producing 500 amps at

40VDC at a 100% duty cycle. The engine is coupled to

a brush-type alternating current generator. This AC out-

put is rectified and controlled by

Chopper Technology

to produce DC current for multi-purpose welding appli-

cations. The Vantage 500 also provides auxiliary power

of various voltage and wattage levels depending on the

Code number. See the appropriate Wiring Diagram or

Technical Specifications.

BATTERY, ENGINE, ROTOR,

STATOR, PULL COIL BOARD AND

PERIPHERAL BOARD – ENGINE

PROTECTION

The 12VDC battery powers the engine starter motor

and also supplies power to the Pull Coil PC board,

Peripheral PC board and associated circuitry. When the

engine, which is mechanically coupled to the rotor, is

started and running, the 12 VDC battery voltage is fed

momentarily through the pull coil PC board to the rotor

field coil via a brush and slip ring configuration.

This excitation or "flashing" voltage magnetizes the

rotor lamination. This rotating magnet induces a volt-

age in the stationary windings of the main alternator sta-

tor. A 120VAC supply from the stator is fed through a

rectifier and filter to supply the rotor with a steady DC

voltage. The stator also houses a three-phase weld

winding, a 120/240VAC single-phase auxiliary winding,

In some codes, there is also a 3 phase auxiliary and a

separate 120VAC and/or a 42VAC wire feeder power

supply that is routed to the 14 pin MS typel Connector.

The engine alternator supplies charging current for the

battery circuit. The Peripheral board monitors the

engine sensors and will shut the engine off in the event

of low oil pressure, engine over temperature, malfunc-

tion of the engine’s alternator system or a low fuel con-

dition. The idler solenoid, if present, is mechanically

connected to the engine’s throttle linkage. If no welding

or auxiliary current is being drawn from the Vantage

500, the Pull Coil board activates the idler solenoid,

which then brings the engine to a low idle state. When

output current is sensed (either weld or auxiliary), the

Weld Control PC board deactivates the idler solenoid,

and the engine goes to high RPM.

ENGINE

ROTOR

STATOR

AUXILIARY

WINDINGS

W

E

L

D

W

I

N

D

I

G

MECHANICAL

ROTATION

ALTERNATOR

OUTPUT

CONTROL

MODE

SELECT

SWITCH

SLIP

RINGS

ARC

CONTROL

WELD

CONTROL

BOARD

VOLTMETER

AMMETER

42 VAC and 120VAC

to 14 Pin Amphenol

for Wire Feeder

(No 120 VAC on EURO Models)

THREE-PHASE

RECTIFIER

+

+

+

+

__

__

TO WELD

CONTROL

BOARD

_

_

START

BUTTON

+

BATTERY

ON

STARTER

+12 VDC

RUN

ENGINE

SENSORS

OIL

PRESSURE

WATER

TEMP.

PERIPHERAL

PCB

PULL

COIL

PCB

+12 VDC

RUN

FUEL

SOLENOID

PULL

HOLD

FLASHING

IDLER

SOLENOID

LOW IDLER SIGNAL (TO SUPPLY PULL VOLTS)

HOLD VOLTS FROM CONTROL PCB

25

•

(COLD)

120 VAC

RECEPTACLES

(Not on EURO Machnes)

AC RECEPTACLES

Various combinations of

1Ø and 3Ø Outputs.

See Techincal Specs.

IGBT

IGBT

CHOKE

R4-50

•

2-POWER MODULES

SHUNT

TO

CONTROL

PCB

AUX. POWER

USE SENSING

+12VDC

RUN

80 VDC

PWM

SIGNAL

PWM

SIGNAL

120V

AC

160VDC

120VAC

PULL

RUN/STOP

SWITCH

* On some codes the Peripheral Board, Pull Coil Board, Idler Solenoid & Fuel Solenoid are

replaced by an Electronic Governor Control module and components. See Wiring Diagram.

Return

to

Section

T

OC

Return

to

Section

T

OC

Return

to

Section

T

OC

Return

to

Section

T

OC

Return

to

Master

T

OC

Return

to

Master

T

OC

Return

to

Master

T

OC

Return

to

Master

T

OC