Installation Guide Linear Motors

ENG

Page 32 / 47

P01-48-HP EX protected

NTI AG / LinMot

4.7 Check before commissioning

Prior to commissioning, important components should be tested. See the table below.

When

What

Task

Prior to

commissioning

Electrical

connection

Tighten the plug thread.

(Torque 5 Nm)

Tightness

Check that external bearings are securely threaded onto

the stator with no gap.

(Torque 6 Nm)

Ease of movement

Align the motor for load attachment so that the slider can

move freely.

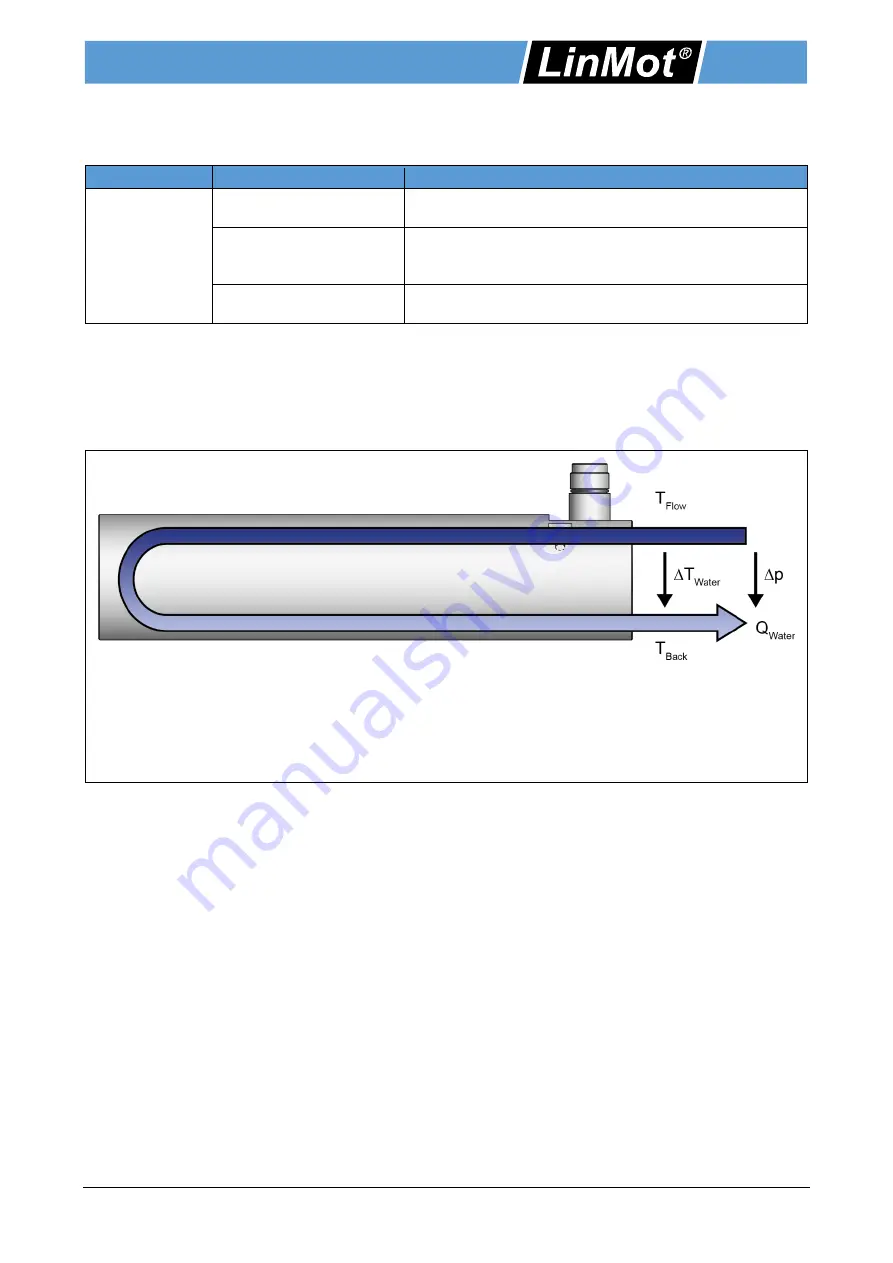

4.8 Design of water cooling

This paragraph relates to the ATEX linear motor versions with liquid cooling (motor identification numbers

with the suffix

–FC). The heat produced by the motor is dissipated by the liquid cooling. If the motor is

operated with a liquid-cooling, the continuous force value increases many times in comparison with the self-

cooling.

T_Flow:

Flow temperature

T_Back:

Return temperature

ΔT:

T_Back-T_Flow

T_Water:

( T_Back) / 2 (Mean coolant temperature)

Q_Water:

Flow

Δp:

Differential pressure

With the water cooling, the coolant is passed through the cooling circuit of the motor flange.

Starting from the adjusted mean coolant temperature T_Water all other parameters of the cooling circuit may

be dimensioned based on the diagrams referred to:

•

T_Water -> Pv_Max (Continuous power dissipation) -> Q_Water ->

Δp

The design is illustrated by an example in the following.

Summary of Contents for 0150-4370

Page 42: ...Installation Guide Linear Motors ENG Page 42 47 P01 48 HP EX protected NTI AG LinMot ...

Page 43: ...Installation Guide Linear Motors ENG NTI AG LinMot P01 48 HP EX protected Page 43 47 ...

Page 44: ...Installation Guide Linear Motors ENG Page 44 47 P01 48 HP EX protected NTI AG LinMot ...

Page 46: ...Installation Guide Linear Motors ENG Page 46 47 P01 48 HP EX protected NTI AG LinMot ...