Page Number - 3

Form 402140

INSTALLATION

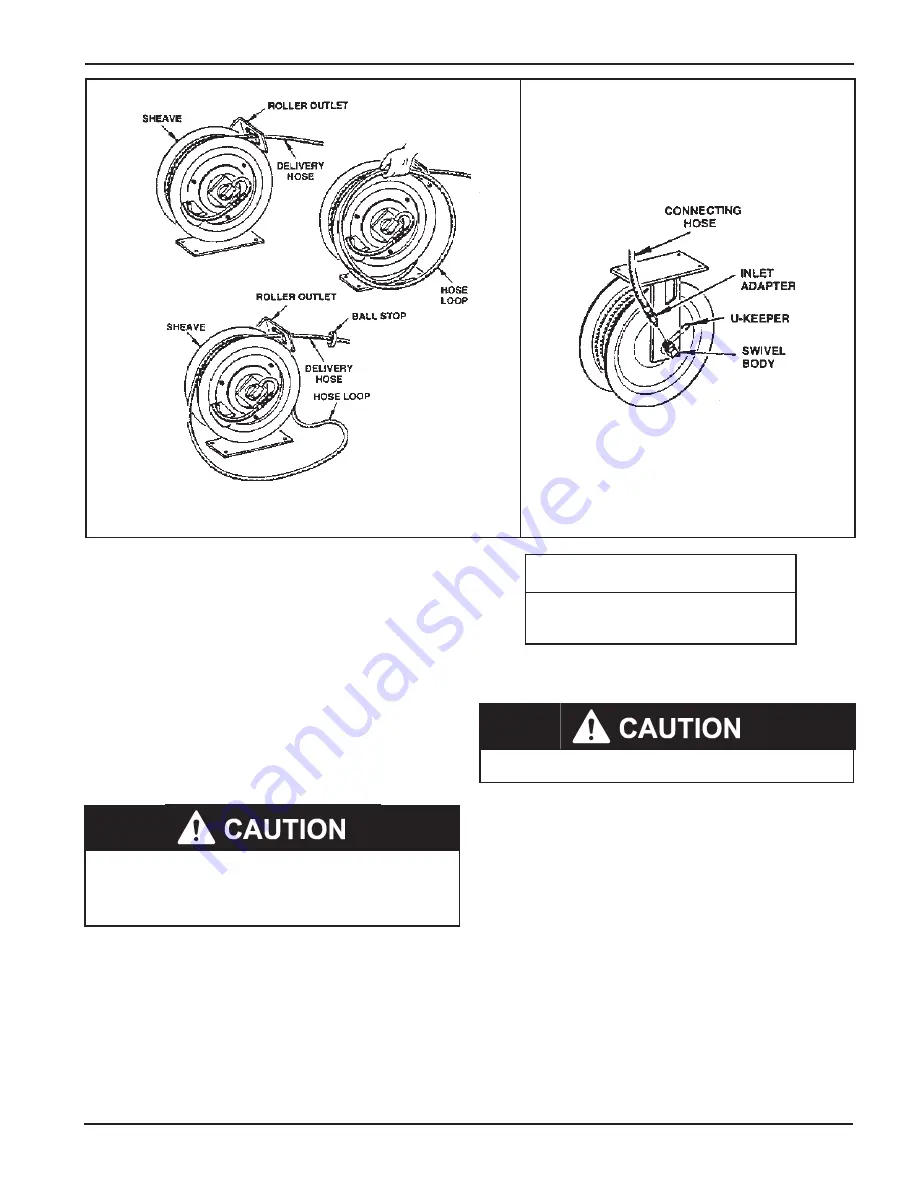

DELIVERY HOSE INSTALLATION

(MAXIMUM SPRING TENSION)

For smoother operation during retraction and to increase hose

life, “detalc” hose by wiping entire hose length with a light lubri-

cating oil before installing on reel.

Assemble outlet adapter to hose and tighten securely. Use

teflon tape on threads to prevent leaks.

See Figure (1). Insert hose end with outlet adapter through

roller outlet and secure to axle head with U-keeper. Make sure

seal is installed correctly in axle before assembling.

FIGURE (1) DELIVERY

FIGURE (2) CONNECTING

To prevent damaging hose connections and/or components

when pulling hose from reel, pull on the hose itself and not

on the control valve or swivel. Do not pull or jerk on the hose

when fully withdrawn from the reel.

From open side of reel, loop entire length of hose onto reel in

a clockwise direction. Pull hose out through roller outlet to wind

power spring. When hose is completely extended, latch reel to

prevent it from unwinding.

Continue to add loops of hose and pull out hose until power

spring winds tight.

IMPORTANT

INSTRUCTIONS

Perform the following instructions as

stated to correctly set the power spring

for maximum tension.

Allow reel to retract two full revolutions and latch reel.

Carefully unloop remaining hose from reel.

To avoid damaging reel components, always make sure

hose clamp is properly installed.

Position hose clamp so that approximalely 1/2 loop of hose

remains on reel and latching does not occur when hose is fully

extended.

While holding hose, allow reel to retract hose until desired

height from floor is obtained, then latch reel.

Slide ball stop over free end of hose and position slightly be-

low roller outlet. Tighten screws to secure ball stop to hose.

Power spring is now set to maximum tension.

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com