April 27, 2004 Manual Version 1.01

7.5

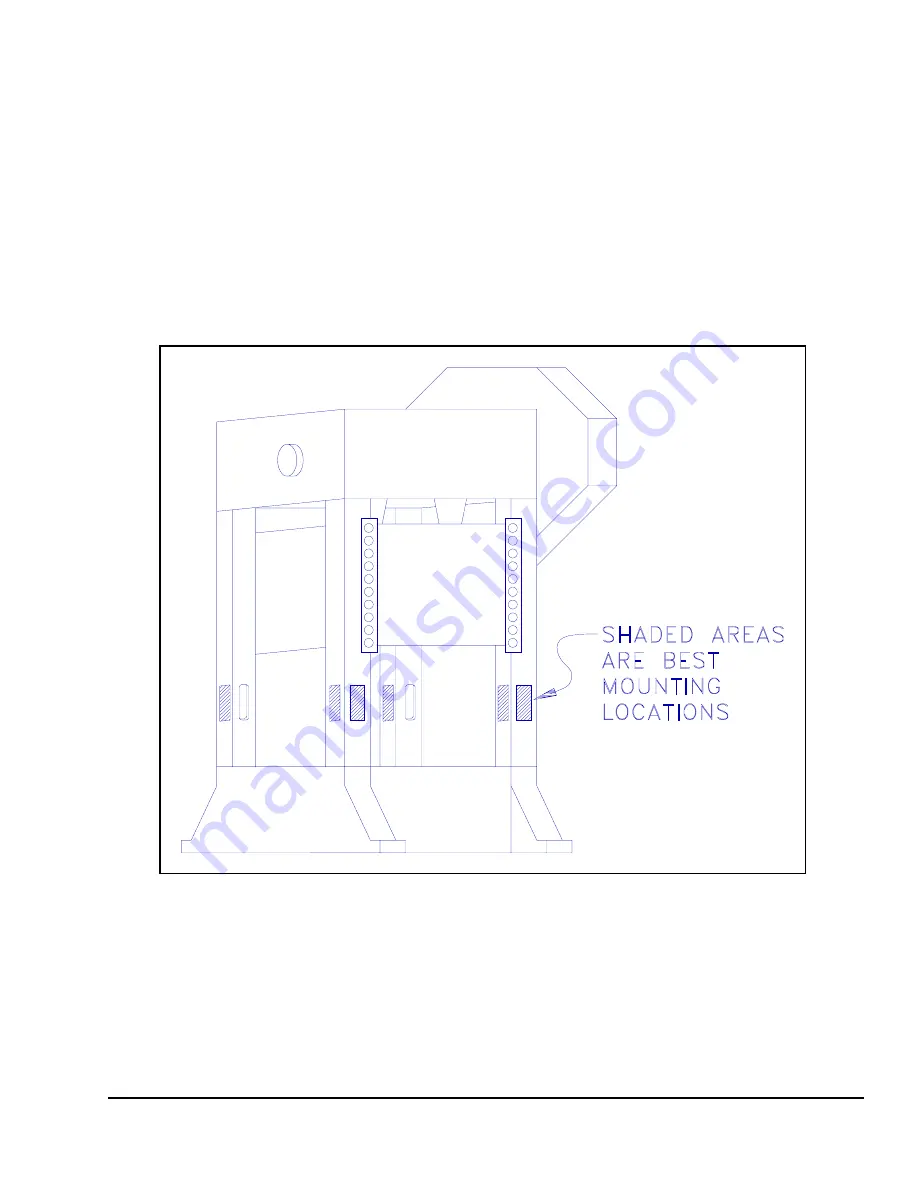

although ease of installation usually dictates mounting the strain gauges on the uprights. On solid frame

straight side machines, the uprights are also the best strain gauge locations.

The best strain gauge locations are below gibs and at least 12 inches above where the upright joins the

machine bed. Locating the strain gauge in the gib region can cause excessive bending moments to be

translated through the gibs into the upright as the slide tries to "cock" for some conditions of eccentric

loading. Locations too near the bottom of the upright may produce a nonuniform strain field. Do not

mount strain gauges on any side of an upright that has a tie rod access opening. When holes are present

in the desired upright mounting location, avoid mounting strain gauges any closer than three diameters of

the hole directly above or below the hole or any closer than one diameter of the hole to the side of the

hole. Don't mount strain gauges in recessed panel areas in uprights.

Figure 7.3:

Straight Side Machine

Stay away from corners of uprights as strain gauge mounting locations. The best locations on the upright

for strain gauges on machines of tie rod construction are generally on the centerline of the tie rod. Avoid

any mounting locations where uprights have internal reinforcements or other change of section. Insofar

as possible, strain gauges should be mounted in conditions of geometric symmetry on uprights and at the

same vertical height on each upright. Figure 7.3 illustrates mounting locations for straight side machines

of tie rod construction.

Summary of Contents for OmniLink II

Page 5: ...April 27 2004 Manual Version 1 01 iv ...

Page 7: ...April 27 2004 Manual Version 1 01 1 2 ...

Page 21: ...April 27 2004 Manual Version 1 01 3 8 ...

Page 44: ...April 27 2004 Manual Version 1 01 4 23 Section 4 5 4 N A ...

Page 45: ...April 27 2004 Manual Version 1 01 4 24 ...

Page 69: ...April 27 2004 Manual Version 1 01 7 14 ...

Page 77: ...April 27 2004 Manual Version 1 01 8 8 ...