Rev: 11.23.22

Page 10

CCD-0004307

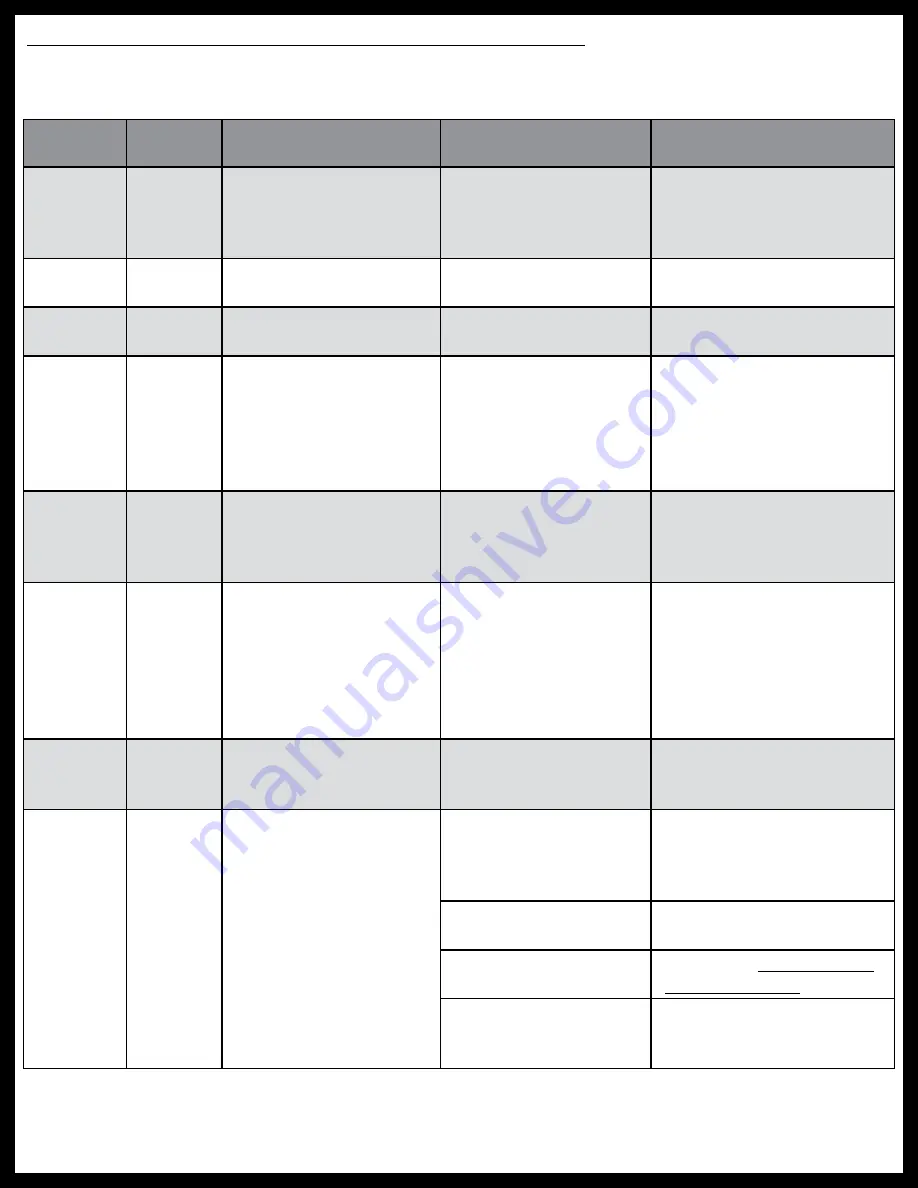

Diagnostic Troubleshooting Codes: Indicator Light Descriptions

The following chart contains troubleshooting tips if system is not operating properly, but the touch pad is

supplying a trouble code.

Flashing

Lights

Fault

Code

Description of

Operation

Probable Cause

Corrective Action

Low

Voltage

Low

Voltage

Low Voltage light ON,

solid or flashing. May/not

all operation

Batteries are low

Ignition ON, start coach.

Allow batteries to charge.

Engine must be running to

operate jacks

On/Off

and Wait

Trans.

Will not allow operation

Transmission is in gear

Place transmission in Park,

or Neutral for diesel coach

Parking

Brake

Parking

Brake

Will not allow operation

Parking brake NOT

engaged

Engage parking brake

Left,

Right,

Front,

Rear AND

Power

Gear logo

Excess

Slope

Lights flash constantly,

leveling is possible

1) Too steep/uneven

terrain

2) Control improperly

programmed

1) Move coach to level

ground

2) See TIP sheet 82-L0317 to

reprogram control

Jacks

Down

and Wait

Pressure

Loss

Will not allow operation

System has leak and

needs serviced

Take coach to authorized

service center for repair.

Note: ONLY hydraulic

system needs serviced.

On/Off,

Jacks

Down

and

Parking

Brake

Comm.

Error

Will not allow operation

Faulty wiring, poor

connection or faulty

component

Check connections. Cycle

ignition to reset. Replace

components individually in

following order:

1. Touch pad harness

2. Touch pad

3. Control box

All Lights

On,

Constant

Internal

Error

Will not allow operation

Internal error

New Control box needed.

Touch pad is good.

Left,

Right,

AND

Power

Gear logo

Timeout

Error

Leveling operation

aborted. Internal timers

could have tripped. Built-

in timers protect hyd.

pump and/or damage to

coach. Common errors:

- jacks took too long to

retract

- jacks took too long to

auto level

Batteries are low

Ignition ON, start coach.

Allow batteries to charge.

Engine must be running to

operate jacks

Too steep/uneven

terrain

Move coach to level ground

Thick hydraulic fluid

due to low temperature

See section: Hydraulic Fluid

Recommendation

Air in system

Check for coils in hose.

Remove coil if present and

extend all jacks