3.3 Function

The CLK-type lubrication systems for conveyor chains generally

comprise a piston pump with electromagnetic control, an oil reser-

voir and a control unit. The lubricant is supplied to the lubrication

points by means of projection nozzles.

3.3.1 Oil projection

With these systems the lubricant is projected to the lubrication point

without any mechanical contact.

Lubrication is done while the chain is moving.

For optimal oil projection, very small amounts of oil should be pro-

jected at a specific time on the chain lubrication point. A proximity

sensor is used to accurately determine the position of the chain, the

rollers and the links, and so the exact time for projecting the lubri-

cant. When the lubrication point is detected, the control unit triggers

a lubrication pulse. At each lubrication pulse, the electromagnetic

pump releases precise lubricant doses - 60 mm3 /pulse - which are

projected toward the lubrication point.

The user sets, from the integrated control unit, the duration of the

lubrication cycle. For more information, see section 6.2 Control unit.

3.3.2 Capillarity

When the lubricant has reached the lubrication point by projection, it

penetrates between the different elements of the chain by capillarity.

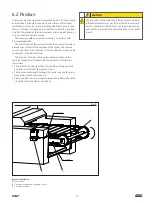

1

Fig. 4

Friction zone

1

Lubricant inlet

2

Lubricant film

3

Pin

4

Outer plate

5

Roller

6

Bearing

7

Inner plate

2

3

4

7

6

5

A lubricant film is formed at the friction zones. It reduces the tempe-

rature rising and therefore the part wear. In addition, it provides

extra protection against external pollution, by preventing the foreign

matter (dust, particles ...) to penetrate between the different parts.

Friction zones

The chains have a large number of friction zones that should be

lubricated. The example below shows a sectional view of a roller

chain with different parts and friction zones.

13

Summary of Contents for SKF CLK

Page 37: ...37 ...