8

Motorized fire dampers electical wiring

To connect the dampers to the power supply, proceed as follows:

• Check that the voltage and electrical frequency are equivalent to

those of the motor of the servomotor (check the motor’s informa-

tion label);

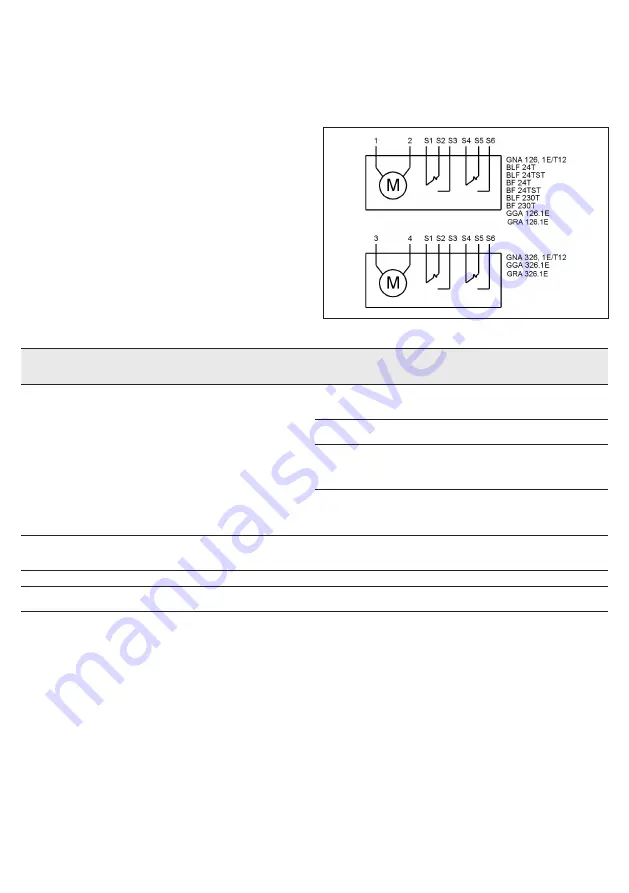

• Make the connections as shown in the below diagram.

Microswitches position for motorized version

1 Negative (DC) or neutral (AC)

2 Positive (DC) or phase (AC)

3 Phase

4 Neutral

S1 Common closed damper

microswitch

S2 Normally closed, closed damper

microswitch

S3 Normally opened, closed

damper microswitch

S4 Common open damper

microswitch

S5 Normally closed, open damper

microswitch

S6 Normally opened, open damper

microswitch

Electrical specifications

Manual and compact manual

Manual with magnet

Belimo motorized version

Siemens motorized version

Voltage and power consumption

-

Magnet (WK25MR/MI):

24/48 V DC (automatic voltage switching

on S0-25 electric board for 24V magnet)

Power interrruption magnet (MR):

P = 1,6 W

Power input magnet (MI):

P = 3,4 W

Motor 24 V AC/DC (WK25VSB):

Belimo BFL24T

Opening: 2,5 W

In stand-by: 0,8 W

Motor 230 V AC (WK25DSB):

Belimo BFL230T:

Opening: 3,5 W

In stand-by: 1,1 W

Motor 24 V AC/DC (WK25VSS):

Siemens GRA126

Opening: 3,5 W

In stand-by: 2 W

Motor 230 V AC (WK25DSS):

Siemens GRA326

Opening: 4,5 W

In stand-by: 3,5 W

Microswitches position contacts

Manual control version:

12VDC / 2A

125VAC / 0,1A

Motorized version:

Siemens: AC 24V…230V / 6 (2)A

Belimo: DC 5V…AC 250V / 1mA…3A (0,5A)

Blade closing time

Spring: 1 s

motor: < 30 s

Protection degree

IP42

IP42 MAGNETIC VERSION

IP54 MOTORIZED VERSION

MAINTENANCE AND INSPEC TIONS

The MP3 fire dampers don’t need maintenance.

Periodic inspection

The damper inspection must be done according to national law.

The periodic inspection must be according to EN 15423 annex C and

EN 15650 annex D.

When a remote control system, such as a smoke or other alarm sig-

nal, is used to close fire dampers, the correct working of such alarm

signals must be tested during the periodic maintenance and check

of the full fire safety system.

Disposal

Disposal in case of destruction must be carried out in accordance

with national legislation. For electrical and electronic parts also refer

to EU Directive 2011/65.

INSTALLATION

The sizes shown are in mm.