Service Training

Section

2.6

Page

11

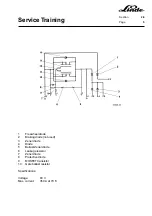

2.6.1.4

INSTALLATION OF THE POWER MODULES

The power modules used are of the MOSFET type. MOS transistors react sensitively to static discharges.

Static charges can already arise when walking over a carpet. In the worst case, the body can be charged

up to 35,000 V.

CAUTION: Before working on the power modules, the human body must be discharged by touching earth

(e.g. water pipe).

Handle the power modules carefully to prevent damage to the cooling area and to the connector.

- Clean the underside of the power module in the area of the heat sink of any dust and foreign objects.

- To reduce the heat transfer resistance between the power module and the counterweight,using a spatula,

apply a thin coating of thermal compound WPV10 to the mounting area of the power module

- Position the power module correctly.

- Tighten the M10x35 socket head screws alternately to a torque of 49 Nm.

- Insert the plug.

CAUTION: The M10x35 socket head screws must be tightened to the proper torque to ensure the correct

contact of the power module.

After 30 minutes, tighten alternate M10x35 socket head screws again.

Summary of Contents for 336 Series

Page 2: ......

Page 8: ...ServiceTraining ...

Page 12: ...ServiceTraining Section 2 1 Page 4 ...

Page 14: ...ServiceTraining Section 2 1 Page 6 2 1 4 TRACTIONMOTORDISASSEMBLY ...

Page 19: ...ServiceTraining Section 2 2 Page 3 ...

Page 21: ...ServiceTraining Section 2 2 Page 5 ...

Page 27: ...ServiceTraining Section 2 2 Page 11 ...

Page 28: ...ServiceTraining Section 2 2 Page 12 ...

Page 33: ...ServiceTraining Section 2 4 Page 1 2 4 STEERING SYSTEM ...

Page 35: ...ServiceTraining Section 2 4 Page 3 ...

Page 37: ...ServiceTraining Section 2 4 Page 5 ...

Page 39: ...ServiceTraining Section 2 4 Page 7 ...

Page 41: ...ServiceTraining Section 2 4 Page 9 ...

Page 45: ...ServiceTraining Section 2 4 Page 13 ...

Page 47: ...ServiceTraining Section 2 4 Page 15 ...

Page 53: ...ServiceTraining Section 2 5 Page 5 ...

Page 54: ...ServiceTraining Section 2 5 Page 6 ...

Page 69: ...ServiceTraining Section 2 6 Page 15 ...

Page 74: ...ServiceTraining Section 2 6 Page 20 2 6 2 3 CIRCUIT BREAKER CONTACTOR 1K6 Circuit diagram ...

Page 94: ...ServiceTraining Section 2 6 Page 40 ...

Page 111: ...ServiceTraining Section 2 6 Page 57 Connector 1X6 1 15 V 2 Output signal 3 ...

Page 126: ...ServiceTraining Section 2 6 Page 72 2 6 9 2 LOCATION OF CONNECTORS FROM SERIES 7 95 ...

Page 128: ...ServiceTraining Section 2 6 Page 74 ...

Page 145: ...Section 2 6 Page 91 ...

Page 146: ......

Page 147: ......

Page 149: ...Section 2 6 Page 93 ...

Page 150: ......

Page 153: ...ServiceTraining Section 2 7 Page 3 ...

Page 157: ...ServiceTraining Section 2 7 Page 7 ...

Page 158: ...ServiceTraining Section 2 7 Page 8 ...

Page 163: ...Section 2 9 Page 5 ...

Page 164: ......

Page 166: ...ServiceTraining Section 2 10 Page 2 ...

Page 167: ......