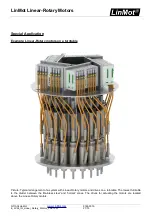

LinMot Linear-Rotary Motors

Notes on application of the PR01-84x80-SSC series

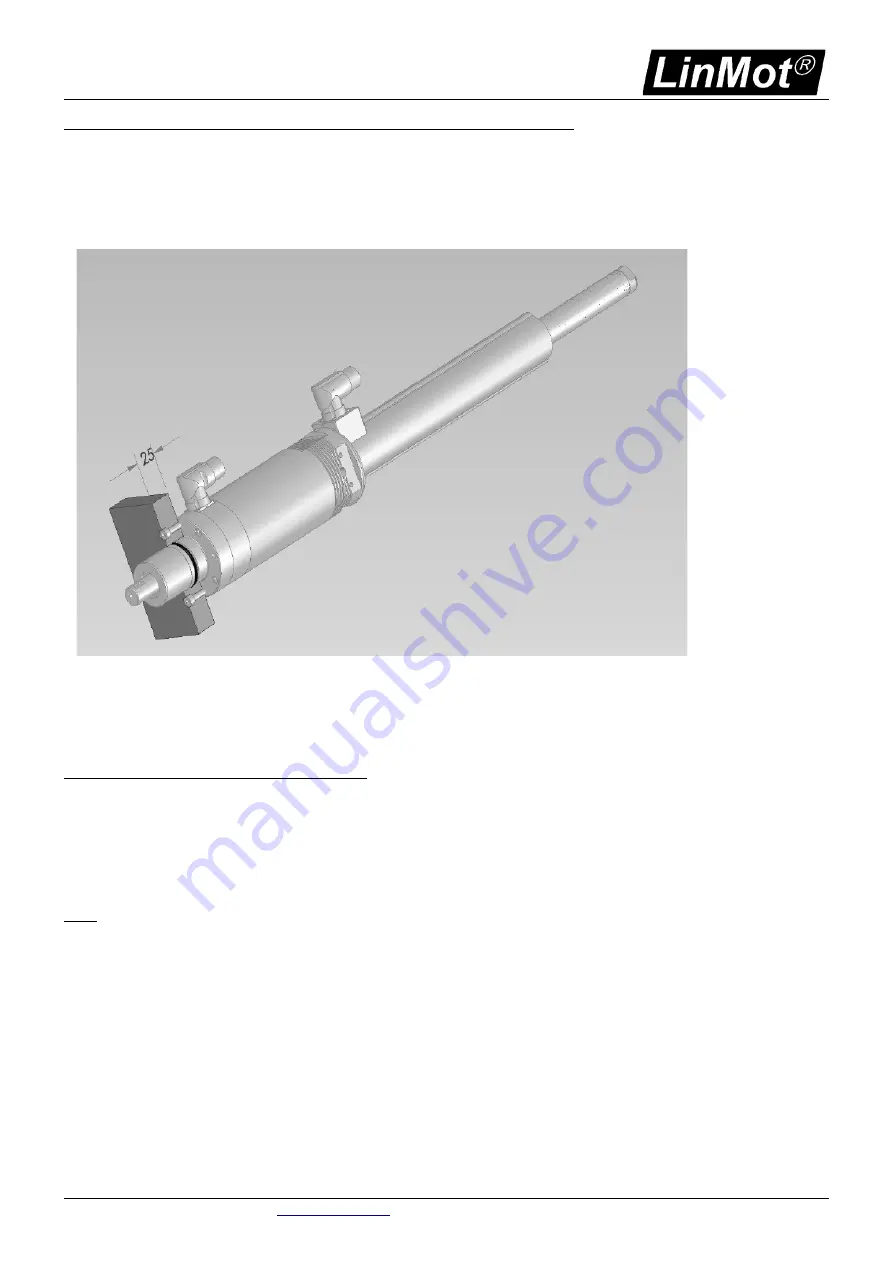

The design of the machine should consist of a 'normal' and a 'stainless steel' zone. The 'stainless steel zone' can

be cleaned accordingly during operation. The two zones are separated by a stainless steel plate. The flange of the

Linear-Rotary motor, also made of stainless steel, is inserted through this steel plate. The cylindrical front end of

the flange has a groove with an O-ring that acts as a seal between the 'normal' and the stainless steel zones.

Picture: O-ring for sealing between 'normal' and 'stainless steel' zone .

Notes on cleaning the SSC variants

The rotary axis should not be set in motion while the line is being cleaned. It should be either fully extended or fully

retracted. The chromium steel zone has IP65 class protection. The seals are made from FKM fluorelastomer and

85 AU 20991 polyester-urethane rubber.

Note

Linear-Rotary units with new or replaced seals will show an increased friction on both movements (linear and

rotation) during the first hours of operation.

NTI AG/ LinMot

0185-0015-

E_2V94_IG_Linear_Rotary_Motors_PR01.odt

26/79