D-2

TROUBLESHOOTING

D-2

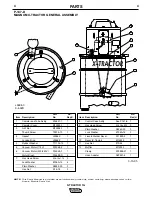

X-TRACTOR 1G

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local

Lincoln Authorized Field Service Facility

for technical troubleshooting assistance before you proceed.

CAUTION

PROBLEMS

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENTS(S)

RECOMMENDED

COURSE OF ACTION

No Smoke Pickup

Motor won’t operate in any mode.

1.Be sure all tubing connections are

tight and there are no punctures in

hose.

2. Control relay not connected.

Control leads #31 and #4 must be

energized for full power.

3.Filter needs cleaning.

4.Plugged or damaged welding gun.

Refer to appropriate IM manual for

gun maintenance.

1.Verify power to the unit.

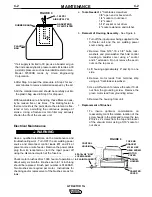

2.Check motor brushes and replace

if necessary.

Contact your

Local Lincoln Authorized

Field Service Facility

for technical

troubleshooting assistance.

Summary of Contents for X-TRACTOR 1G

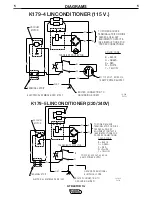

Page 21: ...5 DIAGRAMS 5 X TRACTOR 1G 0 0...