Page Number - 6

Form 420234

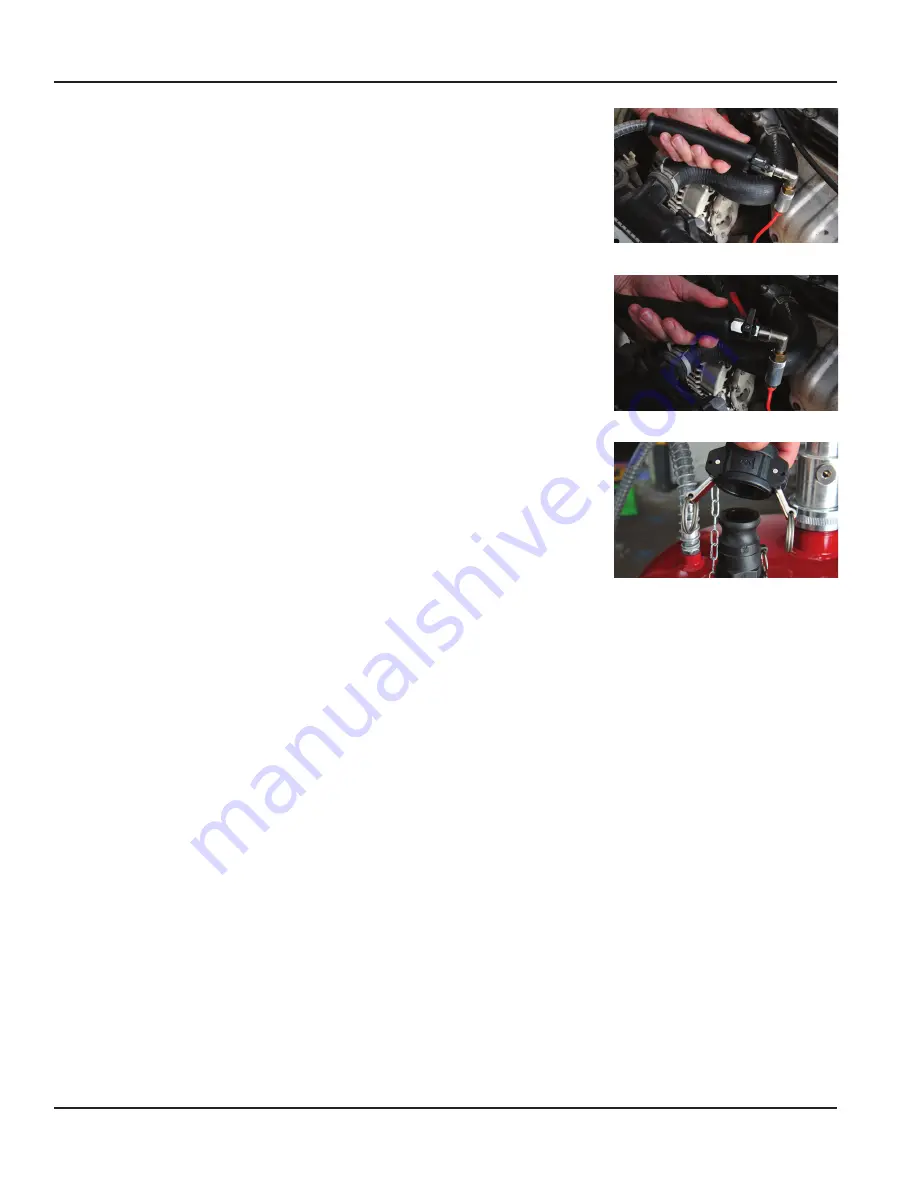

eMPtYinG tHe evacUatOr

1. Open valve A and/or valve B to bleed off any residual vacuum in

the tank, and allow air to flow into the tank as fluid is evacuated.

2. Remove the cap from the male camlok connector extending

from the top the evacuator tank (Fig. 9).

3. Connect the suction/evacuation hose from a diaphragm pump

or other type of centralized fluid evacuation system to the male

camlok connector.

4. Activate the pump system to remove the used fluid from the

evacuator tank.

5. When the evacuator tank is empty, turn off the pump, discon-

nect the suction/evacuation hose, and replace the camlok cap.

trOUBlesHOOtinG

No vacuum is being developed

1. Check the air pressure to the venturi. It must

be at least 90 PSI (6 bar).

2. Ensure the valve at the end of the evacuation hose is closed.

3. Ensure the valve between the venturi and the tank is open.

4. Damaged gauge – replace if necessary.

5. Ensure the muffler at the outlet of the venturi

is not clogged or restricted.

Vacuum gauge is not functioning

1. Replace the vacuum gauge if it has been bumped or damaged

2. Remove the gauge and check that the inlet is not blocked

Fluid will not evacuate

1. Ensure the valve at the end of the evacuation hose is open.

2. If evacuating oil, warm it up to at least

150° F (70° C).

3. Evacuation wand may be against bottom of reservoir. Lift the

wand out a little.

4. Check the evacuation wand for obstruction.

Unit will not maintain vacuum

1. Check the evacuation hose and fittings

for leaks.

2. Check the o-rings in the evacuation hose to wand connection.

Replace if worn.

3. Ensure the caps are tight.

4. Check the valve between the venturi and tank to ensure it is

closed and functioning properly.

fig. 7

fig. 8

fig. 9