April 27, 2004 Manual Version 1.01

3.1

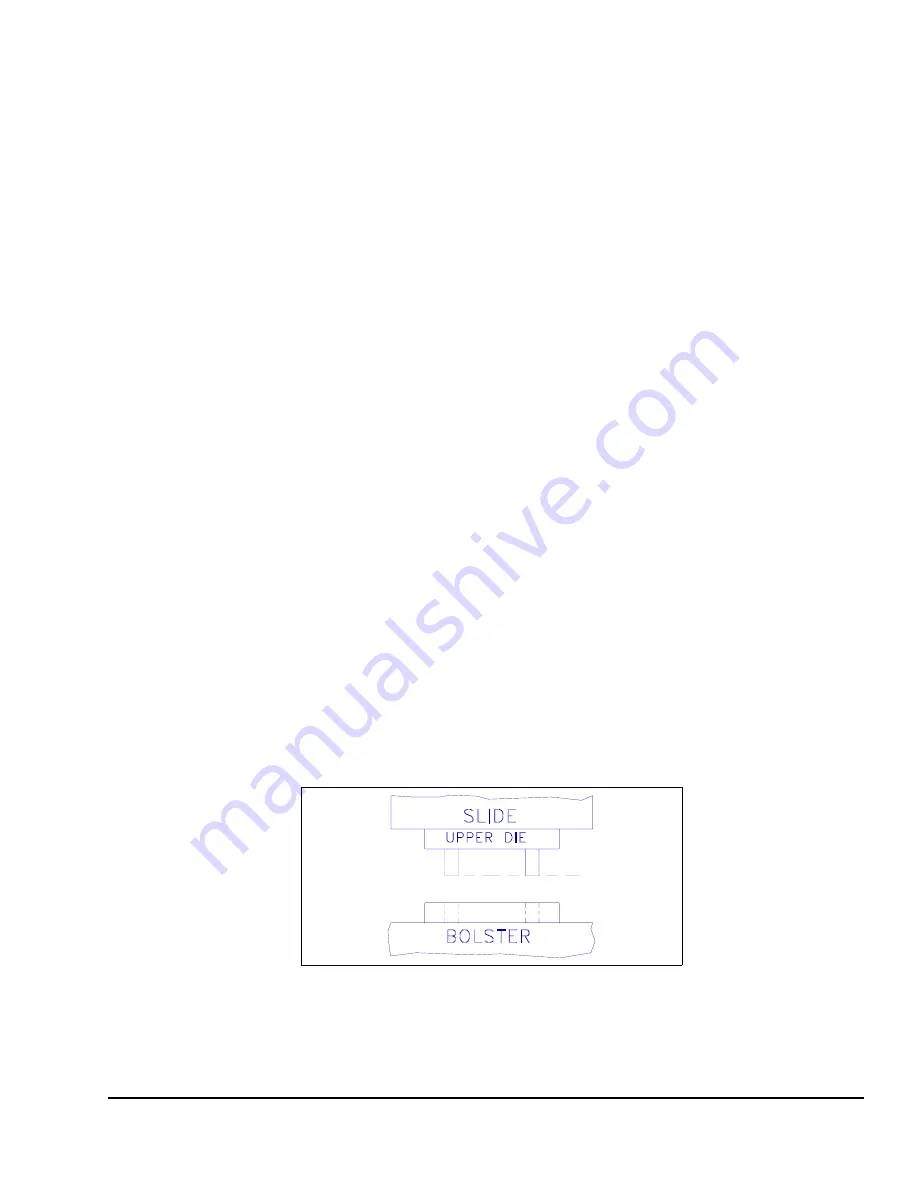

Figure 3.1:

Example Die 1

Section 3

Definitions and Terminology

This section will give some background and explain the meaning of various settings and readings in the

tonnage monitor. It is strongly recommended that this section be read in order to use the tonnage

monitor effectively!

Section 3.1

Tonnage

The tonnage monitor reads forming forces (“tonnage”) from strain gauges mounted on the machine

frame. Each strain gauge is a “channel”. Tonnage monitors typically have two or four strain gauges

depending on the type of machine. For example, OBI presses typically use two strain gauges (one on

each side), while straight side presses typically use four strain gauges (one on each corner). Section 7

covers gauge mounting considerations and procedures.

Section 3.1.1 Channel Tonnage

A channel tonnage is the tonnage read from a single strain gauge. A numerical channel tonnage reading

shown by the tonnage monitor is the highest tonnage exerted on that channel through the stroke or data

window (data windows are discussed in section 3.2). In addition, the tonnage monitor can show the

tonnage waveform for a channel. This waveform shows how the tonnage varies with press crankshaft

angle.

Section 3.1.2 Total Tonnage

In addition to recording the maximum tonnage measured for each channel, the tonnage monitor module

calculates and records the instantaneous summation of all channels. It performs the same peak

measurement on this value as is performed on the individual channels. This value is displayed as the

total tonnage exerted on the machine frame at any single position in the stroke.

When forces occur on all channels at the same time, the maximum total tonnage is the summation of the

maximum channel tonnages. For example, the die shown in Figure 3.1 contains two equally sharp

punches of equal cross-sectional area and equal length.

This die is located in the center of an OBI press bed equipped with a two channel tonnage monitor with

strain gauges mounted on both sides of the press frame. If the tonnage required for each punch is 100

tons and both punches impact the material at the same position in the stroke (at the same time) the graph

Summary of Contents for OmniLink II

Page 5: ...April 27 2004 Manual Version 1 01 iv ...

Page 7: ...April 27 2004 Manual Version 1 01 1 2 ...

Page 21: ...April 27 2004 Manual Version 1 01 3 8 ...

Page 44: ...April 27 2004 Manual Version 1 01 4 23 Section 4 5 4 N A ...

Page 45: ...April 27 2004 Manual Version 1 01 4 24 ...

Page 69: ...April 27 2004 Manual Version 1 01 7 14 ...

Page 77: ...April 27 2004 Manual Version 1 01 8 8 ...