9

OPERATION

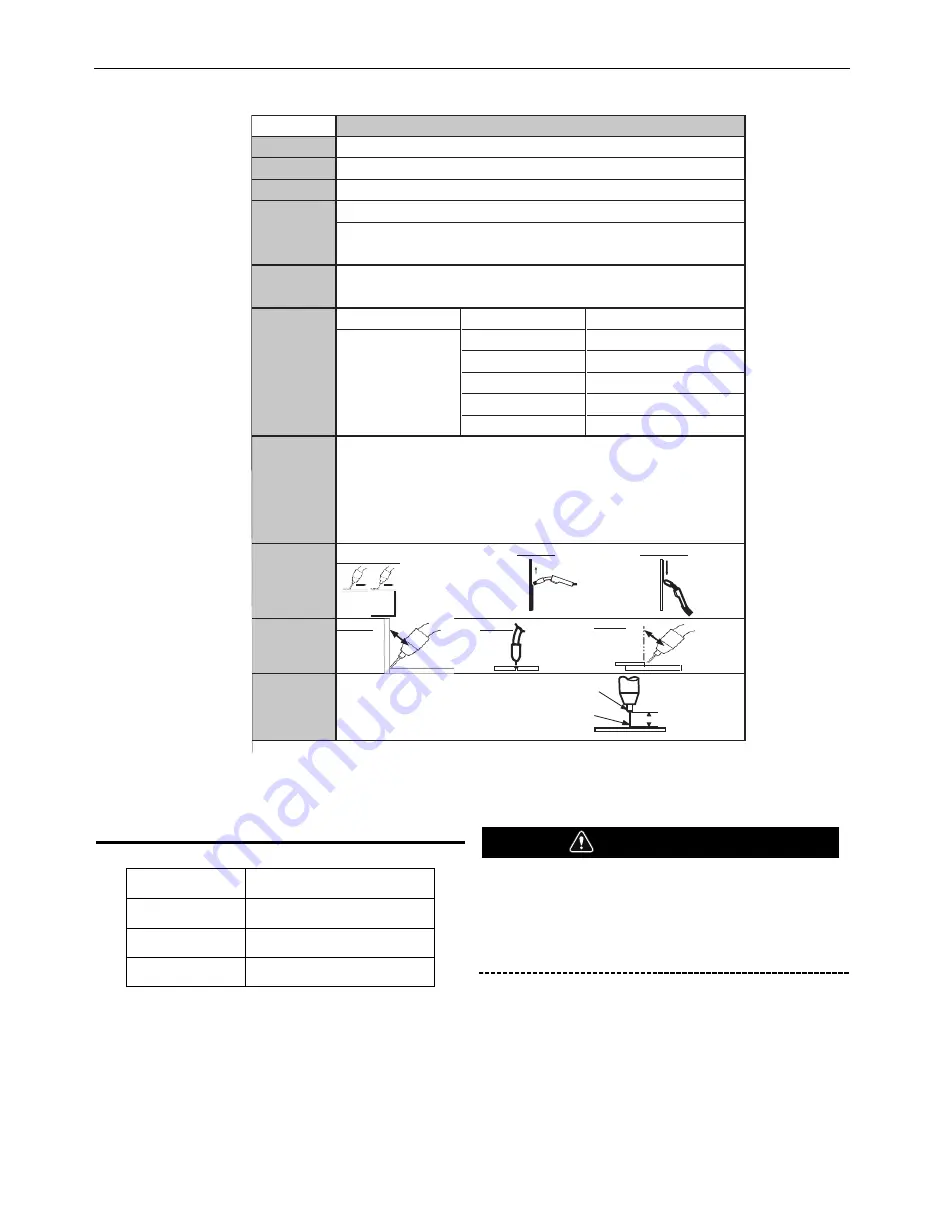

TABLE B.1

rePlace Parts list

Use of this unit on thicker materials than recommended may

result in welds of poor quality. The welds may appear to be

fine, but may lack the fusion or bonding necessary to give a

strong weld. This is called "Cold Casting" or "cold lapping"

and is some what similar to a cold solder joint. Weld failure

may result.

Contact Tip (.035”)

KH712 (.035” / 0.9MM)

Drive Roll

KP4364-035

Nozzle

KH726

FCAW Wire

LINCOLN .035 NR-211-MP

WARNING

FC-90

Welding Wire

Contact Tip

Drive Roll

Horizontal: "Drag"

Tee Joint

Maintain an electrode Stickout

of 3/8" while welding.

Wire Feed

Tension

.035 (0.9mm) - Lincoln Part No. KH712

0.9mm Knurled groove - Lincoln Part No. KP4364-035

The suggested Wire Feed Speed settings in the table below are based on a midrange wire tension

setting. The tension may be changed if required to improved wire feeding; however, the WFS setting may

have to be adjusted from the values in the table below.

Do NOT weave the arc, neither forward, backward, or sideways

16 Ga Steel

FCAW -Gasless (Flux Cored)

.035 Lincoln NR-211-MP (Innershield Cored Wire)

Heat Range

Wire Feed Speed

Loading The

Wire

Suggested

Settings For

Welding

Remember: Remove the contact tip prior to loading wire

Keep tension on the wire to prevent unspooling.

1. Cutoff the bent portion of the wire and straighten the first 4" for feeding into rolls and gun.

2. Release spring loaded pressure arm and rotate the Idle Roll Arm away from Drive Roll.

3. Thread wire through the guide tube, over drive roll and into gun liner. Close Idle Roll arm.

6

5

Steel Thickness

18 Ga Steel

6.5

7.5

6

7

8

8.5

R

Weld at a Steady Pace

8.5

14 Ga Steel

12 Ga Steel

8

Helpful Hints

1/8" Steel

For Horizontal Weld Joints, remember: "Drag if there’s Slag"

Refer to Manual for Troubleshooting Poor Weld Quality

Remove Slag with the Chipping Hammer to expose weld

Proper Gun

Angles for

common Weld

Joint Types

Direction of

Welding AND

Angle of Gun

relative to Weld

Direction

Electrical

Stickout

CONTACT TIP

ELECTRODE

3/8

Vertical Down

Butt Joint

Lap Joint

Vertical Up

45°

45°