Shenzhen Linshang Technology Co., Ltd.

3/12/2022 Page 3 of 8

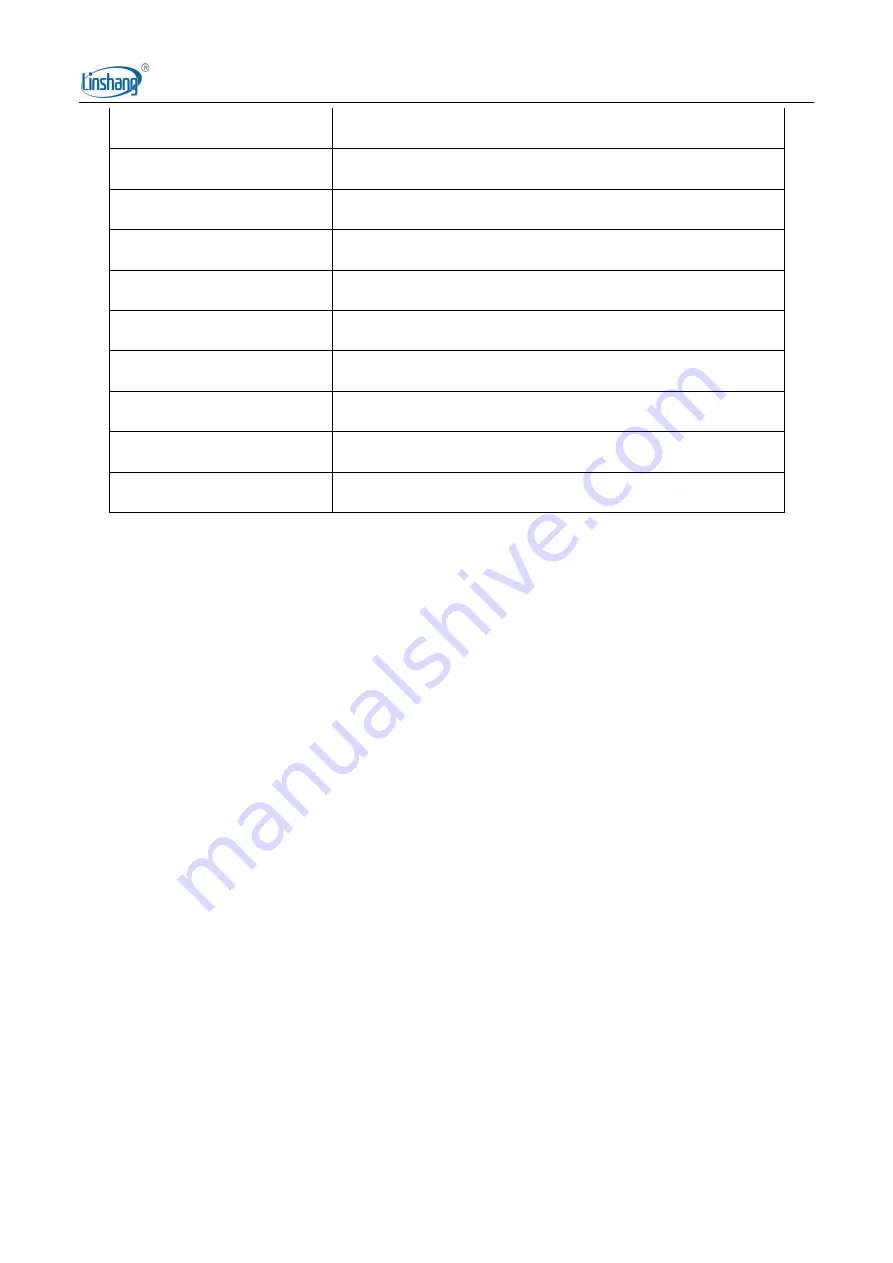

Measuring interval

0.5s

Minimum measuring area

Ø = 25mm

Minimum curvature

Convex:5mm / Concave:25mm

Minimum substrate thickness

Fe:0.2mm / NFe:0.05mm

Display

Front: 128×48 dot matrix LCD, top: 128×64 dot matrix OLED

Power supply

2 pcs of 1.5V AAA alkaline battery

Operation temperature range

-40

℃

-50

℃

Storage temperature range

-50

℃

-60

℃

Gauge size

100*60*24 mm

Weight(with battery)

80g

III. Features

1. No calibration, just zero adjustment.

2. Simple operation by pressing one button.

3. Fast measurement, 0.5s measuring interval.

4. Dual display design, display the measured value simultaneously. It is convenient to view the test data

in real time when measuring at different angles.

5. Using LCD and OLED as display devices simultaneously, LCD ensures that the test results are clearly

visible under strong light and OLED ensures normal display in a low temperature environment of -

40°C.

6. The device can identify the ferrous putty as well as the galvanized iron substrate.

7. Wear-proof ruby probe tip for long-term use.

8. Dual-use probe for both iron and aluminum. The gauge can automatically identify the substrate and

switch measurement mode rapidly.

9. "Fe", "NFe", "Fe/NFe" three measurement modes can be set.

10. The gauge can measure the non-magnetic coating thickness on metal substrates and non-conductive

coating thickness on non-magnetic substrates.

11. Use advanced digital probe technology, these sensors are unsusceptible to interference and provide

an excellent measuring accuracy. Even temperature change will not affect measurement and data

remain stable to ensure a very good reproducibility over the complete measuring range.