English

English

7

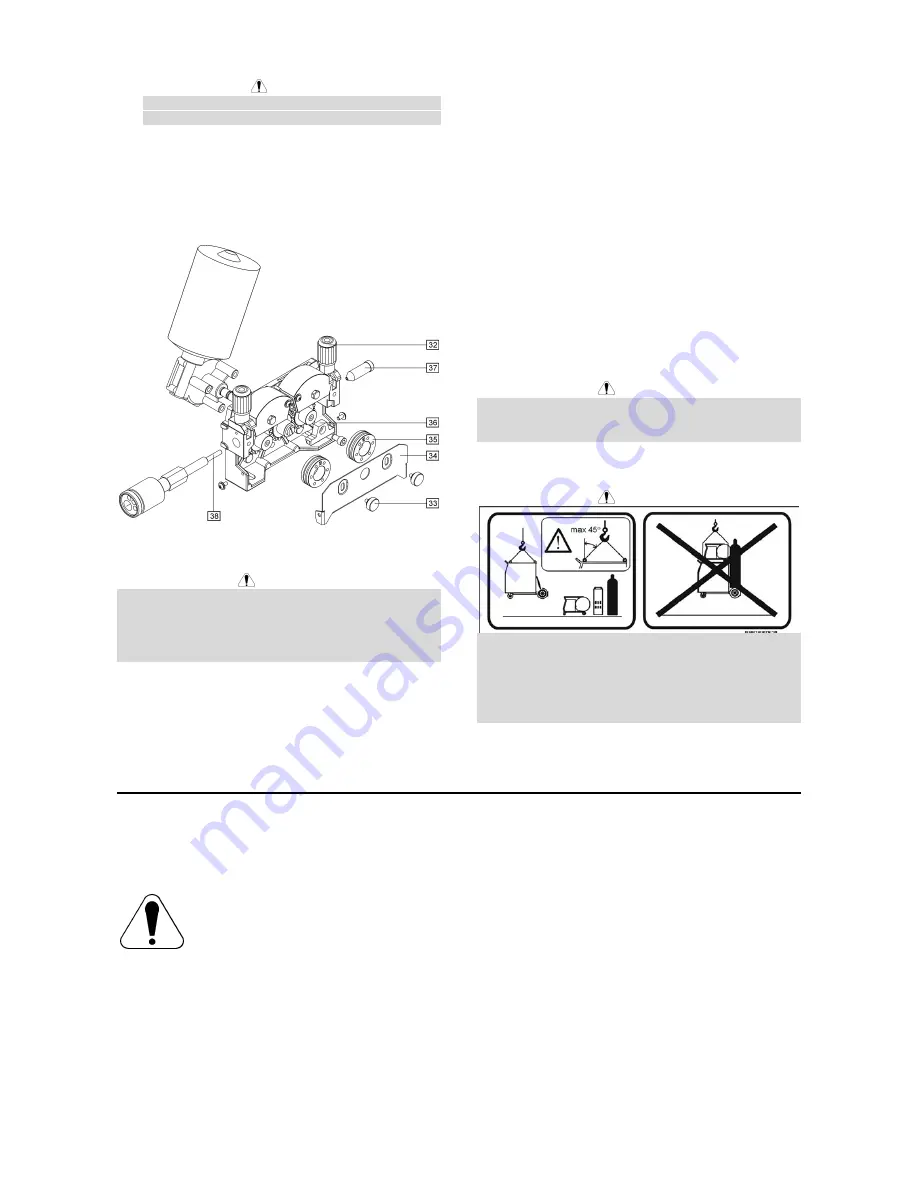

WARNING

For wires with the diameter greater than 1.6mm, the

following parts are to be changed:

•

The guide tube of the feeding console [36] and

[37].

•

The guide tube of the Euro socket [38].

•

Replace and tighten the protection cover [34] to the

drive rolls.

•

Screw the protection cover by fastening screws [33].

Maintenance

WARNING

For any maintenance or repair operations it is

recommended to contact the nearest technical service

center or Lincoln Electric. Maintenance or repairs

performed by unauthorized service centers or personnel

will null and void the manufacturers warranty.

The frequency of the maintenance operations may vary

in accordance with the working environment where the

machine is placed.

Any noticeable damage should be reported immediately.

Routine maintenance (everyday)

•

Check cables and connections integrity. Replace, if

necessary.

•

Remove the spatters from the welding gun nozzle.

Spatters could interfere with the shielding gas flow

to the arc.

•

Check the welding gun condition: replace it, if

necessary.

•

Check condition and operation of the cooling fan.

Keep clean its airflow slots.

Periodic maintenance (every 200 working hours

but not more rarely than once a year)

Perform the routine maintenance and, in addition:

•

Keep clean the machine. Using a dry ( and low

pressure) airflow, remove the dust from the external

case and from inside of the cabinet.

•

Check and tighten all screws.

WARNING

Mains supply network must be disconnected from the

machine before each maintenance and service. After

each repair, perform proper tests to ensure safety.

Transport

WARNING

To ensure safety transport it is necessary to:

•

Lift only power source without gas cylinder, cooler

and wire feeder.

•

Screw down an eye bolt and apply load axially in 45

degree angle in accordance to the drawing.

•

Ensure equal length of lifting lines.

Electromagnetic Compatibility (EMC)

11/04

This machine has been designed in accordance with all relevant directives and standards. However, it may still generate

electromagnetic disturbances that can affect other systems like telecommunications (telephone, radio, and television) or

other safety systems. These disturbances can cause safety problems in the affected systems. Read and understand

this section to eliminate or reduce the amount of electromagnetic disturbance generated by this machine.

This machine has been designed to operate in an industrial area. To operate in a domestic area it is necessary to

observe particular precautions to eliminate possible electromagnetic disturbances. The operator must

install and operate this equipment as described in this manual. If any electromagnetic disturbances are

detected the operator must put in place corrective actions to eliminate these disturbances with, if

necessary, assistance from Lincoln Electric.

Before installing the machine, the operator must check the work area for any devices that may malfunction because of

electromagnetic disturbances. Consider the following.

•

Input and output cables, control cables, and telephone cables that are in or adjacent to the work area and the

machine.

•

Radio and/or television transmitters and receivers. Computers or computer controlled equipment.

•

Safety and control equipment for industrial processes. Equipment for calibration and measurement.

•

Personal medical devices like pacemakers and hearing aids.

•

Check the electromagnetic immunity for equipment operating in or near the work area. The operator must be sure

that all equipment in the area is compatible. This may require additional protection measures.