5

/14

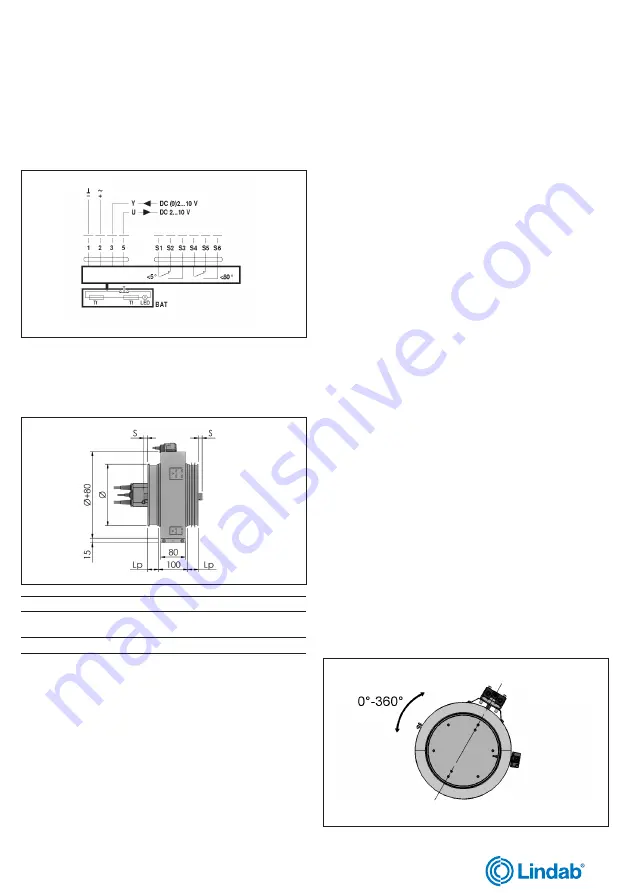

Electrical wiring for Belimo BFL24-SR-T modulating motorized version

24V AC/DC power supply

/- Negative (DC) or neutral (AC) black wire

~/+ Positive (DC) or phase (AC) red wire

3 Positioning signal Y

5 Positioning feedback U (max 0,5mA)

Microswitches position contacts

S1 Common closed damper microswitch

S2 Normally closed, closed damper microswitch

S3 Normally opened, closed damper microswitch

S4 Common open damper microswitch

S5 Normally closed, open damper microswitch

S6 Normally opened, open damper microswitch

Tf Thermal fuse

TECHNICAL DATA

The sizes shown are in mm.

Dimension

Ø

mm

100

125

160

200

250

315

400

S blade

exposition

mm

0

0

0

30

40

80

157

Lp

mm

40

40

40

40

60

60

80

Lp

Overlap length between fire damper and duct

MAINTENANCE AND

INSPEC TIONS

Fire dampers and control mechanisms do not require routine main-

tenance.

Extraordinary maintenance (repairs) and periodic inspection opera-

tions are the responsibility of the ventilation system operator.

It is recommended to keep enough space (about 200mm) for using

or replacing the control mechanism or for maintenance. Also provide

the necessary space to remove the ventilation duct from the damper

whenever necessary.

It is recommended to provide inspection hatches on both sides of

the ducts connected to the fire damper.

The implementation of a periodic inspection plan allows to guaran-

tee the efficiency and functionality of the fire dampers for the fire

safety of the building.

Periodic inspection and cleaning

Periodic inspection shall be performed in accordance with the re-

quirements of the law or by the building regulations or other local

regulations.

In the absence of specific regulations (or to their complement), in ac-

cordance with point 8.3 of the EN 1560 standard, it is recommended

to carry out the following control activities at intervals of no more

than 12 months:

• Check the servomotor electrical wiring for damage (where appli-

cable);

• Check end-switch wiring for damage (where applicable);

• Check damper cleanliness and clean where necessary;

• Check the condition of blades and seals, rectify and report where

necessary;

• Check the correct opening and closing of the fire damper by ma-

nual operation according to the instructions in the technical ma-

nual of the fire damper;

• Check the opening and closing operation of the damper control-

led by the fire alarm system (if present);

• Check the operation of the end switches in open and closed state,

adjust and report if necessary;

• Confirm that the damper fulfils its function as part of the control

system (where necessary);

• Check that the damper is left in its normal operating position, whi-

ch usually corresponds to the open position.

Repair

For safety reasons, repair activities involving fire-fighting componen-

ts must be carried out only by qualified personnel.

Only original spare parts supplied by the fire damper manufacturer

must be used.

A functional test must be performed after each repair.

.

At the end of the inspection, cleaning or repair operations, check that

the fire damper is in the normal operating position.

Keep records of all inspections, repair activities, any problems en-

countered and their resolution.

This practice, even when not mandatory, is very useful in practice.

Disposal

Disposal in case of destruction must be carried out in accordance

with national legislation. For electrical and electronic parts also refer

to EU Directive 2011/65.

INSTALLATION

The sizes shown are in mm.

It is recommended to perform a functional test before Installation to

exclude possible damage during transport and another test imme-

diately after installation to exclude accidental damage to the product

and interference with mounting components.

Blade rotation axis positioning

The fire damper can be installed with the blade axis positioned verti-

cally or horizontally or tilted at any angle.

rev 20-12

5

We reserve the right to make changes without prior notice