CHAPTER 3 ENGINE

M565Li T3 EFI SERVICE MANUAL 20.0

CHAPTER 3 ENGINE PAGE. 3-

107

Electrical wiring to the injector should be routed so that conductors are

protected from

excessive heat, damage, and wear.

Avoid unnecessary handling

(disconnecting and connecting) of the electrical

connector.

3.5.2.9

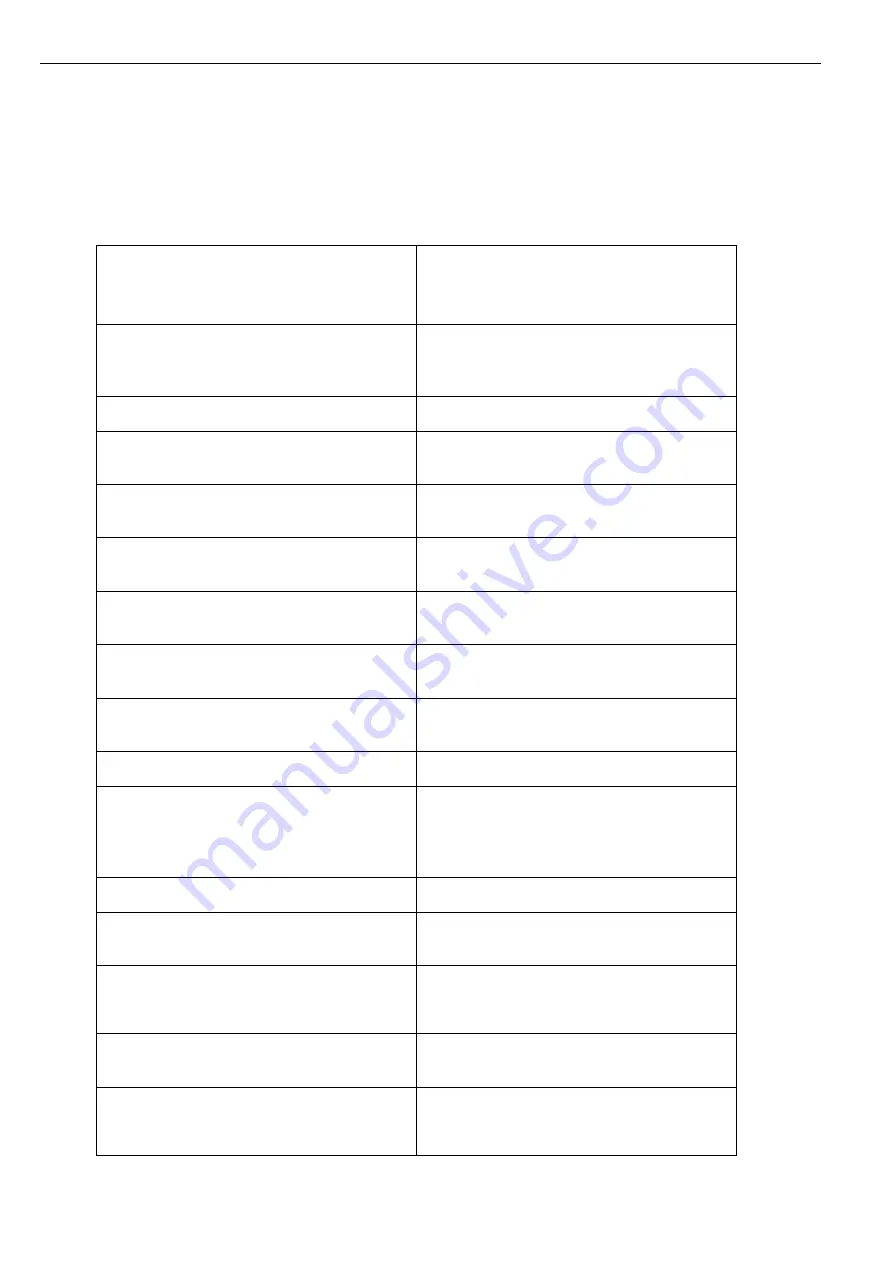

Handling - DOs & DONTs

ACTION

REASON

DO NOT

: Re-use injector seal rings if at all

possible. If no other choice exists, take extra

care in inspecting the seal rings for damage.

Leakage.

DO NOT

: Dip injector tips into lubricants.

Can plug injector spray orifices.

DO NOT

: Cycle injector repeatedly without fuel

pressure.

Damage to internal mechanical components.

DO NOT

: Pulse (actuate) a suspected high leak

rate injector (leak >50 sccm air)

Can dislodge internal contamination if

DO NOT

: Allow water to enter fuel system from

air lines, etc. during leak checks.

Can damage injectors.

DO NOT

: Contact or apply load to the injector

tip for installation.

Apply load to 45 deg angle on nylon over mold

see

DO NOT

: Pound injectors into manifold during

assembly to engine.

Can damage injectors or seal rings.

DO NOT

: Apply excessive side loads to

electrical connectors.

May cause loss of electrical continuity.

DO NOT

: Use any dropped unit.

Internal damage may have occurred.

DO NOT

: Store injectors, rails, or

subassemblies including engines on which the

injectors have been installed in an unprotected

environment.

External contamination can damage the injector

electrically and/or mechanically.

DO NOT

: Use the injector as a handle.

Do not use the injector to lift assemblies

DO NOT

: Rack, stage, or handle parts in a

manner that allows contact between parts.

Damage will occur.

DO NOT

: Remove packing in a way that allows

contact between parts.

Damage could occur due to contact

between parts

DO NOT

: Tap on fuel injectors to correct any

malfunction..

Can damage injector.

DO NOT:

Replace the injector with other part

number not recommended for this

Will severely affect the performance of the

injector

Summary of Contents for M565Li T3 EFI

Page 2: ...ATV SERVICE MANUAL EUROPE 20 0 PN F010106A27 M565Li T3 EFI 20 0 F010106A27...

Page 33: ...CHAPTER 2 MAINTENANCE M565LiT3 EFI SERVICE MANUA 20 0 CHAPTER 2 MAINTENANCE PAGE 2 20 NOTES...

Page 34: ...CHAPTER 2 MAINTENANCE M565LiT3 EFI SERVICE MANUA 20 0 CHAPTER 2 MAINTENANCE PAGE 2 21...

Page 36: ...CHAPTER 3 ENGINE M565Li T3 EFI SERVICE MANUAL 20 0 3 1 Service information...

Page 51: ...CHAPTER 3 ENGINE M565Li T3 EFI SERVICE MANUAL 20 0 CHAPTER 3 ENGINE PAGE 3 14...

Page 65: ...CHAPTER 3 ENGINE M565Li T3 EFI SERVICE MANUAL 20 0...

Page 147: ...76 CHAPTER 3 ENGINE M565Li T3 EFI SERVICE MANUAL 20 0 CHAPTER 3 ENGINE PAGE 3...

Page 186: ...CHAPTER 3 ENGINE M565Li T3 EFI SERVICE MANUAL 20 0 CHAPTER 3 ENGINE PAGE 3 115...

Page 188: ...CHAPTER 3 ENGINE M565Li T3 EFI SERVICE MANUAL 20 0...

Page 203: ...CHAPTER 3 ENGINE M565Li T3 EFI SERVICE MANUAL 20 0 CHAPTER 3 ENGINE PAGE 3 104...

Page 210: ...CHAPTER 3 ENGINE M565Li T3 EFI SERVICE MANUAL 20 0...

Page 254: ...CHAPTER 4 CHASSIS M565Li T3 EFI SERVICE MANUAL 20 0 CHAPTER 4 CHASSIS PAGE 4 6 NOTES...

Page 290: ...CHAPTER 5 FINAL DRIVE LH500ATV D SERVICE MANUAL 14 0 CHAPTER 5 FINAL DRIVE 5 36 NOTES...

Page 304: ...CHAPTER 6 BRAKES M565Li T3 EFI SERVICE MANUAL 20 0 CHAPTER 6 BRAKES PAGE 6 14 NOTES...

Page 331: ...CHAPTER 8 ELECTRICAL M550 SERVICE MANUAL 16 0 CHAPTER 7 ELECTRICAL PAGE 7 27 Switch table...

Page 337: ...CHAPTER 8 ELECTRICAL M550 SERVICE MANUAL 16 0 CHAPTER 7 ELECTRICAL PAGE 7 33 7 13 WIRING DIAGR...

Page 338: ...CHAPTER 8 ELECTRICAL M550 SERVICE MANUAL 16 0 CHAPTER 7 ELECTRICAL CTRICAL PAGE 8 34...