8

11. HOW TO WORK WITH SPEED FITTINGS

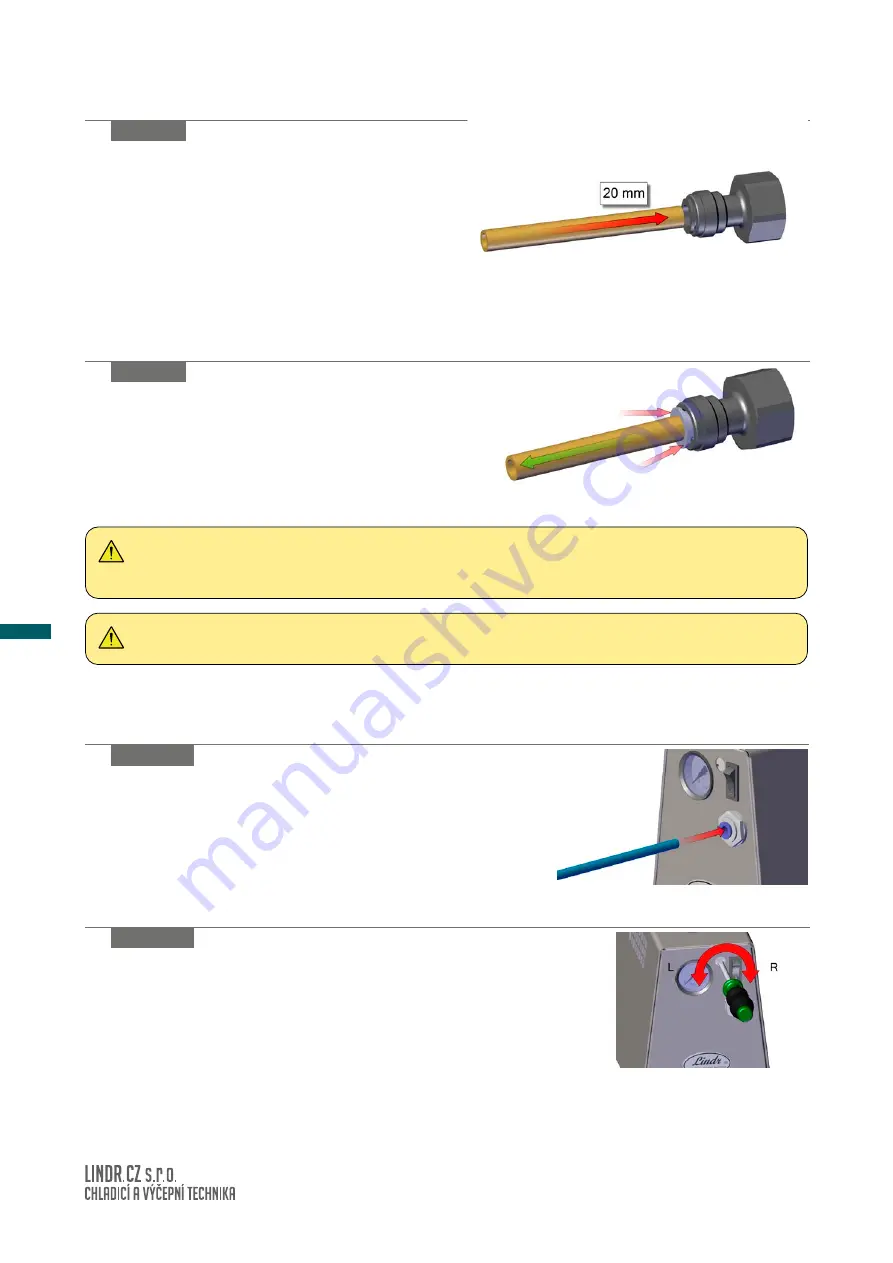

11.1 Speed Fitting Installation

Grasp the speed fitting and insert the hose all

the way inside the speed fitting body (ca. 20

mm). The end of the hose must be straight so

that it plugs fully into the coupling. If the hose

will not go in, moisten the end of the hose.

figure

8 A

11.2 Speed Fitting Removal

Hold the grey ring tight against the body of

the speed fitting and pull out the hose.

figure

8 B

WARNING:

If you do not hold the grey ring but pull at the hose, the speed fitting will cut

even deeper into the hose.

WARNING:

Hoses must not be pressurised during removal.

12. AIR CONNECTION

Connect the VK LINDR mini compressor to a keg coupler. Plug

a 5/16” air hose into the speed fitting on the front of the com-

pressor - Air outlet (1.).

13. AIR PRESSURE ADJUSTMENT

Pressure is adjusted mechanically using the adjustment screw

(3.) located on the front of the compressor. Set the pressure to

the desired value according to the pressure gauge.

figure

8 C

figure

8 D

Summary of Contents for VK 15

Page 12: ......