Impinger II – Installation & Operation Manual

13

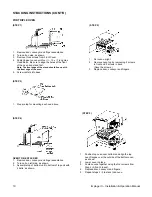

Back view of two Impinger

®

II Gas Ovens showing

Gas Valve Installation and piping spacing.

Back view of three Impinger

®

II Gas Ovens showing

Gas Valve Installation and piping spacing.

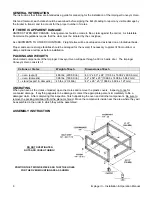

UTILITY SERVICE LAYOUT

Gas and electrical services for the Models 1116 and 1117 should be located as shown below. If flexible services

are provided, they must meet code requirements for such installation.

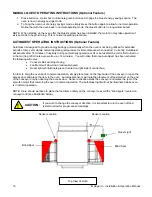

INSTALLATION CODES AND GUIDELINES

GAS INSTALLATION

Safe and satisfactory operation of this oven depends to a great extent upon its proper installation, and it should be

installed, as applicable in accordance with the National Fuel Gas Codes, ANSI Z223.1/NFPA 54 latest version,

Manufacturers’ Installation Instructions and local municipal building codes, ISO 203-1.

1. The oven and its individual shut off valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of ½ psig (3.45kPa).

2. The oven must be isolated from the gas supply piping system by closing its individual manual shut off

valve during any pressure testing of the gas supply system at test pressures equal to or less than ½

psig (3.45kPa).

IN MASSACHUSETTS:

The minimum length of a flexible gas supply hose is thirty-six (36”) inches.

IN CANADA:

The installation of these appliances is to be in accordance with CSA B.149.1 latest version – Natural

Gas and Propane Installation Code – and/or Local Codes.

IN AUSTRALIA:

Adhere to AG 5601-2004 and 4563-2004 Gas Installation Code.