Adjustment Step 2

Adjust the Force

Too much force on the door will interfere with

the proper operation of the safety reverse

system.

The door might not reverse properly

when required and could seriously injure or

kill someone under it. Do not increase the

force beyond the minimum amount required to

close the door. Do not use the force

adjustments to compensate for a binding or

sticking garage door. Test the safety reverse

system following all adjustments to force

levels. See page 26.

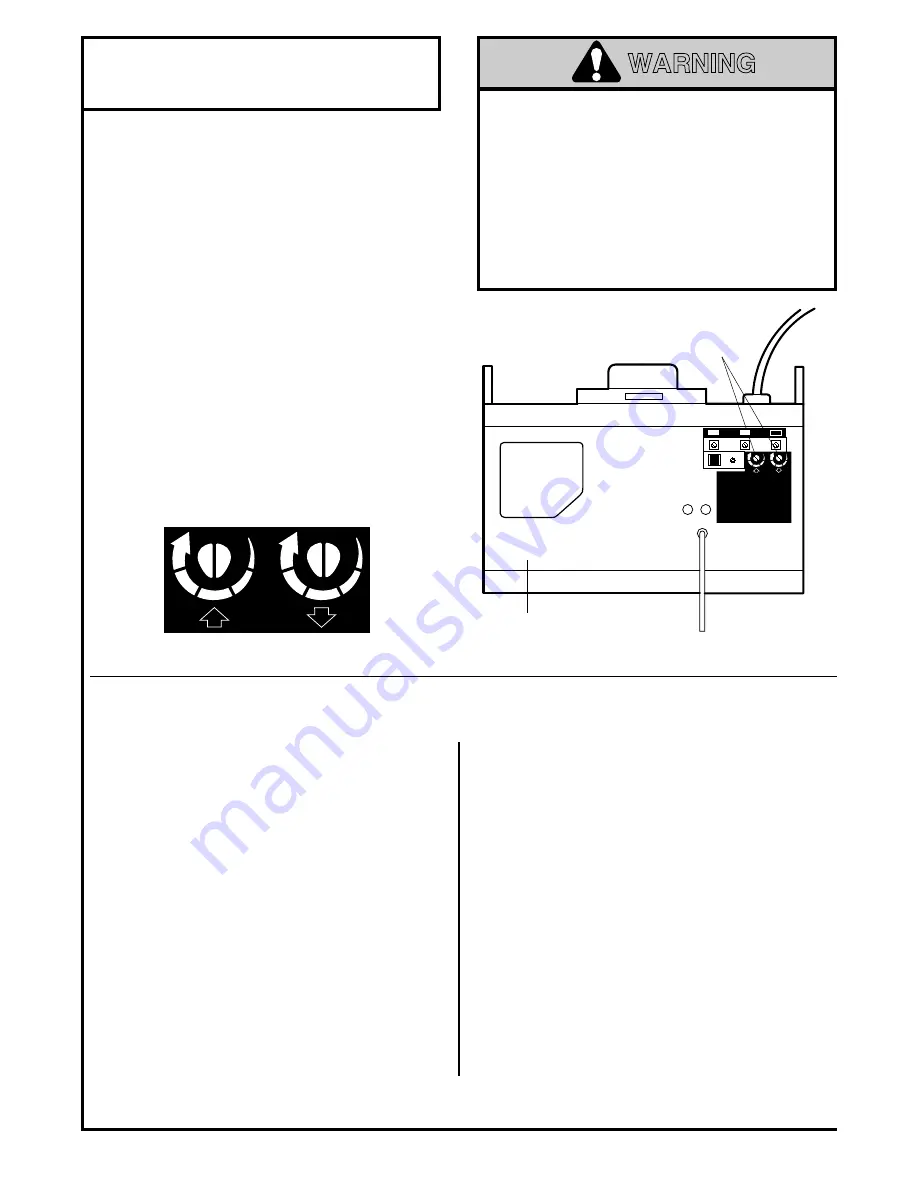

Force adjustment controls are located on the back

panel of the opener. Force adjustment settings

regulate the amount of power required to open and

close the door.

The door will

stop in the up direction if anything

interferes with its travel. The door will

reverse in the

down direction if anything interferes with its travel

(including binding or unbalanced doors).

If the forces are set too light, door travel may be

interrupted by

nuisance reversals in the down

direction and

stops in the up direction. Weather

conditions can affect the door movement, so

occasional adjustment may be needed.

The maximum force adjustment range is

260 degrees, about 3/4 of a complete turn. Do not

force controls beyond that point. Turn force

adjustment controls with a screwdriver.

The Chamberlain Group, Inc.

Step 2 Adjust Force - CGI

5/1/92 - 5/5/92 - 5/26/92

Force

Adjustment

Controls

Back Panel

of Opener

KG

KG

1

3

9

7

5

1

3

9

7

5

1

2

3

Adjustment Label

KG

KG

1

3

9

7

5

1

3

9

7

5

How and When to Adjust the Forces

Test the DOWN (close) force

Grasp the door bottom when the door is about

halfway through DOWN (close) travel. The door

should reverse.

Reversal halfway through down

travel does not guarantee reversal on a one-inch

obstruction. See page 26. If the door is hard to

hold or doesn't reverse, decrease the DOWN (close)

force by turning the control counterclockwise.

Make 10 degree turn adjustments until the door

reverses normally. After each adjustment, run the

opener through a complete cycle.

Test the UP (open) force

Grasp the door bottom when the door is about

halfway through UP (open) travel. The door should

stop. If the door is hard to hold or doesn't stop,

decrease UP (open) force by turning the control

counterclockwise.

Make 10 degree turn adjustments until the door

stops easily. After each adjustment, run the opener

through a complete travel cycle.

If the door doesn't open

at least 5 feet

Increase UP (Open) force by turning the control

clockwise. Make 10 degree turn adjustments until

door opens completely. Re-adjust the UP limit if

necessary. After each adjustment, run the opener

through a complete travel cycle.

If the door

reverses during the down (close) cycle

and the opener lights aren't flashing

Increase DOWN (close) force by turning the control

clockwise. Make 10 degree turn adjustments until the

door completes a close cycle. After each adjustment,

run the opener through a complete travel cycle. Do

not increase the force beyond the minimum

amount required to close the door.

25

The Chamberlain Group, Inc.

Step 2 Adjust Force - CGI

5/1/92 - 5/5/92 - 5/26/92

Force

Adjustment

Controls

Back Panel

of Opener

KG

KG

1

3

9

7

5

1

3

9

7

5

1

2

3

Adjustment Label

KG

KG

1

3

9

7

5

1

3

9

7

5

WARNING

CAUTION

WARNING