TECHnICAL DATA

FBC

1 - 4 - 7

9

/34

rev 20-02

TECHnICAL DATA

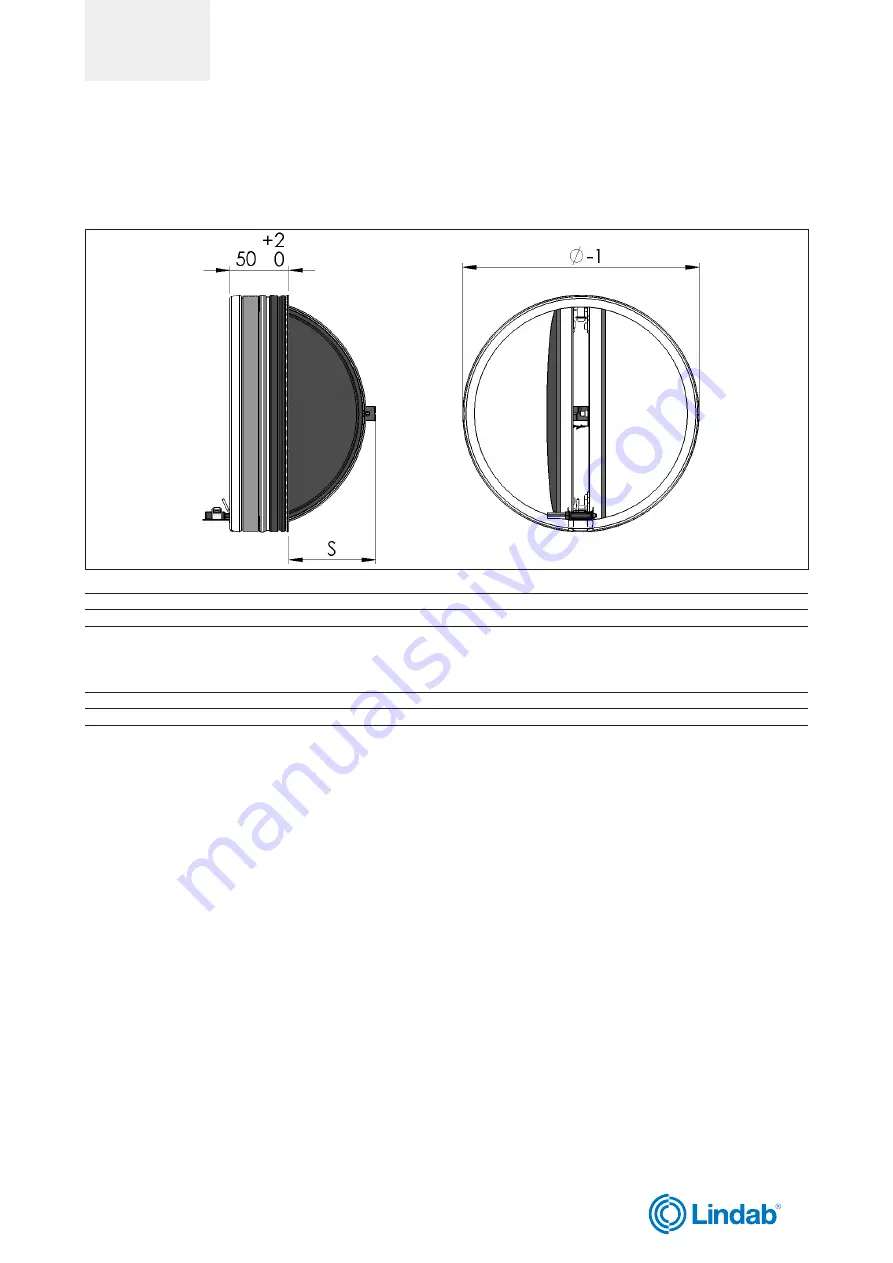

The sizes shown are in mm.

Dimension

Ø

mm

100

125

160

200

S blade exposition

mm

21

34

51

72

Weights

Ø

mm

100

125

160

200

Weight

kg

0,2

0,3

0,4

0,6

FBC

1 - 4 - 7

9

We reserve the right to make changes without prior notice