Page Number - 4

Form 402140

ADJUSTING SPRING TENSION

To prevent premature power spring failure, spring

tension should be adusted so that it requires at least

two full turns of the reel sheave before the spring is

wound tight.

Should less spring tension be desired, pull hose out from

roller outlet to provide slack and latch reel.

Unwind one loop of hose from reel. Pull excess hose out

through roller outlet and unlatch reel to retract hose.

Check tension and repeat above procedure until desired

tension is obtained.

ATTACHING CONNECTING HOSES

To prevent damage to connecting hose when install-

ing hose to reel, sufficient clearance must be provided

from outside edge of sheave.

See Figure (2). Remove U-keeper and inlet adapter from

swivel body.

If adapter assembly (273065) is damaged, replace at

this time.

Assemble swivel adapter to connecting hose.

Reconnect inlet adapter to swivel body and replace U-

keeper

Connect other end of connecting hose to material supply

line source or connection

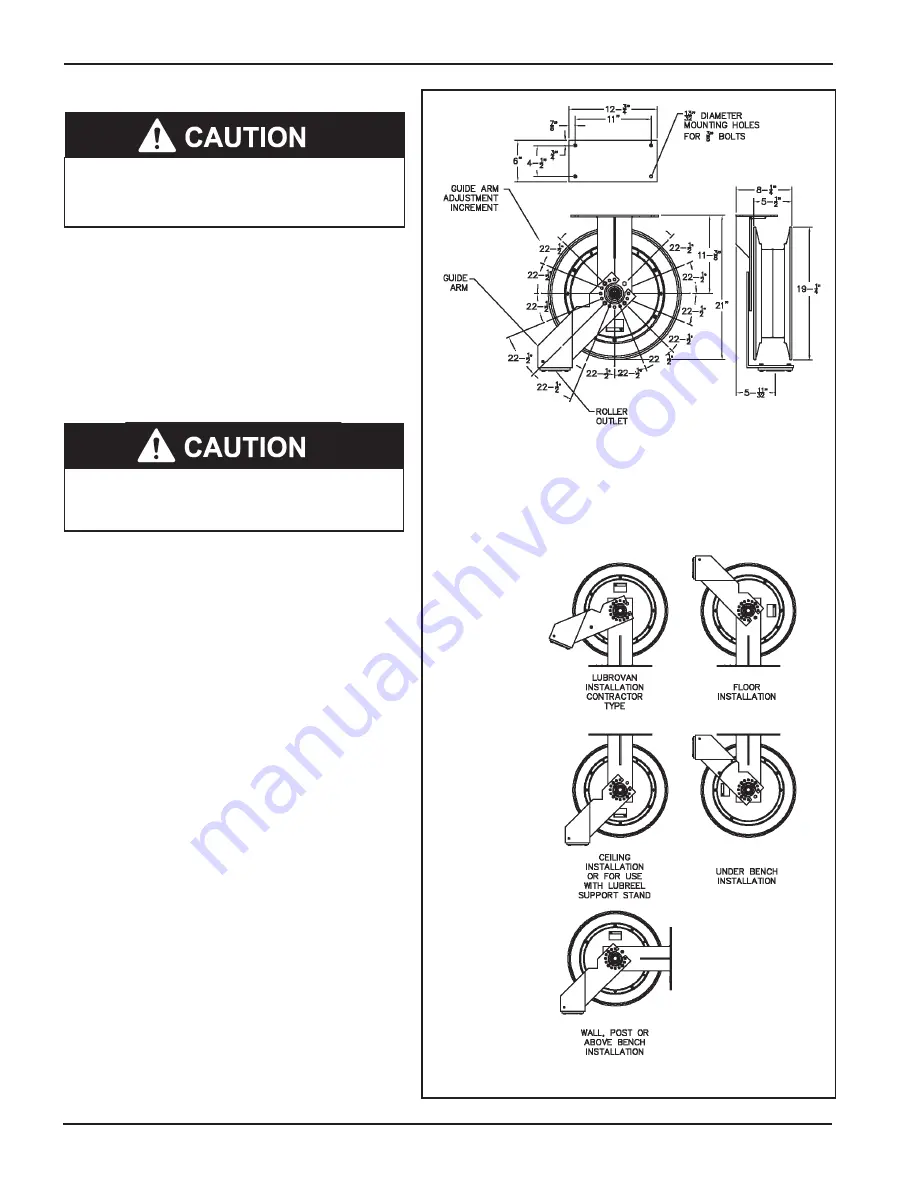

FIGURE (3) REEL INSTALLATION AND ADJUSTMENT

REEL INSTALLATION AND ADJUSTMENT

See Figure (3). The guide arm may be positioned in

22-1/2 degree increments as shown. For ease of opera-

tion and increased hose life, the guide arm should be

positioned to minimize hose strain as the delivery hose

is pulled tnrough the roller outlet.

Three studs must be used to securely attach the guide

arm. It may be necessary to change the position of the

hex head screw and one stud in order to obtain the

desired guide arm position.

The hose clamp must be relocated if the guide arm is

in position B or C. Refer to SERVICE PARTS for hose

clamp location

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com