Linddana A/S

. Ølholm Bygade 70 . DK-7160 Tørring . T +45 75 80 52 00 . tp@linddana.com . www.linddana.com

Brugsanvisning: TP 230 fra dato 02.11.2015 ©Copyright 2008

17

8.3.2

Knives

The machine is equipped with three knives.

The knives must always be replaced as a set. The knives form a set and should be sharpened so

that they are always of equal width. If the knives are not the same width, the rotor will not be

balanced, which will cause unnecessary strain on the bearings and vibrations throughout the

machine.

What to do:

Stop the machine and turn off any power. Loosen the bolts holding the two sections of the rotor

housing together and open the rotor housing.

Turn the rotor until the rotor lock connects with one of the ejector blades on the rotor. The rotor

is now locked

(see Figure 14). Keep your fingers well away from the knives when turning the rotor.

Figure 14 Locking the rotor using the rotor

lock

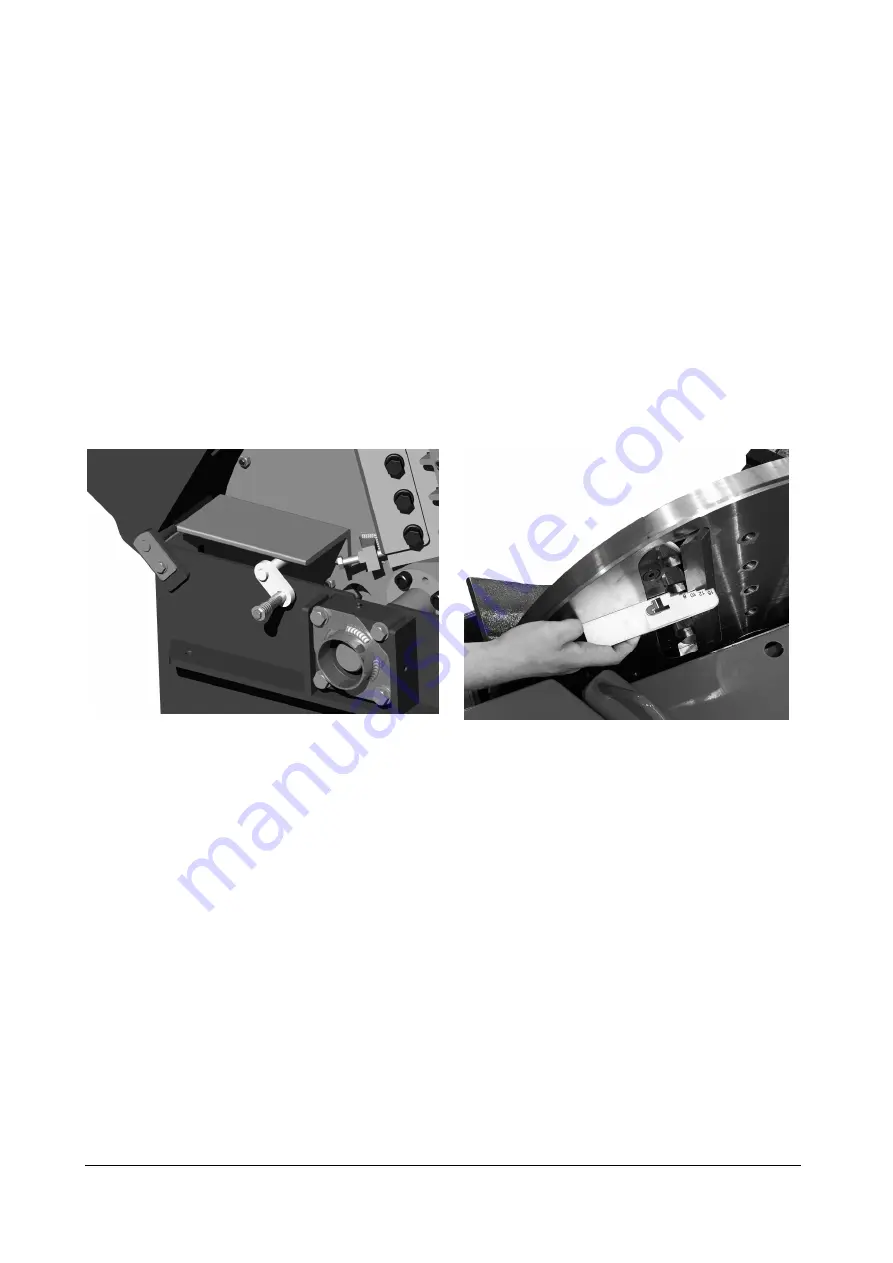

Figure 15 Knife measure

Remove the four nuts holding the knife and the clamping plate to the rotor. Remove the knife

and any sliver breaker. The contact surfaces on the cutting disc and the knife and sliver breaker

must be cleaned thoroughly before fitting knives and sliver breaker. When fitting, the nuts

must

be lightly oiled (

m

=0.125), i.e. light oil, WD 40 or equivalent. Copper grease, MoS

2

or equivalent

low-friction grease must

not

be used.

When fitting knifes the knife measure (See Figure 15) is used for correct knife distance.

Check that the gap between knife edge and anvil is correctly set to

1 mm

.

The nuts must be tightened to

200 Nm/20 KPm

. Use the wrench, included in the tool kit, for this.

This can be purchased as extra equipment.

Once the knives have been replaced, turn the rotor several revolutions to ensure there are no

objects in the rotor housing. Close the rotor housing and tighten the bolts (See Figure 12).