VS-GSWG Swing Gate Operator Installation Guide

- 2 -

P1250 Revision X6 7-8-2011

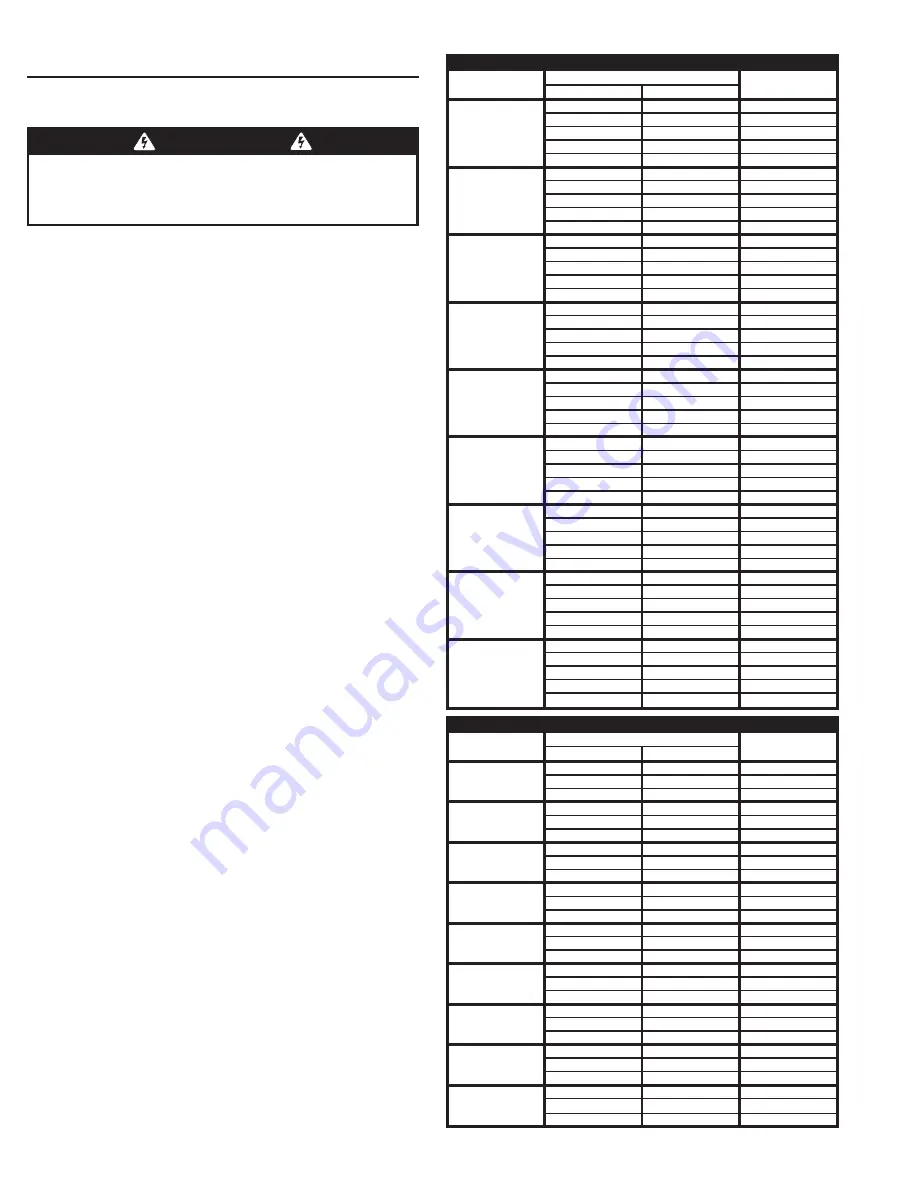

Wiring Specifi cations

Refer to the following steps for details on power and

accessory wiring for the operator.

AC Power Wiring

1. Find the listing on this page corresponding to the model, voltage and

horsepower rating of your operator.

2. The distance shown in the table is measured in feet from the

operator to the power source.

DO NOT EXCEED THE MAXIMUM

DISTANCE.

These calculations have been based on standard 115 V

and 230 V supplies with a 10% drop allowable. If your supply is under

the standard rating, the runs listed may be longer than what your

application will handle, and you should not run wire too near the

maximum distance for the gauge of wire you are using.

3. When large-gauge wire is used, a separate junction box (not

supplied) may be needed for the operator power connection.

4. Wire length calculations are based on the National Electrical Code,

Article 430 and have been carefully determined based on motor

inrush, brake solenoids, and operator requirements.

5. Connect power in accordance with local codes.

The green ground

wire must be properly connected.

6. Wire insulation must be suitable to the application.

7. Electrical outlets are supplied in all 115 VAC models for convenience

with occasional use or low power consumption devices only. If

you choose to run dedicated equipment from these devices, it will

decrease the distance for maximum length and the charts will no

longer be accurate.

DC Control and Accessory Wiring

1. All control devices are now 24 VDC, which can be run up to 2000

feet with 14 AWG wire.

2. Control wiring must be run in a separate conduit from power wiring.

Running them together may cause interference and faulty signals in

some accessories.

3. A three-wire shielded conductor cable is required to connect two

operators together for dual operation. You must use Belden 8760

Twisted Pair Shielded Cable (or equivalent) only – P/N 2500-1982,

per foot). See Page 21 for details of this connection.

Note: The shield

wire should be connected in both the operators.

WARNING

ALL AC ELECTRICAL CONNECTIONS TO THE POWER SOURCE AND

THE OPERATOR MUST BE MADE BY A LICENSED ELECTRICIAN

AND MUST OBSERVE ALL NATIONAL AND LOCAL ELECTRICAL

CODES.

USE COPPER WIRE ONLY!

MODEL VS-GSWG SINGLE PHASE POWER WIRING

VOLTS & HP

MAXIMUM DISTANCE (FEET)

WIRE GAUGE

SINGLE

DUAL

115 VOLTS

1/2-HP

222

111

12

354

177

10

566

283

8

900

450

6

1430

715

4

115 VOLTS

3/4-HP

178

89

12

282

141

10

450

255

8

716

358

6

1140

570

4

115 VOLTS

1-HP

160

80

12

254

127

10

406

203

8

646

323

6

1026

513

4

208 VOLTS

1/2-HP

760

380

12

1200

600

10

1924

962

8

3060

1830

6

4864

2432

4

208 VOLTS

3/4-HP

604

302

12

958

478

10

1526

763

8

2424

1212

6

3856

1928

4

208 VOLTS

1-HP

544

272

12

864

432

10

1374

686

8

2184

1092

6

3476

1738

4

230 VOLTS

1/2-HP

894

447

12

1422

711

10

2264

1132

8

3600

1800

6

5724

2862

4

230 VOLTS

3/4-HP

710

355

12

1128

564

10

1796

898

8

2852

1426

6

4538

2269

4

230 VOLTS

1-HP

640

320

12

1016

508

10

1616

808

8

2570

1285

6

4090

2045

4

MODEL VS-GSWG THREE PHASE POWER WIRING

VOLTS & HP

MAXIMUM DISTANCE (FEET)

WIRE GAUGE

SINGLE

DUAL

208 VOLTS

1/2-HP

1142

571

12

1816

908

10

2890

1445

8

208 VOLTS

3/4-HP

920

460

12

1464

732

10

2330

1165

8

208 VOLTS

1-HP

714

357

12

1136

568

10

1804

902

8

230 VOLTS

1/2-HP

1344

672

12

2137

1069

10

3400

1700

8

230 VOLTS

3/4-HP

1084

542

12

1723

862

10

2741

1371

8

230 VOLTS

1-HP

840

420

12

1336

668

10

2124

1062

8

460 VOLTS

1/2-HP

3841

1921

12

6106

3053

10

9712

4856

8

460 VOLTS

3/4-HP

3279

1640

12

5212

2606

10

8291

4146

8

460 VOLTS

1-HP

2689

1345

12

4274

2437

10

6798

3399

8