7

/17

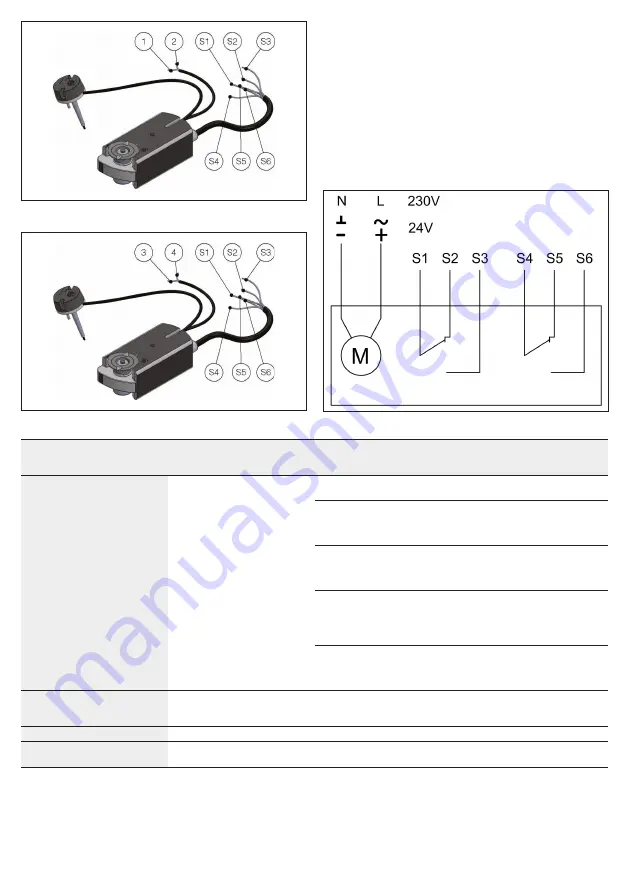

Siemens servomotor:

GRA326, GNA326, GGA326.

Motorized fire dampers electical wiring

To connect the dampers to the power supply, proceed as follows:

• Check that the voltage and electrical frequency are equivalent to

those of the motor of the servomotor (check the motor's informa-

tion label);

• Make the connections as shown in the below diagram.

1 Negative (DC) or neutral (AC)

2 Positive (DC) or phase (AC)

3 Phase

4 Neutral

S1 Common closed damper microswitch

S2 Normally closed, closed damper microswitch

S3 Normally opened, closed damper microswitch

S4 Common open damper microswitch

S5 Normally closed, open damper microswitch

S6 Normally opened, open damper microswitch

Electrical specifications

Manual

Manual with magnet

Belimo motorized version

Siemens motorized version

Voltage and power consumption

-

Power interrruption magnet:

P=4,5 W (24V DC or 230 V AC version)

Power input magnet:

P=4,5 W (24V DC or 230 V AC version)

Motor 24V AC/DC (WK45VMB):

Belimo BFN24T

Opening: 4 W

In stand-by: 1,4 W

Motor 230V AC (WK45DMB):

Belimo BFN230T

Opening: 5 W

In stand-by: 2,1 W

Motor 24V AC/DC (WK45VGB):

Belimo BF24T

Opening: 7 W

In stand-by: 2 W

Motor 230V AC (WK45DGB)

Belimo BF230T

Opening: 8 W

In stand-by: 3 W

Motor 24V AC/DC (WK45VPS) /

(WK45VSS):

Siemens GNA126 / GRA126

Opening: 3,5 W

In stand-by: 2 W

Motor 230V AC (WK45DPS) / (WK45DSS):

Siemens GNA326 / GRA326

Opening: 4,5 W

In stand-by: 3,5 W

Motor 24V AC/DC (WK45VGS):

Siemens GGA126

Opening: 6 W

In stand-by: 1.5 W

Motor 230V AC (WK45DGS):

Siemens GGA326

Opening: 6 W

In stand-by: 2,5 W

Microswitches position contacts

Manual control version:

15 - 400V

1,8 A

Motorized version:

Siemens: AC 24V…230V / 6 (2) A

Belimo: DC 5V…AC 250V / 1mA…3A (0,5A)

Blade closing time

Spring: 1 s

motor: < 30 s

Protection degree

IP42

IP42 MAGNETIC VERSION

IP54 MOTORIZED VERSION

MAINTENANCE AND INSPEC TIONS

Fire dampers and control mechanisms do not require routine main-

tenance.

Extraordinary maintenance (repairs) and periodic inspection opera-

tions are the responsibility of the ventilation system operator.