15/21

Linde AG, Linde Gas Deutschland ©

SETTING WELDING CURRENT AND VOLTAGE

When the wire had been installed and gas had been set it is possible to start

welding.

The appliance must be plugged into the mains, the ON/OFF switch

A1

on "I".

To select the voltage use step switch

A2.

To select the current (that is linked to the wire speed) use the potentiometer

A6 (P1)

.

WELDING MODES

Machines works in four modes:

1. Continuous two stroke (2T)

2. Continuous four stroke (4T)

3. Spot welding

4. Interval welding

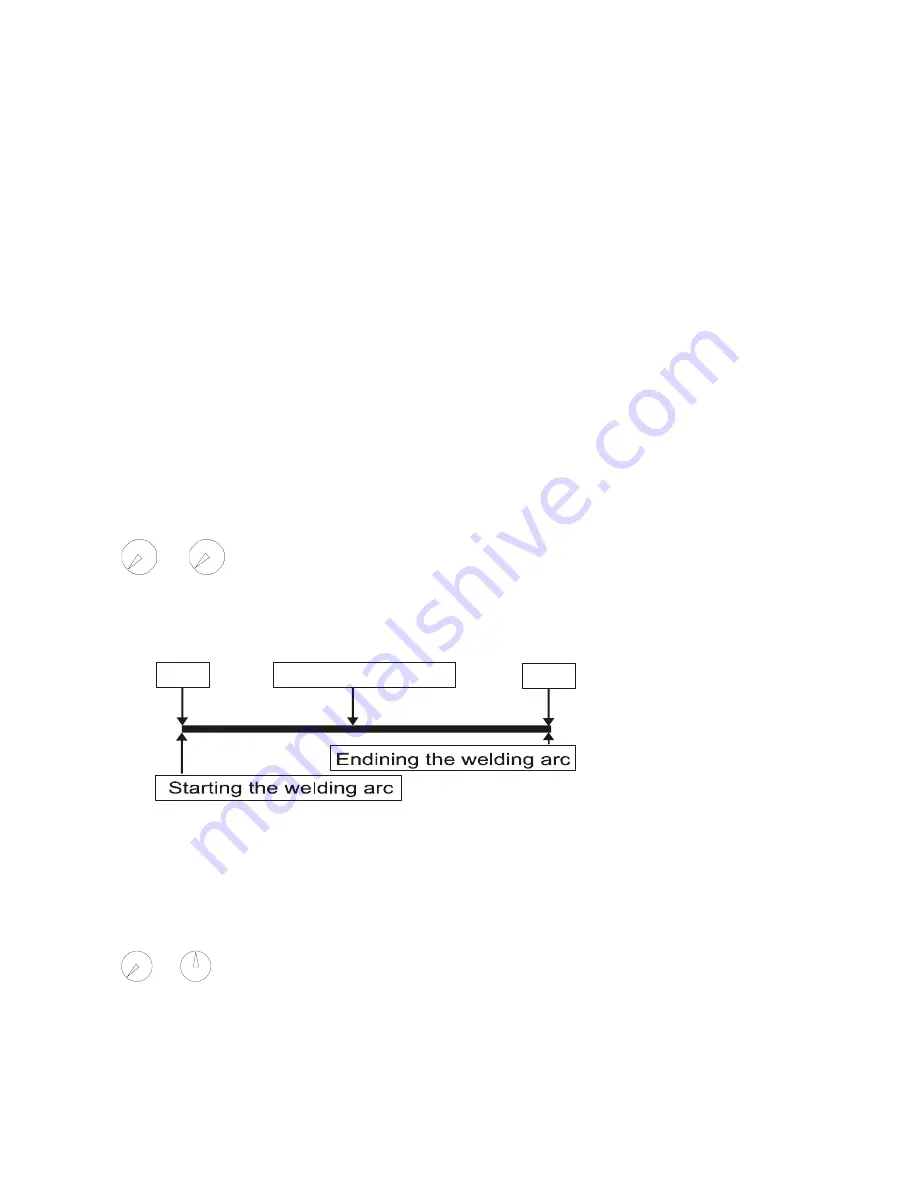

TWO STROKE

P2

P3

Both potentiometers

P2, P3

are in the OFF position. Welding

procedure starts by pressing the button in the torch handle. It is necessary to

keep the button pressed all the time during welding. The welding stops by

releasing the torch button.

1

2

Welding proces

FOUR STROKE

P2

P3

The four stroke mode is being used mostly for long welds, when

there is no need to hold the torch button pressed. The left potentiometer

P2

is in the OFF position, the right potentiometer

P3

is in the ON position. The

welding procedure start by pressing the torch button; after releasing the torch