LinMot Linear-Rotary Motors

Maintenance of

LinMot

®

Linear-Rotary Motors

LinMot Stators will be shipped with an initial lubrication. Maintenance will only be required if the motors run 'dry' or

there is a heavy pollution of the motors.

Under normal industrial conditions (5 day, 8h/day) one inspection every 3 months is adequate. Where conditions

differ, as with severe and permanent fouling, direct sunshine, operation out in the open, increased operating

temperature etc., the maintenance intervals must be shortened till empirical values for the particular application are

obtained.

Inspection

Inspections have to be executed according to the operating condition and the load of motors. Following points have to be

checked during inspection:

Is a film of lubricant on the slider?

Is the wiper (if existent) without visible wear?

Is the lubricant not adhesive?

Can the slider be moved easily?

If the motors are heavily polluted respectively if no film of lubricant is on the slider, then stators and sliders must be cleaned and

lubricated again.

Cleaning and lubrication

Disassembling and cleaning

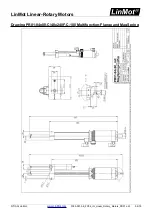

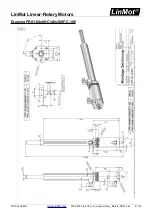

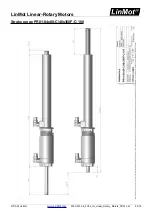

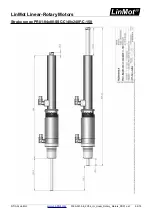

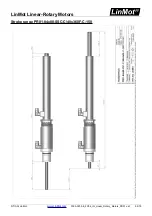

If existing, remove wiper (1) from the stator. Open fastening screws (2a, 2b and if existing 2c) between rotary motor

and linear motor. Pull the stator (2) rapidly back over the slider (5) to prevent sticking to the Stator (3). Don't

attempt to loosen the slider (5) from the rod (6). Attention: huge magnetic attraction of the slider! Clean slider (5),

stator (3) and grooves (6) with cleaning agent LU06.

NTI AG/ LinMot

0185-0015-E_2V94_IG_Linear_Rotary_Motors_PR01.odt

73/79