8

/15

and verifying the correct movement of the blade and the correct

functioning of the microswitches (limit switches).

• If the damper is not connected to a remote control or command

system, manually execute an opening and closing test and check

the correct movement of the blade and the correct functioning of

the microswitches (limit switches) if present.

Together with the control activities, it is recommended to visually

verify the absence of corrosion, the integrity of the electrical wiring

and the sealing of the construction support.

Damper cleaning is included in the ordinary maintenance activities

of the ventilation ducts.

Fire dampers can be cleaned with a dry or wet cloth.

In the case of resistant dirt, it is possible to use normal household

detergents.

If prescribed for the type of building, it is possible to use disinfectant

detergents.

The use of detergents or mechanical abrasive cleaning systems is not

permitted.

These indications comply with the standards EN 15650 annex D and

EN 15423 annex C.

Repair

For safety reasons, repair activities involving fire-fighting compo-

nents must be carried out only by qualified personnel.

Only original spare parts supplied by the fire damper manufacturer

must be used.

A functional test must be performed after each repair.

.

At the end of the inspection, cleaning or repair operations, check that

the fire damper is in the normal operating position.

Keep records of all inspections, repair activities, any problems en-

countered and their resolution.

This practice, even when not mandatory, is very useful in practice.

Disposal

Disposal in case of destruction must be carried out in accordance

with national legislation. For electrical and electronic parts also refer

to EU Directive 2011/65.

INSTALLATION

The sizes shown are in mm.

It is recommended to perform a functional test before Installation to

exclude possible damage during transport and another test immedi-

ately after installation to exclude accidental damage to the product

and interference with mounting components.

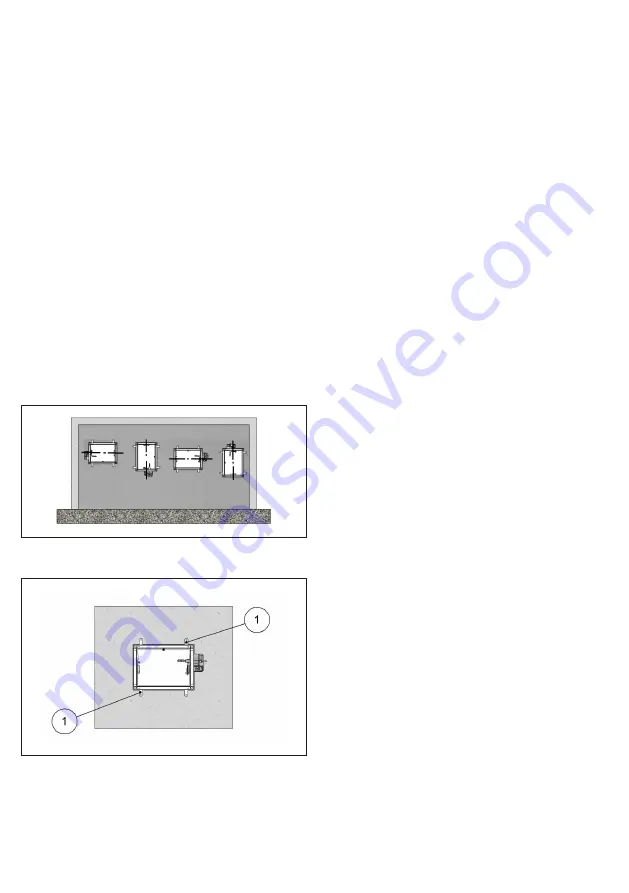

Blade rotation axis positioning

The fire damper can be installed both with the blade axis positioned

vertically or horizontally.

Positioning brackets before fixing

1. Positioning brackets

Installation of flexible connectors in order to balance out the

ventilation ducts expansion

CAUTION: Refer anyway to law and national standardization.

Flexible connectors compensate any duct thermal expansion and

wall bending in case of fire.

Flexible connectors are used to limit fire damper stresses due to ex-

ternal forces in case of fire and to preserve fire resistance class.

In general it is always appropriate the use of flexible connectors for

the followings installations:

– light walls;

– Plasterboard and rock wool or Fire Batt (Weichschott) sealing;

– Applique fixing system.

Flexible connector must be normal flammability and in case of fire

the grounding bonding should disconnet to guarantee the com-

plete separation between fire damper and connected air duct.

When flexible connectors made of conductive material (e.g. alumi-

num) are used, no additional grounding bonding is required.

Despite flexible connector installation, the fire damper must be in-

stalled in the construction support so that its weight does not affect

damper’s installation position both during normal operation and in

case of fire.

It is recommended not to compress flexible connectors in the in-

stallation phase.

Flexible connector must be at least 100mm long and in order that

possible duct thermal expansions are balanced.

Take care that the flexible connector does not interfer with opening

/ closing movement of the blade.

Transfer Application (application not connected to air ducts on

one or both sides)

Following tests performed as per EN 1366-2, section 6.3.6 Standard,

it is possible to install the fire damper free from air duct from one or

both sides.

• Attention: fire resistance classification for transfer application is

conform to section Fire resistance classification according to EN

13501-3-2009 limited to EI 120S if the ducted classification is high-

er.

• End cap with mesh shall be mounted on the side not connected

to air duct.

• End cap with mesh is made from galvanized steel sheet and in-

cludes nuts and screws for fixing on fire damper.

• End cap with mesh is supplied loose from the fire damper.