April 27, 2004 Manual Version 1.01

7.8

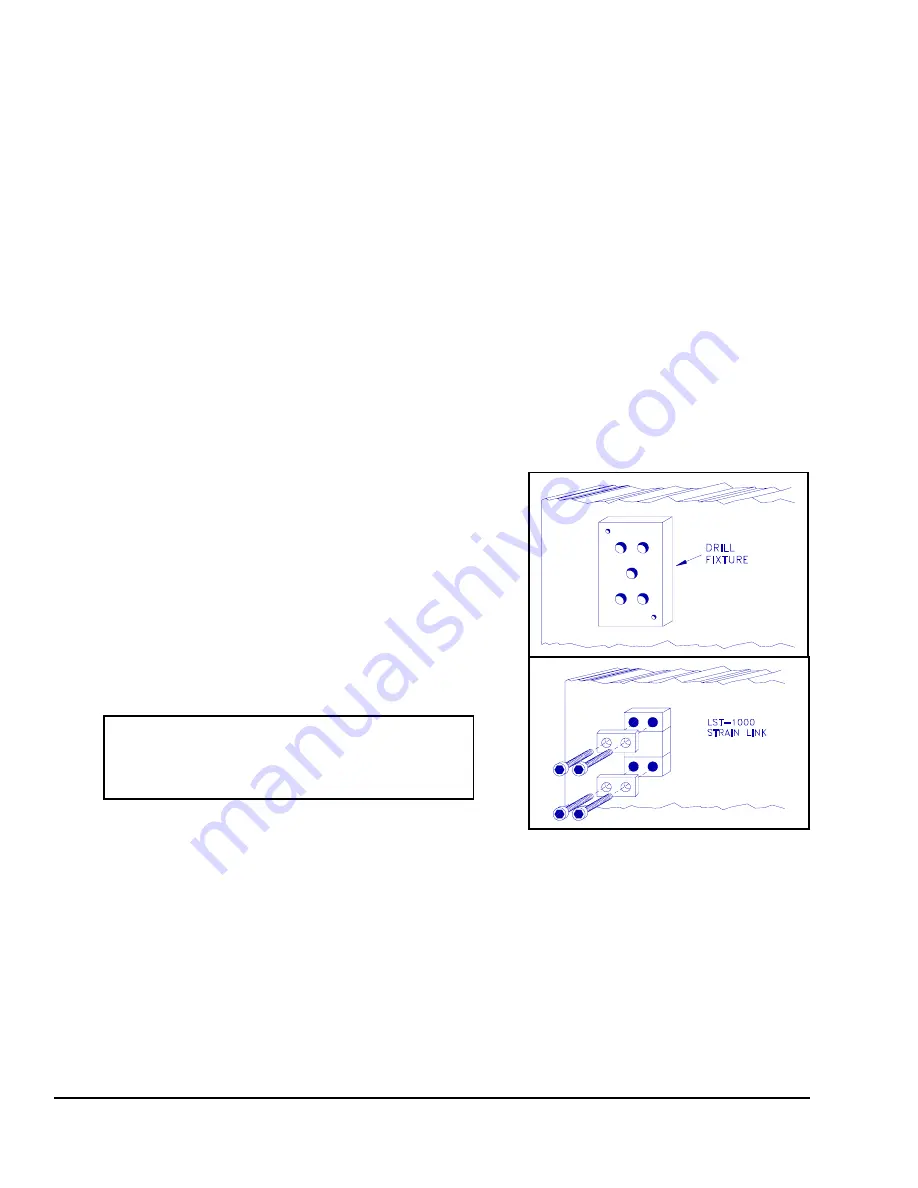

Figure 7.6:

Drill

Fixture

Figure 7.7:

LST-1000 Strain Link

Note!

Do not attempt to locate and drill

mounting holes without using the drill fixture.

The hole pattern must be precise.

Section 7.3

Strain Gauge Mounting

Strain gauges may be bolted directly to the machine or bolted to intermediate pads welded or adhered to

the machine.

Section 7.3.1 Direct Machine Mounting

1)

Select the desired mounting locations for the strain gauges.

2)

Remove paint, oil, grease, etc., to obtain a bare metal surface slightly larger than the LST-1000

strain gauge. The metal surface must be flat and smooth so that the strain gauge is not warped and

contacts the surface area evenly when mounted. A mounting surface that is flat to within .0025

inches and with a 250 microinch or less finish will give best results. Grind the surface if

necessary.

3)

Scribe a line on the metal surface on which the strain gauge is to be mounted in the direction of

tension or compression of the structural member. This will be a vertical line on columns or tie

rods of straight side presses and "C" frame machines that are not inclined. On inclined presses,

the scribe marks should follow the inclined angle.

4)

Place the hardened drill fixture provided with the direct

mounting strain gauge kit in position adjacent to the

scribed line and use a no. 3 drill to drill a 5/8" deep hold

through the center hole position of the drill fixture. Tap

the hole for a 1/4 x 28 thread. Bolt the drill fixture

securely to the mounting area, as shown in Figure 7.6.

5)

Use a no. 3 drill to drill 5/8" deep holes in the mounting

surface through the remaining four holes in the drill

fixture. Tap the holes for a 1/4 x 28 thread after

removing the drill fixture.

6)

Deburr the mounting holes and wipe the mounting area

with a clean rag.

7)

Mount the strain gauge as shown in Figure 7.7. Make

certain that the washers provided with the strain gauge kit are placed over the strain gauges.

Torque the 1/4 x 28 bolts to 150 in-lbs. A calibrated torque wrench is the preferred tool to torque

the bolts.

8)

Mount the protective cover box provided in the strain gauge kit, if used, centrally over the strain

gauge. It is important to mount the cover box before calibration begins. The cover box mounting

holes may slightly change the strain sensed by the strain gauge.

Summary of Contents for OmniLink II

Page 5: ...April 27 2004 Manual Version 1 01 iv ...

Page 7: ...April 27 2004 Manual Version 1 01 1 2 ...

Page 21: ...April 27 2004 Manual Version 1 01 3 8 ...

Page 44: ...April 27 2004 Manual Version 1 01 4 23 Section 4 5 4 N A ...

Page 45: ...April 27 2004 Manual Version 1 01 4 24 ...

Page 69: ...April 27 2004 Manual Version 1 01 7 14 ...

Page 77: ...April 27 2004 Manual Version 1 01 8 8 ...