6.3 Installation

During installation, and more specifically when holes should be car-

ried out, it is mandatory to observe the following points:

• During installation, do not damage the existing lines.

• During installation, do not damage the other existing groups.

• The central unit should not be mounted in the range of moving

parts.

• The central unit should be installed at a sufficient distance from

heat sources

(† Technical data)

.

• It is mandatory to observe safety distances, as well as local guide-

lines on installation and accident prevention.

• Use existing holes if possible.

• Use washers if the holes on the holder are too large.

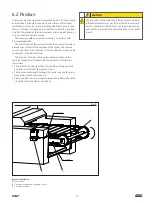

6.3.1 Installing the central unit

The central unit is intended to be mounted on a wall.

The central unit has four mounting plates, two located in the

reservoir, and two on the housing

(† fig. 6)

. The mounting plates

are intended for M8 × 1.25 Class 8.8 (metal bracket) screws or

expansion metal plugs and diameter 8 screws. Mounting is carried

out in the space provided for this purpose and with the appropriate

mounting material (e.g.. screws, washers, nuts).

It is important to provide a free space

(† fig. 7)

around the central

unit to allow all installation and maintenance works, as well as the

unit filling.

269 mm

≠

Ø 10,5

238 mm

~12 kg

~208,5 mm

Fig. 6

System installation

0,5 m min.

0,5 m min.

0,8 m min.

Fig. 7

Free space

CAUTION

It is necessary to properly secure the lubrication system on

its support to prevent any accidental system fall. A system

fall may damage it or cause material damage and can also

injure the operator or other people.

18

Summary of Contents for SKF CLK

Page 37: ...37 ...