Service Training

Section

2.6

Page

65

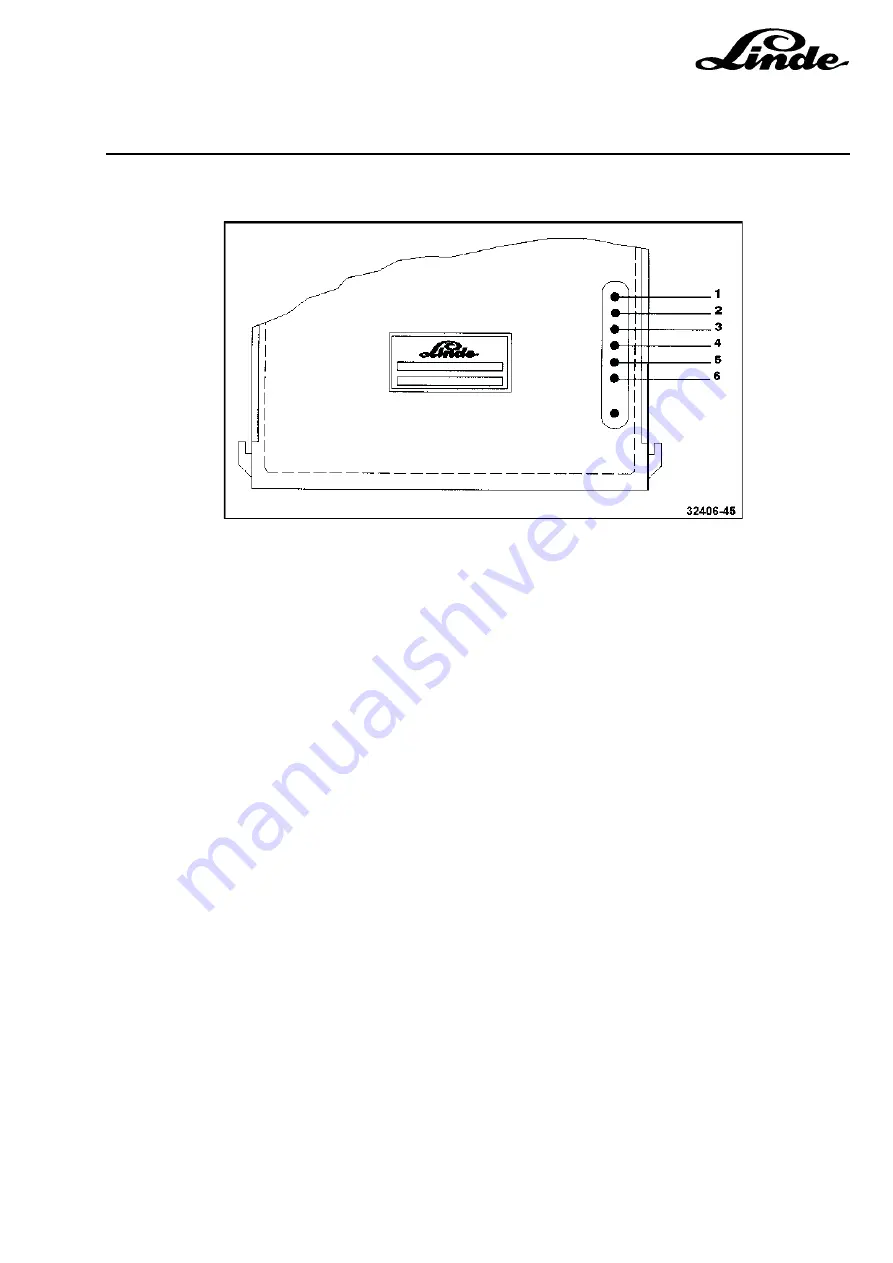

2.6.7.1.5

ADJUSTMENTS

1

Not used

2

Not used

3

Auxiliary hydraulics 1, function 1

4

Auxiliary hydraulics 2, function 2

5

Auxiliary hydraulics 2

6

Not used

LIFTING

The lifting cycle is enabled by distance sensor 2B11. The motor speed is controlled with distance sensor

2B11 on the control valve proportionally to the movement of the spool. The lifting cycle does not need to be

adjusted.

TILTING

The tilting cycle is enabled with distance sensor 2B12. The tilting cycle does not need to be adjusted.

AUXILIARY HYDRAULICS 1

The work cycle is enabled with sensor 2B13. The motor speed is set with potentiometers (3) and (4). With

potentiometer (3) it is possible to adjust the motor speed for function 1 (rotate clockwise, shift to the right,

etc.). With potentiometer (4) it is possible to adjust function 2 (rotate anti-clockwise, shifting to the left). The

setting of the motor speed depends on the type of attachment and it should be taken from the specifications

of the manufacturer of the attachment.

AUXILIARY HYDRAULICS 2

The work cycle is enabled with sensor 2B14. The motor speed is set with potentiometer (5). The setting of

the motor speed depends on the type of attachment and it should be taken from the specifications of the

manufacturer of the attachment.

NOTE:

Use a suitable screwdriver for the adjustment. All adjustments must be performed from outside

through the holes indicated by the illustration. Carry out the adjustment of the motor speed with

the right amount of force. Refit the sealing cap after completion of the adjustment.

Summary of Contents for 336 Series

Page 2: ......

Page 8: ...ServiceTraining ...

Page 12: ...ServiceTraining Section 2 1 Page 4 ...

Page 14: ...ServiceTraining Section 2 1 Page 6 2 1 4 TRACTIONMOTORDISASSEMBLY ...

Page 19: ...ServiceTraining Section 2 2 Page 3 ...

Page 21: ...ServiceTraining Section 2 2 Page 5 ...

Page 27: ...ServiceTraining Section 2 2 Page 11 ...

Page 28: ...ServiceTraining Section 2 2 Page 12 ...

Page 33: ...ServiceTraining Section 2 4 Page 1 2 4 STEERING SYSTEM ...

Page 35: ...ServiceTraining Section 2 4 Page 3 ...

Page 37: ...ServiceTraining Section 2 4 Page 5 ...

Page 39: ...ServiceTraining Section 2 4 Page 7 ...

Page 41: ...ServiceTraining Section 2 4 Page 9 ...

Page 45: ...ServiceTraining Section 2 4 Page 13 ...

Page 47: ...ServiceTraining Section 2 4 Page 15 ...

Page 53: ...ServiceTraining Section 2 5 Page 5 ...

Page 54: ...ServiceTraining Section 2 5 Page 6 ...

Page 69: ...ServiceTraining Section 2 6 Page 15 ...

Page 74: ...ServiceTraining Section 2 6 Page 20 2 6 2 3 CIRCUIT BREAKER CONTACTOR 1K6 Circuit diagram ...

Page 94: ...ServiceTraining Section 2 6 Page 40 ...

Page 111: ...ServiceTraining Section 2 6 Page 57 Connector 1X6 1 15 V 2 Output signal 3 ...

Page 126: ...ServiceTraining Section 2 6 Page 72 2 6 9 2 LOCATION OF CONNECTORS FROM SERIES 7 95 ...

Page 128: ...ServiceTraining Section 2 6 Page 74 ...

Page 145: ...Section 2 6 Page 91 ...

Page 146: ......

Page 147: ......

Page 149: ...Section 2 6 Page 93 ...

Page 150: ......

Page 153: ...ServiceTraining Section 2 7 Page 3 ...

Page 157: ...ServiceTraining Section 2 7 Page 7 ...

Page 158: ...ServiceTraining Section 2 7 Page 8 ...

Page 163: ...Section 2 9 Page 5 ...

Page 164: ......

Page 166: ...ServiceTraining Section 2 10 Page 2 ...

Page 167: ......