WARNING

Children operating or playing with a garage door

operator can injure themselves or others. The

garage door could cause serious injury or death.

Do not allow children to operate the remote

control(s) or the wall station. A moving garage

door could injure or kill someone under it. Activate

the operator only when the door is clearly visible,

free of obstructions and adjusted properly.

SEND A SIGNAL

FROM A REMOTE

THE OPERATOR'S LIGHT AND

RED LIGHT WILL FLASH ONCE IF A

REMOTE IS ADDED, THE OPERATOR'S

LIGHT AND THE RED LIGHT

WILL FLASH FOUR TIMES

IF A REMOTE IS REMOVED

1

2

ADDING OR REMOVING A REMOTE

PRESS A

BUTTON

- OR -

ENTER A CODE

AND PRESS START/STOP

PRESS THE LEARN BUTTON

FOR 10 SECONDS OR MORE

1

2

REMOVING ALL REMOTES

THE RED LIGH

AND OPERATOR’S LIGHT

T

WILL BLINK 3 TIMES

SIGNALING THAT

ALL REMOTES

WERE REMOVED

TEST WITH SMALL OBSTACLE

THE DOOR MUST REVERSE

WITHIN 2-SECONDS AFTER

IMPACT WITH A 2 x 4 BOARD

2 x 4 BOARD LAID FLAT

UNDER CENTER OF DOOR

TESTING THE SAFETY REVERSAL SYSTEM

PRESS THE

LEARN BUTTON

REMOTE MUST BE ENTERED

WHILE RED LIGHT IS ON

2

PREPARING TO ADD OR REMOVE A REMOTE

1

THE RED LIGHT WILL

GLOW FOR 15 SECONDS

SAFETY BEAM INDICATORS

RED LIGHT

GREEN LIGHT

GREEN LIGHT

ON = POWER ON

OFF = POWER OFF

RED LIGHT

ON = BEAM ALIGNED, NO OBSTRUCTION

OFF = BEAM NOT ALIGNED, OR OBSTRUCTION

BLINKING = BEAM NEEDS BETTER ALIGNMENT

ADJUSTING THE BEAM

1. ADJUST THE SENDER

AND RECEIVER UNTIL

THE RED INDICATOR

LIGHTS SOLID

2. ADJUST SENDER

UP UNTIL RECEIVER'S

RED INDICATOR FLASHES

3. ADJUST SENDER DOWN

JUST UNTIL RECEIVER'S

RED INDICATOR LIGHTS SOLID

BLOCK THE BEAM

WHILE THE TRAVELER

IS MOVING DOWN

TOWARD

DOOR

TOWARD

OPERATOR

UP

DOWN

CHECKING FOR REVERSAL

TRAVELER

THE TRAVELER MUST REVERSE

WHEN THE BEAM IS INTERRUPTED

CHECKING FORCED CLOSURE FEATURE

PLACE AN OBJECT

IN BEAM’S PATH

VERIFY THAT CONSTANT PRESSURE

ON THE WALL STATION’S OPEN/CLOSE

BUTTON WILL MAKE DOOR CLOSE

RELEASE BUTTON BEFORE OPERATOR

STOPS, THE DOORSHOULD RETURN TO

THE OPEN POSITION

WARNING

With the door closed, disengage the trolley from

the chain or belt during these alignment tests

by pulling the red release handle.

WARNING

Serious injury or death from a closing garage

door may result because of failure to test and

adjust safety reverse system. Repeat this test

monthly and adjust as needed.

4

5

6

1

2

3

USE COIN OR VISOR

CLIP IN SLOT TO

OPEN CASE

REPLACING THE REMOTE CONTROL BATTERY

CARFULLY REMOVE

THE BOARD

LIFT OFF TOP

OF CASE

REMOVE OLD

BATTERY AND

DISPOSE OF

PROPERLY

INSERT NEW

CR2032

BATTERY

PLUS SIDE UP

RE-ASSEMBLE

REMOTE CONTROL

OPERATE THE DOOR THROUGH

FOUR FULL OPEN AND CLOSE CYCLES

DOOR FORCE SETUP

4

4

WARNING

Always perform the Safety Reversal System Test

after making any adjustments to the operator.

PERFORM THE SAFETY REVERSAL SYSTEM TEST

MONTHLY!

CAUTION

Set the open and close limits carefully. Setting

the limits beyond the distance that the door

can travel could cause damage to the door, the

door hardware, or operator.

CAUTION

Do not cycle the operator full travel without

the door connected. The automatic door force

setting will adjust to the unloaded condition

and may trip the safety system when the door

is reconnected.

DOWN

UP

EXAMINE THE SPOT WHERE

DOOR CLOSES

ADJUSTING THE CLOSE LIMIT

DOWN

UP

EXAMINE THE SPOT WHERE

THE DOOR OPENS

ADJUSTING THE OPEN LIMIT

14 Adjusting the Open and Close Limits

The limit settings control how far the door will open and close. Set the limits so the door opens just short of any

door stops, and closes at the floor level.

Out of the box, the operator is preset on its close limit and the

open limit is preset for a typical 7-foot high door.

Use the wall station or a transmitter to test operate the

door. If required, use the following steps to adjust the

limits.

Adjusting the Open Limit

1. Press and hold the UP button and the LEARN button.

for approximately 3 seconds.

2. Release both buttons. When the light blinks and the

alarm beeps 2 times, the limit is ready to be set.

3. Press and hold the UP button as needed to move the

door and release the UP button when the desired

position is reached.

4. If necessary, use the UP or DOWN buttons to jog

the door at slow speed to fine-tune the open limit

position.

5. Press and release the LEARN button. The light blinks

and the alarm beeps 2 times to confirm setting.

Adjusting the Close Limit

1. Press and hold the DOWN button and LEARN button

for approximately 3 seconds.

2. Release both buttons. When the light blinks and the

alarm beeps 2 times, the limit is ready to be set.

3. Press and hold the DOWN button as needed to move

the door and release the UP button when the desired

position is reached.

4. If necessary, use the UP and DOWN buttons to jog

the door at slow speed to fine-tune the open limit

position.

5. Press and release the LEARN button. The light blinks

and the alarm beeps 2 times to confirm setting.

NOTE:

If the operator is field reset per Section 20,

both the open and close limits must be adjusted and

the automatic door force setup must be completed

for proper operation.

15 Automatic Door Force Setup

The operator automatically measures the door force throughout the entire travel of the door each time the

operator cycles. The following steps are all that’s required to setup the safety reversal system.

Automatic Door Force Setup

1

Be sure that the trolley latch is up and the door is

connected to the operator.

2

Operate the door through four complete open and

close cycles.

16 Safety Reversal System Test

The operator determines that there is an obstruction if a higher than expected amount of force is detected during

a door cycle. If an obstruction is encountered during a closing cycle, the operator and door will stop then fully

open. If an obstruction is encountered during an opening cycle, the operator and door will stop.

Safety Reversal System Test

1

Lay a 2 x 4 board flat on the floor where it will be

struck by the

center

of the door as it closes.

2

Verify that the door reverses when it strikes the

board. The door

must

reverse within two seconds

after striking the board.

17 Adjusting the Force Factor (Installation Option, Normally Not Used)

The operator uses the peak force measured during each of the last four complete cycles plus a “force factor” to

calculate the maximum allowed force setting for the current door cycle. If the calculated maximum force setting

is exceeded during the current door cycle, the operator reacts to the obstruction. As door hardware conditions

change over time with weather and wear, the calculation of the maximum door force setting using the four cycle

running average will compensate for the current conditions of the installation.

The door force is preset for the lowest amount of pressure on an obstacle to detect an obstruction. THE

FACTORY SETTING IS OPTIMIZED FOR MOST INSTALLATIONS.

Changing the Force Factor Setting

As an installation option, the operator’s “force factor” can be adjusted to change the amount of pressure exerted

on an obstacle before the operator reacts to the obstruction.

1 Press both the UP and DOWN buttons for three seconds. The red and green indicators and operator’s light will

flash twice.

2 Use the UP or DOWN buttons to set the force factor. Pressing the UP button increases the force factor, pressing

the DOWN button decreases the force factor.

FORCE FACTOR INDICATOR TABLE

GREEN ON

LOW FORCE FACTOR

RED & GREEN ON

MEDIUM FORCE FACTOR

RED ON

HIGH FORCE FACTOR

3 After selecting the force factor, press the LEARN button to store the setting and exit setup. The red and green

indicators and the operator’s light will flash two times. (If the force factor is not set within one minute, the operator

will return to normal operation at its previous force factor setting.)

4 After changing the force factor setting, perform the Safety System Reversal Test.

12 Aligning the Infrared Safety Beam

The safety beam has two components, a sender and a receiver. The sender produces a narrow infrared beam

that travels across the bottom of the door opening to the infrared receiver. If an object blocks the infrared beam

while the door is closing, the door will stop, then reverse and fully open (the operator’s light will flash three times).

As a safety feature, the operator will ignore signals from all remote controls if the door is open and the infrared

safety beam is blocked or out of alignment. In this case, the door can be forced closed by pressing and holding

the wall station’s up/down arrow pushbutton (be sure the door area is in clear view).

Safety Beam Test

1 Check that the operator has power. The green lights

on the sender and receiver should be lit.

2 If the receiver’s green light is on, but the red light is

off, the receiver has power but is not detecting the

infrared beam from the sender. The red light might

flash when the beam is partially detected. This can

be caused by mis-alignment or something blocking

the beam. Adjust the safety beam sender and receiver

while watching the receiver’s red light (stay out of the

beam while aligning it). When the red light stays on,

rotate the sender towards the ceiling and stop when

the red light on the receiver begins to flicker. Rotate

the sender back towards a horizontal position with the

floor and stop as soon as the red light on the receiver

lights solid. The beam is now properly aligned.

SAFETY BEAM INDICATOR TABLE

GREEN ON

POWER ON

GREEN OFF

POWER OFF

RED ON

BEAM OK - NO BLOCKAGE

RED OFF

BEAM BLOCKED OR MIS-ALIGNED

RED FLASHING

BEAM ALIGNED POORLY

NOTE:

If the receiver’s red light remains off, check

for: 1) Dirt on the receiver’s lens, 2) Sunlight shining

into the receiver’s lens, 3) A short in the safety beam

wiring (from staples or at the operator terminals).

3 With the door closed and the operator disengaged

from the door, press the wall station’s UP/DOWN

ARROW button to move the traveler (the part on the

belt or chain that the trolley engages with) to the up

position (away from the door).

NOTE: Do not cycle the

operator to full travel without the door connected.

4

Push the wall station’s UP/DOWN ARROW button again.

While the traveler is moving to the down position (toward

the door), block the safety beam.

THE TRAVELER MUST

STOP, THEN REVERSE TO THE UP POSITION.

The

operator’s light and red light should flash three times.

5 Place an object in the path of the safety beam.

Check that constant pressure is required on the

wall station’s UP/DOWN ARROW button to cause the

traveler to move toward the down position. Release

the pushbutton

before

the operator stops; check that

the traveler returns to the up position.

NOTE:

The garage door operator will not respond

to a CLOSE command from a radio transmitter if the

safety beam is blocked.

6

To reconnect the operator, flip the release lever up.

Raise the door manually until the operator reconnects.

NOTE:

If the door remains idle for 5 minutes, the

beam light will turn off to save power. The beam

power turns on for 5 minutes when door moves down

to the fully closed position. The beam power can be

restored for 5 minutes by pressing the light button.

13 Remote Controls

The operator is supplied with a three-button remote control (the second and third buttons can be used to control

an additional operators). Additional single and multi-button remote controls can be purchased. The short wire

on the back of the operator serves as an antenna for the remote controls. Do not cut off the wire or the remote

controls will not operate well.

To Add or Remove a Remote Control

1

Press the opener’s LEARN button until the opener’s

RED LED flashes once and the light turns on.

A

remote must be added or removed while the light

is still on (15 seconds).

2 Press and hold the desired button on the remote. The

opener’s light and the RED LED will flash once if a

remote was added.

3 Repeat Steps 1 & 2 for any additional remote controls.

To Remove A Remote Control

1

If a remote is already programmed to the opener and

you want to delete it, follow the same procedure as

ADDING REMOTES above. The opener will recognize

the remote and delete it from memory. The RED LED

and LIGHT will blink 4 times to show the REMOTE

was successfully deleted.

To Remove All Remote Controls

1

Press and hold the operator’s LEARN button for

ten (10) seconds or more, then release the LEARN

button.

2 The RED LED and the operator’s light will flash 4

times indicating ALL remotes have been remove

from memory.

Testing The Remote

1

Before testing the remote control, straighten out the

operator’s antenna wire so it points up.

2

Stand clear of the door,

press the remote control’s

button and verify that the operator starts.

PRESS

THE REMOTE CONTROL’S BUTTON AGAIN TO STOP

THE DOOR MID-TRAVEL.

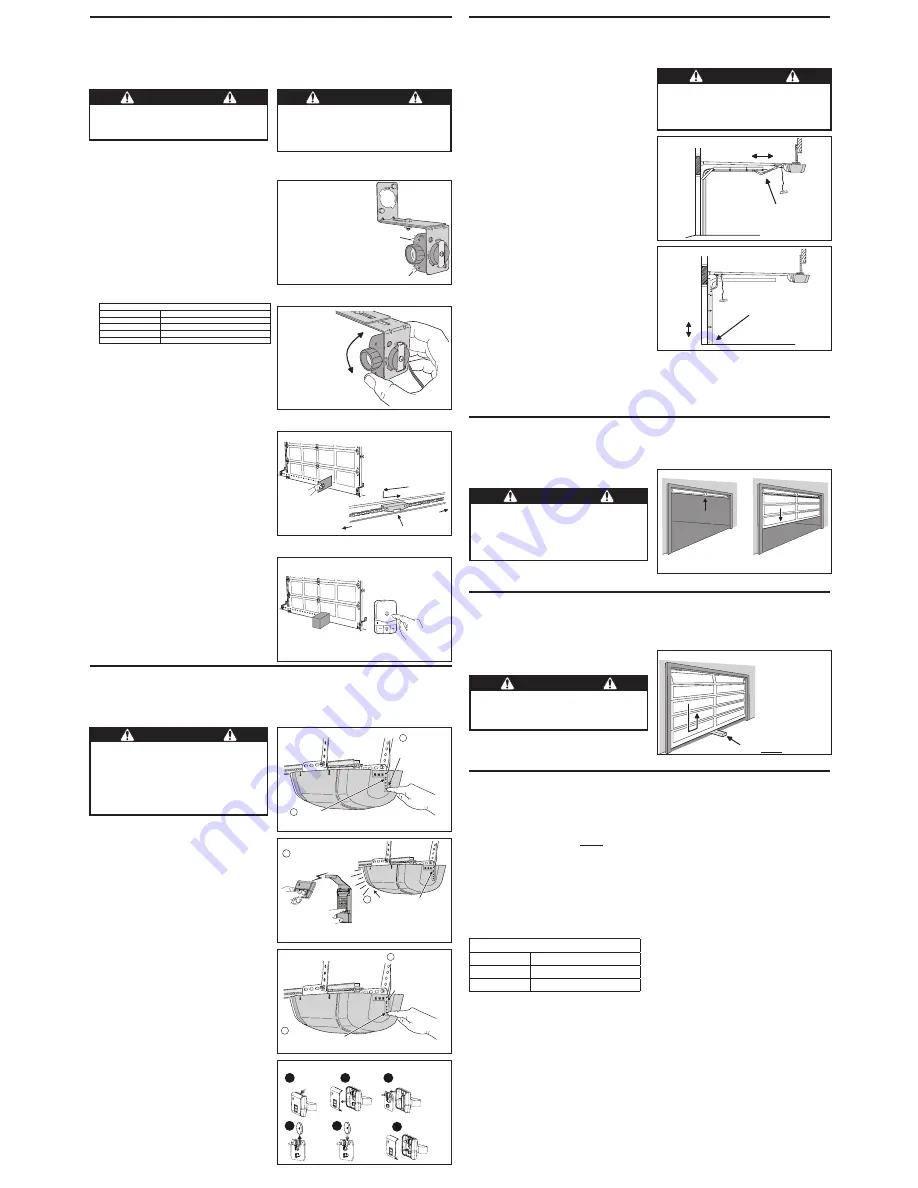

Replacing a Remote Control’s Battery

When the red light on the remote glows dimly, or fails

to light at all when the remote is activated, the battery

needs replacing.

1

Open the remote’s case and remove the circuit board.

2 Replace old battery with a Type CR2032 battery.

3 Re-assemble the remote.