Installation Guide Linear Rotary Motors

ENG

NTI AG / LinMot

PR02-70

Page 17 / 41

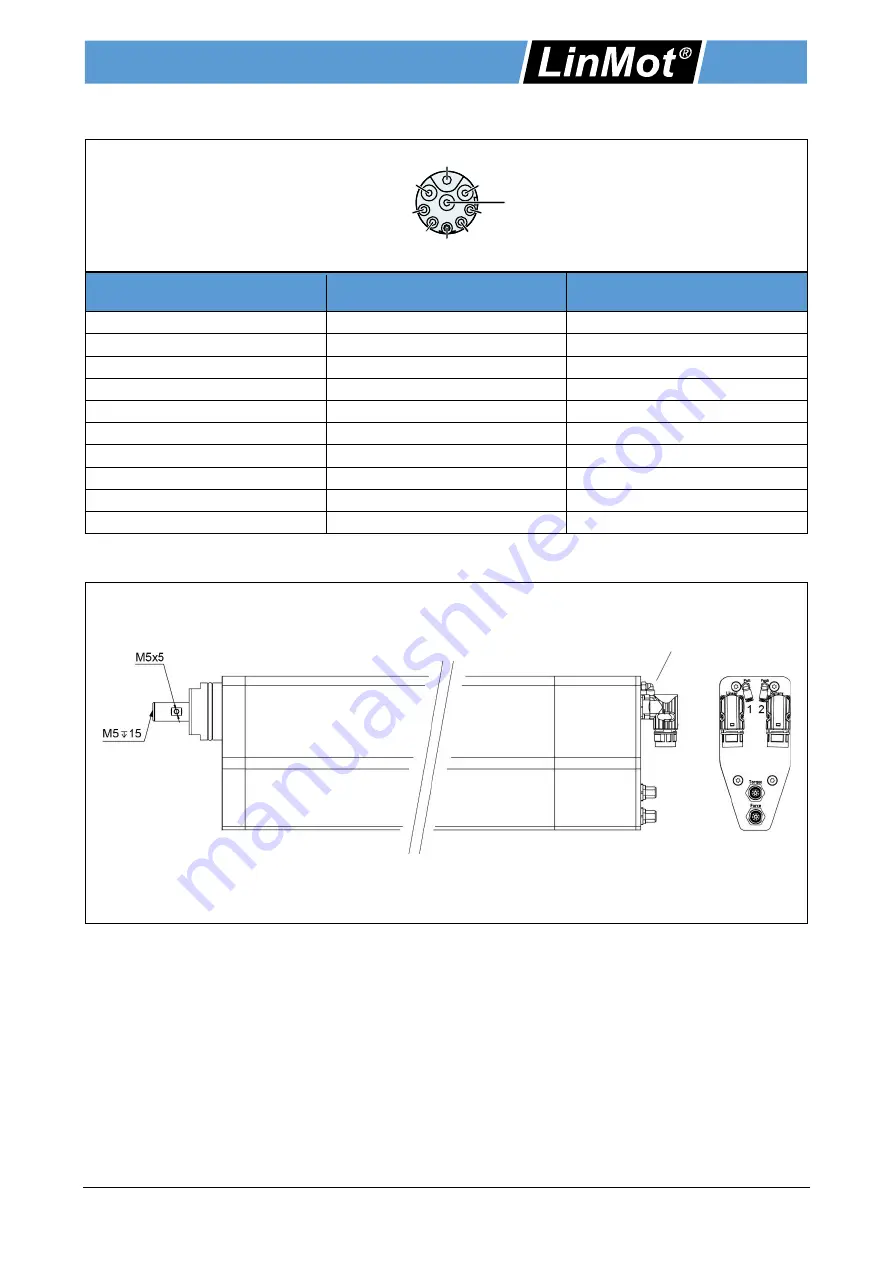

5.2 Connector Wiring Electric Pusher

View: Motor connector, plug side

Connector wiring

Electric Pusher

R-Connector

Wire colour

Motor cable

Ph 1+ / Ph A

1

red

Ph 1- / Ph B

2

pink

Ph 2+ / Ph C

3

blue

Ph 2- / (-)

4

grey

+5VDC

A

white

GND

B

Inner shield

Sin

C

yellow

Cos

D

green

Temp.

E

black

Shield

Housing

Outer shield

5.3 Connection of Air

Configuration of air connection

Pos. 1: Air connection with option (L01) / "Pull" with option Pn. Pusher

Pos. 2: "Push" with option Pn. Pusher

The PR02-70 is optionally equipped with a hollow shaft for air feed-through or for integration of a pneumatic

pusher. Depending on the option, there are several pneumatic push-in fittings (external hexagon M5) for a Ø

4 mm hose at the rear of the motor, above the electrical plug connections. Inside the motor, a Ø 4 mm air

hose is routed along the rotary shaft. This enables the user to realise pneumatic applications with an

operating pressure of max. 6 bar.

Depending on the order situation (option "hollow shaft" or option "pneumatic pusher"), 1 or 2 push-in

connections are pre-assembled. The user also has the option of mounting a pneumatic push-in fitting on the

front of the shaft. For this purpose, the user has an M5 (15 mm deep) in the axial direction and an M5 (5 mm

deep, recommended push-in fitting KAH04-M5 with a total length of 17 mm) in the radial direction. The

through hole in the rotary shaft is Ø 4 mm.

In the case of vacuum application, it is recommended to use a unit with sufficient power, as experience has

shown that all air coupling points generate small losses.

Push-in fitting

External hexagon M5

for a Ø 4 mm hose

2

4

1

A

B

C

D

E

3