English

English

5

•

When the weld is stopped, the Cooler continues to

run for about 5min., after this time, it is automatically

switched off.

•

If the weld is restarted in a time lower than 5min.,

the Cooler continues to run.

The POWERTEC 425C PRO has the possibility to

switch the automatic work of the water cooler off and set

it in continuously work. If it is necessary to change the

water cooler kind of work, you should:

•

Switch off the POWERTEC 425C PRO.

•

Set the knob of the choice wire diameter selection

[16] in "1.0" position. Set the knob of the choice

welded material and gas mixture [17] in "CRNI

(98%AR 2%CO

2

)" position.

•

Switch the supply of the POWERTEC 425C PRO

on.

•

Within 15s switch the knob of the choice wire

diameter selection [16] in "1.2" position and the

knob of the choice welded material and gas mixture

[17] in "STEEL (100%CO

2

)" position – the water

cooler has been switched on and the display "V"

has lit "on".

If it is necessary to return the automatic work of the

water cooler you should do the foregoing actions again

(the display “V” has lit " 5'' ").

WARNING

The display "V" lights information about work mode of

the water cooler (5"/on) for 2 seconds after the supply of

the POWERTEC 425C PRO is switched on.

Welding Cables Connections

Insert the plug of the ground cable into the socket [10] or

[11]. The other end of this cable connects to the work

piece with the work clamp.

Connect the Euro connector to the welding torch with the

contact tip and torch liner suitable for the wire diameter

and material welded.

Loading the Electrode Wire

Open the side cover of the machine.

Unscrew the fastening cap of the sleeve.

Load the spool with the wire on the sleeve such that the

spool turns clockwise when the wire is fed into the wire

feeder.

Make sure that the spool locating pin goes into the fitting

hole on the spool.

Screw in the fastening cap of the sleeve.

Put on the wire roll using the correct groove

corresponding to the wire diameter.

Free the end of the wire and cut off the bent end making

sure it has no burr.

WARNING

Sharp end of the wire can hurt.

Rotate the wire spool clockwise and thread the end of

the wire into the wire feeder as far as the Euro socket.

Adjust force of pressure roll of the wire feeder properly.

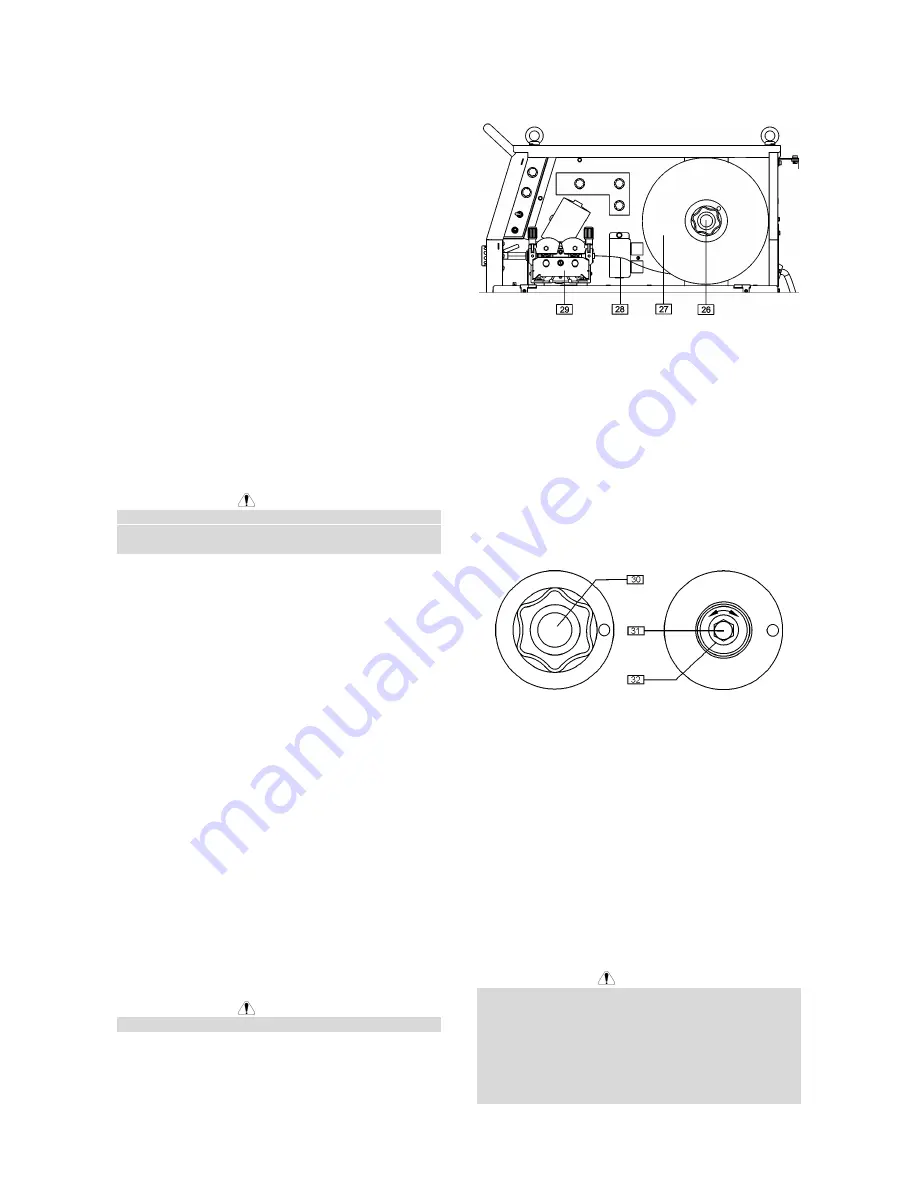

26. Sleeve.

27. Wire spool.

28. Electrode wire.

29. Feeding unit.

The machine is designed for wire spools of 15kg

(300mm).

Adjustments of Brake Torque of Sleeve

To avoid spontaneous unrolling of the welding wire the

sleeve is fitted with a brake.

Adjustment is carried by rotation of its screw M10, which

is placed inside of the sleeve frame after unscrewing the

fastening cap of the sleeve.

30. Fastening cap.

31. Adjusting screw M10.

32. Pressing spring.

Turning the screw M10 clockwise increases the spring

tension and you can increase the brake torque.

Turning the screw M10 counterclockwise decreases the

spring tension and you can decrease the brake torque.

After finishing of adjustment, you should screw in the

fastening cap again.

Adjusting of Pressure Roll Force

Pressure force is adjusted by turning the adjustment nut

clockwise to increase force, counterclockwise to

decrease force.

WARNING

If the roll pressure is too low the roll will slide on the wire.

If the roll pressure is set too high the wire may be

deformed, which will cause feeding problems in the

welding gun. The pressure force should be set properly.

Decrease the pressure force slowly until the wire just

begins to slide on the drive roll and then increase the

force slightly by turning of the adjustment nut by one

turn.