CHAPTER 3 ENGINE

M750L SERVICE MANUAL 18.0

CHAPTER 3 ENGINE PAGE 3-

81

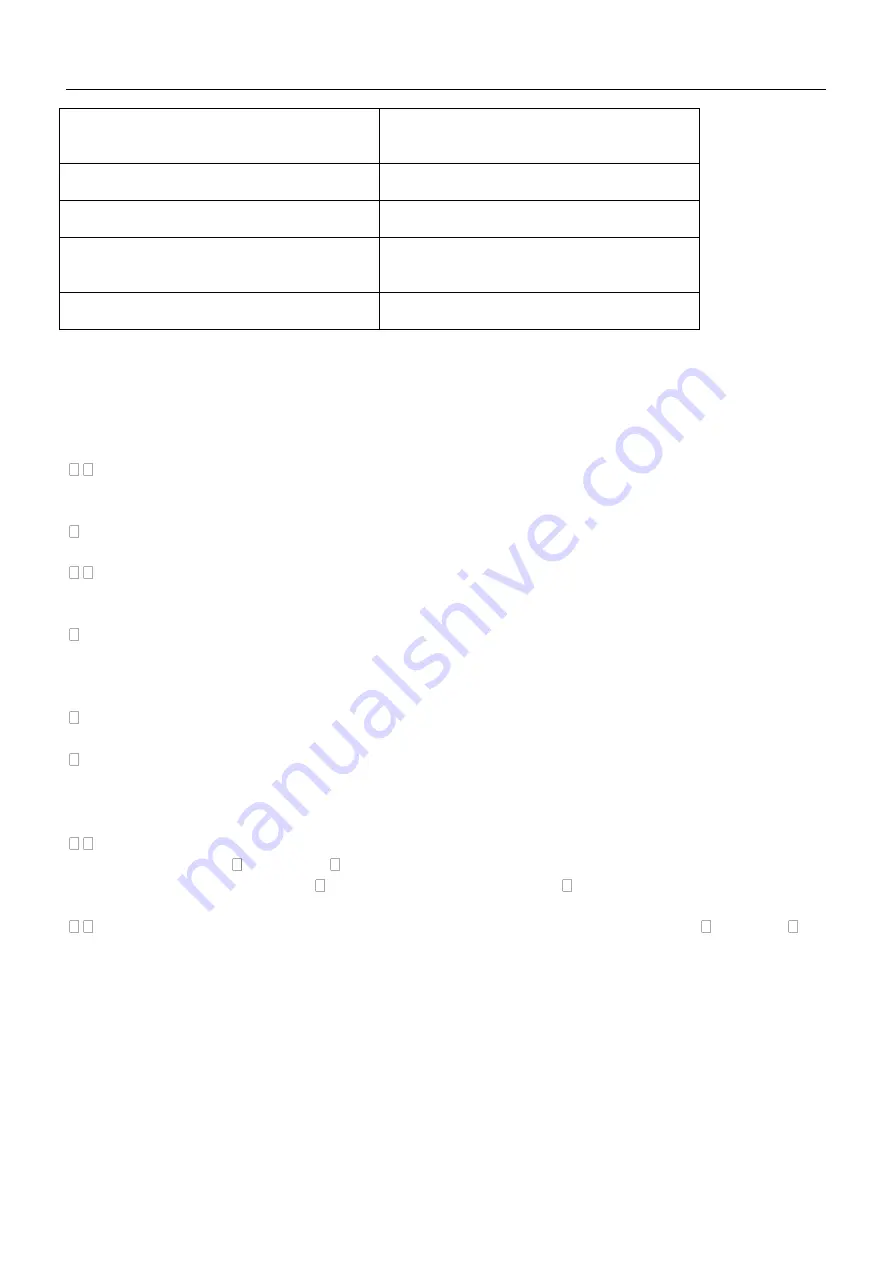

DO NOT

: Allow mud or other debris to

accumulate on the surface of the ECU

Having mud or debris accumulated on the

ECU casing reduces its heat dissipation

efficiency.

DO NOT

: Apply any voltage relative to any

point to the ECU

Drastically affects the performance of the

ECU and may lead to ECU damage

DO NOT

: Clean ECU with any solvent or

any corrosive liquid

Can damage the housing of the ECU

DO:

Take extreme care that water droplets

or excess moisture should not fall on ECU

connectors

ECU connectors can get short and may

lead to ECU damage

DO:

Clean the ECU with a moist cloth and

keep it dry

Prevents ECU damage

3.18.1 .4

Installation requirements

The ECU shall be mounted using M5 machined screws with a torque of 3.9Nm ±10%. The

mounting surface should also be flat to avoid subjecting the base plate to unnecessary force

and warping the PCB.

3.18.1 .5

Power Requirements

Power Supply: The controller’s power supply module will power up the

microprocessor if the battery voltage is greater than 6.3 Volts. The power on is

controlled by the controller hardware only.

Operating Range: All planned functions are executed in this range. Battery

and/or Ignition voltage: 9.0 to 16V DC

Power Off: The controller will turn its power off when the ignition voltage: < 6.2

V DC. The controller prepares for entry into Power Down mode. The

preparation involves storing important information into EEPROM.

Reset: During reset, all outputs shall be set to a predefined state. The

controller shall monitor itself for proper operation and enter reset should any

internal errors be detected. The controller shall then restart normal operations

after the computer has properly reset

Over Voltage: the controller will survive no permanent damage if the ignition

voltage do not exceed 26V for more than 1 minute

Reverse Voltage: The controller will survive with no permanent damage: Battery

and/or Ignition voltage < -13V DC for 1 minute

3.18.1 .6

Temperature Requirements

Storage: The controller shall suffer no damage as a result of being stored at

temperatures of -40 C or +105 C continuously for 168 hours. If the storage temperature is

not as extremely high as +105 C or as extremely low as -40 C, the ECU could be stored for

longer time without damage.

Operating: The controller shall operate in the ambient temperature from -20 C to +85 C.

3.18.1 .7

Maintenance service and Repair

ECU is a non-service

able part. Once there are problems, it’s important to first

determine if the problem is caused by software/calibration. If it is caused by

software/calibration, please refer to software/calibration reflashing procedure. In the event of

ECU hardware failure or malfunction (during warranty period only) the ECU should be sent back

to the vehicle manufacturer giving complete details of the ECU Part No, Serial number, Vehicle

Model & Make, manufacturing Date, Total kms run on the vehicle, Location of use, Vehicle No,

Date of return.

Summary of Contents for HY740STL 2018

Page 2: ...M750L ATV SERVICE MANUAL 18 0 M750L 18 0...

Page 11: ...CHAPTER 1 GENERALINFORMATION M750L SERVICE MANUAL 18 0 CHAPTER 1 GENERAL PAGE 1 6...

Page 13: ...CHAPTER 1 GENERALINFORMATION M750L SERVICE MANUAL 18 0 CHAPTER 1 GENERAL PAGE 1 8 NOTES...

Page 31: ...CHAPTER 2 MAINTENANCE M750L SERVICE MANUA 18 0 CHAPTER 2 MAINTENANCE PAGE 2 18 NOTES...

Page 93: ...CHAPTER 3 ENGINE M750L SERVICE MANUAL 18 0 CHAPTER 3 ENGINE PAGE 3 62 3 13SHIFT SYSTEM...

Page 144: ...CHAPTER 4A CHASSIS M750L SERVICE MANUAL 18 0 CHAPTER 4 CHASSIS PAGE 4 6 NOTES...

Page 168: ...CHAPTER 5 FINAL DRIVE LH500ATV D SERVICE MANUAL 14 0 CHAPTER 5 FINAL DRIVE 5 24 NOTES...

Page 182: ...CHAPTER 6 BRAKES M750L SERVICE MANUAL 18 0 CHAPTER 6 BRAKES PAGE 6 14 NOTES...

Page 184: ...CHAPTER 7 ELECTRICAL M750L SERVICE MANUAL 18 0 CHAPTER 10 ELECTRICAL 10 2...

Page 189: ...CHAPTER 7 ELECTRICAL M750L SERVICE MANUAL 18 0 CHAPTER 10 ELECTRICAL 10 7 LH700ATV EFI MODEL...

Page 209: ...CHAPTER 8 ELECTRICAL M550 SERVICE MANUAL 16 0 CHAPTER 7 ELECTRICAL CTRICAL PAGE 8 27...