9

9

2

2

O

O

p

p

e

e

r

r

a

a

t

t

i

i

n

n

g

g

I

I

n

n

s

s

t

t

r

r

u

u

c

c

t

t

i

i

o

o

n

n

s

s

–

–

3

3

3

3

5

5

8

8

0

0

1

1

1

1

7

7

0

0

1

1

E

E

N

N

–

–

0

0

4

4

/

/

2

2

0

0

1

1

4

4

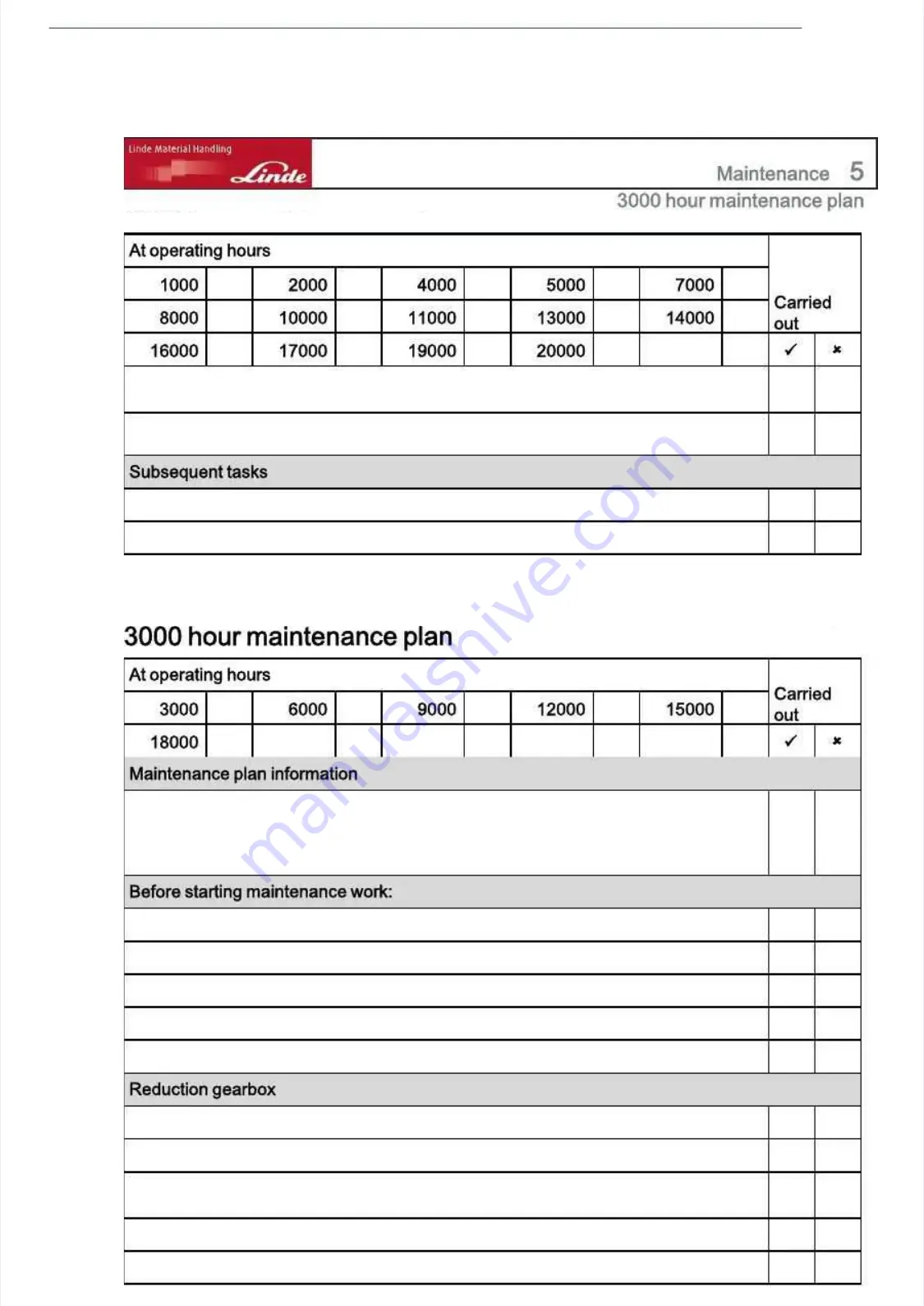

Maintenance

Maintenance

5

5

300

300

0

0

hou

hou

r

r

mai

mai

nte

nte

nan

nan

ce

ce

pla

pla

n

n

At

At ope

operat

rating

ing hou

hours

rs

11000000

22000000

44000000

55000000

77000000

88000000

1100000000

1111000000

1133000000

1144000000

Carried

Carried

out

out

1166000000

1177000000

1199000000

2200000000

Che

Check

ck tha

thatt the

the si

side

de mov

moving

ing for

forks

ks are

are ope

operat

ratin

ing

g nor

norma

mall

lly;

y; cl

clean

ean,, lub

lubri

ricat

cate

e and

and ch

check

eck

thei

theirr fast

fastenin

enings.

gs.

Chec

Check

k the pre

the pre-tig

-tighten

htening sta

ing status

tus of

of the dou

the double hos

ble hose in truck

e in trucks

s equi

equipped

pped wit

with attac

h attach-

h-

ments.

ments.

Subs

Subsequen

equentt tas

tasks

ks

Car

Carry

ry out a

out a fu

funct

nction

ional

al te

test

st an

and

d te

test

st dr

driv

ive.

e.

Attach

Attach the main

the maintenance sticker

tenance sticker..

30

3000

00 ho

hour

ur ma

main

inte

tennan

ance

ce pl

plan

an

At

At ope

operat

rating

ing hou

hours

rs

33000000

66000000

99000000

1122000000

1155000000

Carried

Carried

out

out

18000

18000

Main

Maintena

tenance

nce plan

plan info

informat

rmation

ion

Maintenanc

Maintenance intervals are set according to the

e intervals are set according to the type of oil

type of oil used, driving habits and

used, driving habits and

operating requirement

operating requirements, but maintenance should be

s, but maintenance should be carried out according to this

carried out according to this

main

maintena

tenance pl

nce plan at

an at leas

leastt ever

every 3,

y 3, 9, and 1

9, and 15 work

5 working ye

ing years. Please r

ars. Please refer

efer to the

to the oil

oil

use recommendations.

use recommendations.

Befo

Before

re star

starting

ting main

maintena

tenance

nce work

work::

Clean the fo

Clean the fork

rk lif

liftt tru

truck if

ck if nec

neces

essa

sary

ry

Ch

Chec

eck

k th

the

e ti

time

me an

and

d da

date

te se

sett

ttin

ings

gs on

on th

the

e di

disp

spla

lay

y un

unit

it;; ad

adju

just

st if

if ne

nece

cess

ssar

ary.

y.

Ch

Chec

eck

k fo

forr er

erro

rorr co

code

des

s on

on th

the

e di

diag

agno

nost

stic

ic so

soft

ftwa

ware

re an

and

d de

dele

lete

te..

Calibrate

Calibrate the

the pote

potenti

ntiomet

ometer

er and

and joy

joysti

sticks

cks..

Se

Sett a

a re

remi

minde

nderr for

for the

the nex

nextt mai

mainte

ntenan

nance

ce ch

check

eck on

on di

diagn

agnos

ostic

tic sof

softw

tware

are..

Redu

Reducti

ction

on gearb

gearbox

ox

Ch

Chec

eck

k wh

wheth

ether

er the

the sp

speed

eed red

reduct

uctio

ion

n gea

gearbo

rbox

x is

is lea

leaki

king

ng

Ch

Chec

eck

k tthe

he dri

drive

ve ax

axle

le and

and red

reduct

uctio

ion

n gea

gearbo

rbox

x fas

fasten

tenin

ings

gs

Clean both sides of the

Clean both sides of the traction motor, the power steering and working hydraulic

traction motor, the power steering and working hydraulic

pump motor

pump motor

Driv

Drive

e ax

axle

le:

: Ch

Chec

eck

k th

the

e si

side

de st

stop

ops

s an

and

d ad

adju

just

st as

as ne

nece

cess

ssar

ary.

y.

Che

Check

ck the cond

the conditi

ition of

on of the axl

the axle bearing

e bearings.

s.

https://www.forkliftpdfmanuals.com/

Summary of Contents for 335-03 Series

Page 2: ...https www forkliftpdfmanuals com...

Page 4: ...https www forkliftpdfmanuals com...

Page 9: ...1 1 Introduction Introduction https www forkliftpdfmanuals com...

Page 21: ...2 2 Safety Safety https www forkliftpdfmanuals com...

Page 43: ...4 4 Operation Operation https www forkliftpdfmanuals com...