4

SMOKE

ON

OFF

SMOKE

OFF

ON

WHISTLE

ON

OFF

WHISTLE

ON

OFF

REVERSE

ON

OFF

REVERSE

ON

OFF

T

he electronic reverse unit inside your Lionel locomotive acts like the transmission in a car.

When you apply power to the track, the locomotive moves in the direction specified by the

reverse unit—or it sits in neutral, awaiting another power interruption. Power interruptions

are the signal that tells the reverse unit to sequence to the next operational state.

To interrupt power and sequence the locomotive’s reverse unit, press the direction control

button or briefly bring the throttle lever all the way back to the OFF position. The reverse unit

alternates between three states: forward, neutral, and reverse.

Also, the locomotive can be “locked” into a certain mode of operation by throwing the

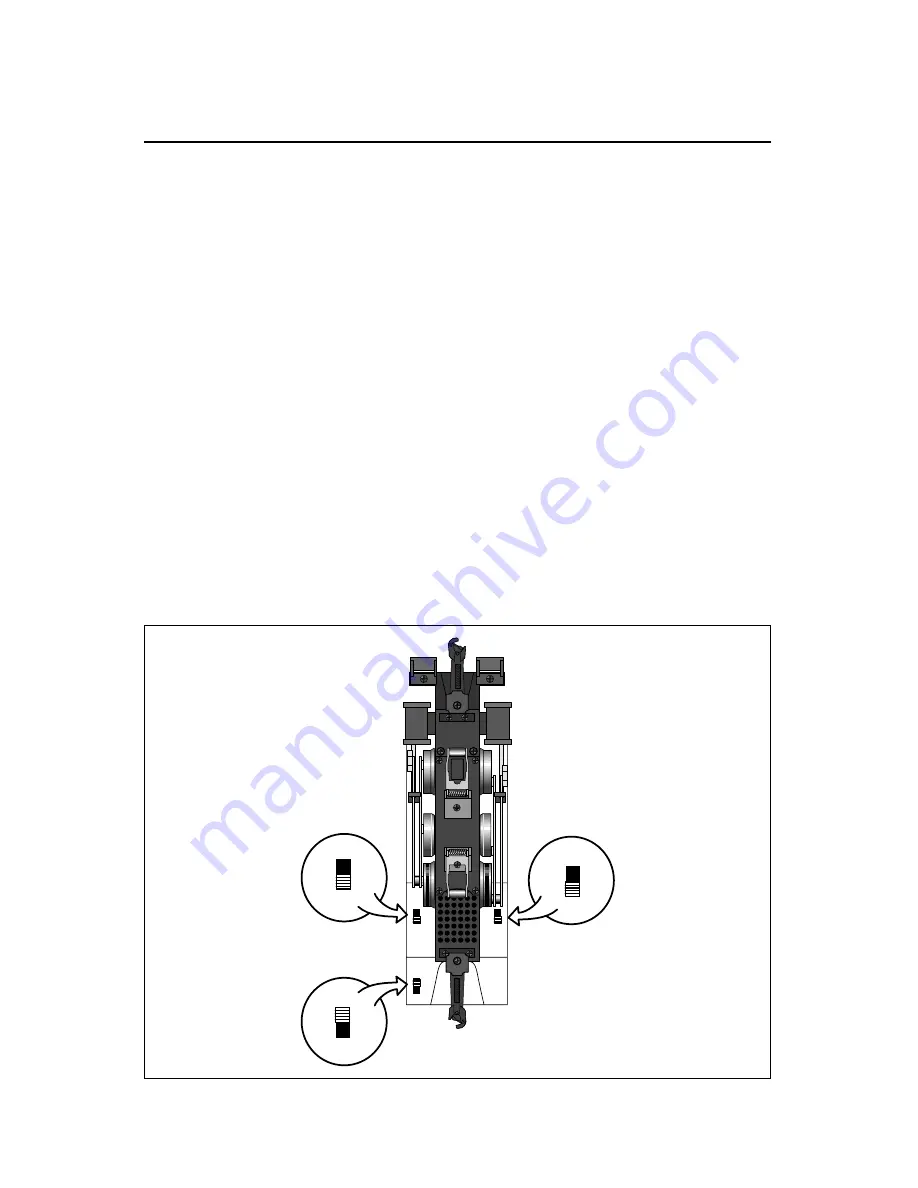

reverse unit switch located on the underside of the frame. See Figure 1. To lock your

locomotive into a specific operational state, sequence the locomotive into the desired state and

reduce track power without completely powering down the locomotive, then throw the switch

to the OFF position. The DIRECTION button or other track power interruptions will then have

no affect on the direction of the locomotive. If you would like to resume forward-neutral-

reverse operation, simply throw the reverse unit switch back to the ON position.

Additionally, this reverse unit has a “power-up reset” feature. If the locomotive sits without

power for an extended period of time, the reverse unit will automatically reset and start in the

forward direction when the transformer is turned on or “powered up,” regardless of the reverse

unit switch position. If the switch is in the OFF position, the locomotive will start in the forward

direction and be “locked” there.

Locking your locomotive into a single operational state

Transformer operations

Figure 1. Switch location

Smoke unit switch

Reverse unit switch

Whistle switch

FRONT

REAR