Page Number - 6

FlowMaster

®

Rotary Driven Electric Pump

Form 404059

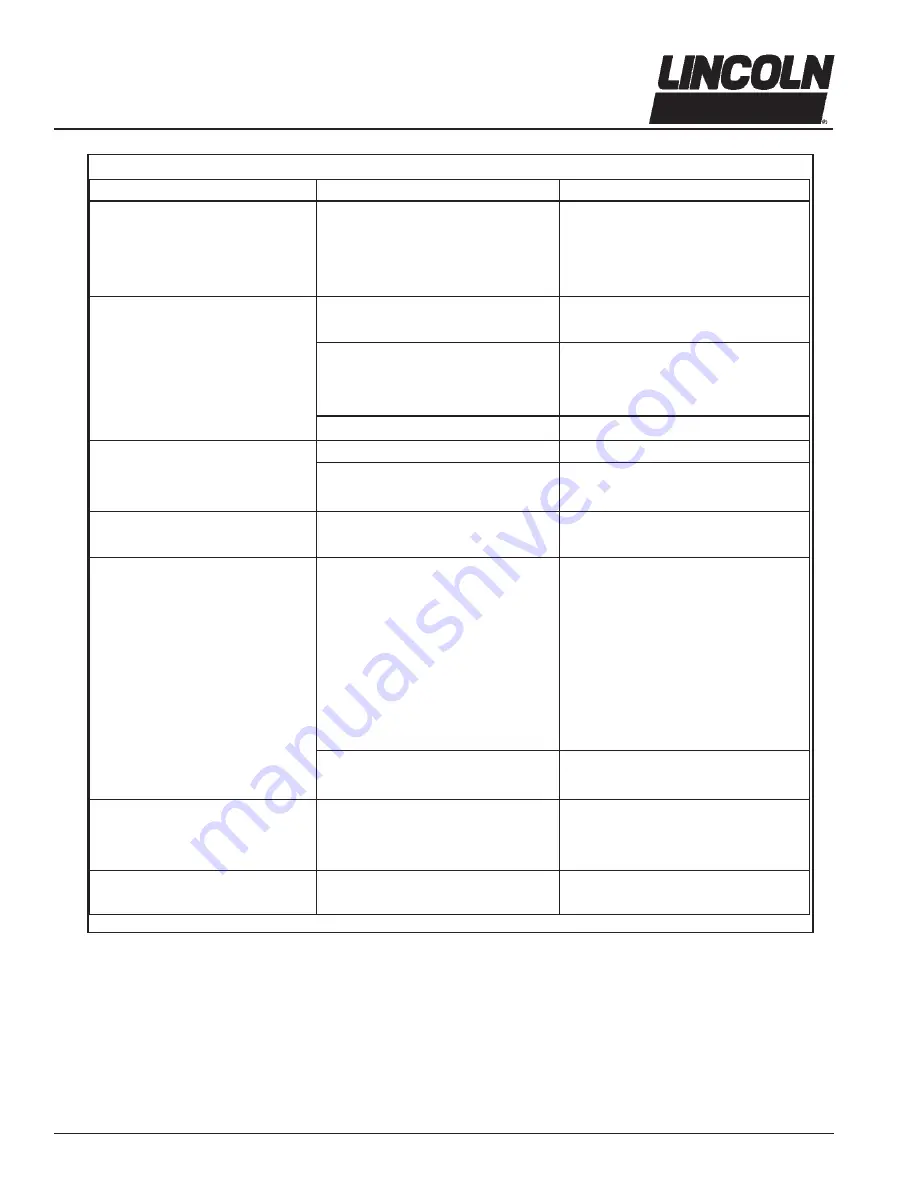

Troubleshooting

Condition

Possible Cause

Corrective Action

Pump does not run.

Pump is seized or damaged.

Dismantle the pump and repair

defective or seized component. See

disassembly and assembly

procedure.

Pump speeds up or runs erratically. Low level of grease or reservoir

Refill reservoir.

is empty.

Follower plate is stuck and separated

Check follower plate and container

from grease.

for damage.

Pump piston or checks are worn.

Disassemble the pump and repair.

Pump runs, but output is low.

Pump speed set too low.

Increase motor speed setting.

Faulty inlet (25, 27), faulty dischargee Replace faulty components.

check (18, 19) or damaged o-rings (26).

Weepage from housing cover 30.

Cup seal (15) or O-Ring (13b) wore out. Check the seals and replace if

necessary.

Pump becomes noisy.

No crankcase oil.

Add crankcase oil. Remove crankcase

cover (30a) from Pump Housing (67).

Oil level should be at the middle of

the crankshaft (37). Check dipstick

to verify

If unit is used in cold climates, use

Mobil Arrow HFA Hydraulic Oil in

crankcase.

Worn wrist pin bushing (12).

Check the bushings and replace if

necessary.

Pump does not build pressure.

Foreign material holding lower

Dismantle & clear check. Consider

check open.

installing inlet screen 272180

before returning pump to service.

Motor runs, but no pump output.

Gearset or adapter shaft stripped or

Dismantle and replace damaged

broken.

part.