Rev: 11.23.22

Page 6

CCD-0004307

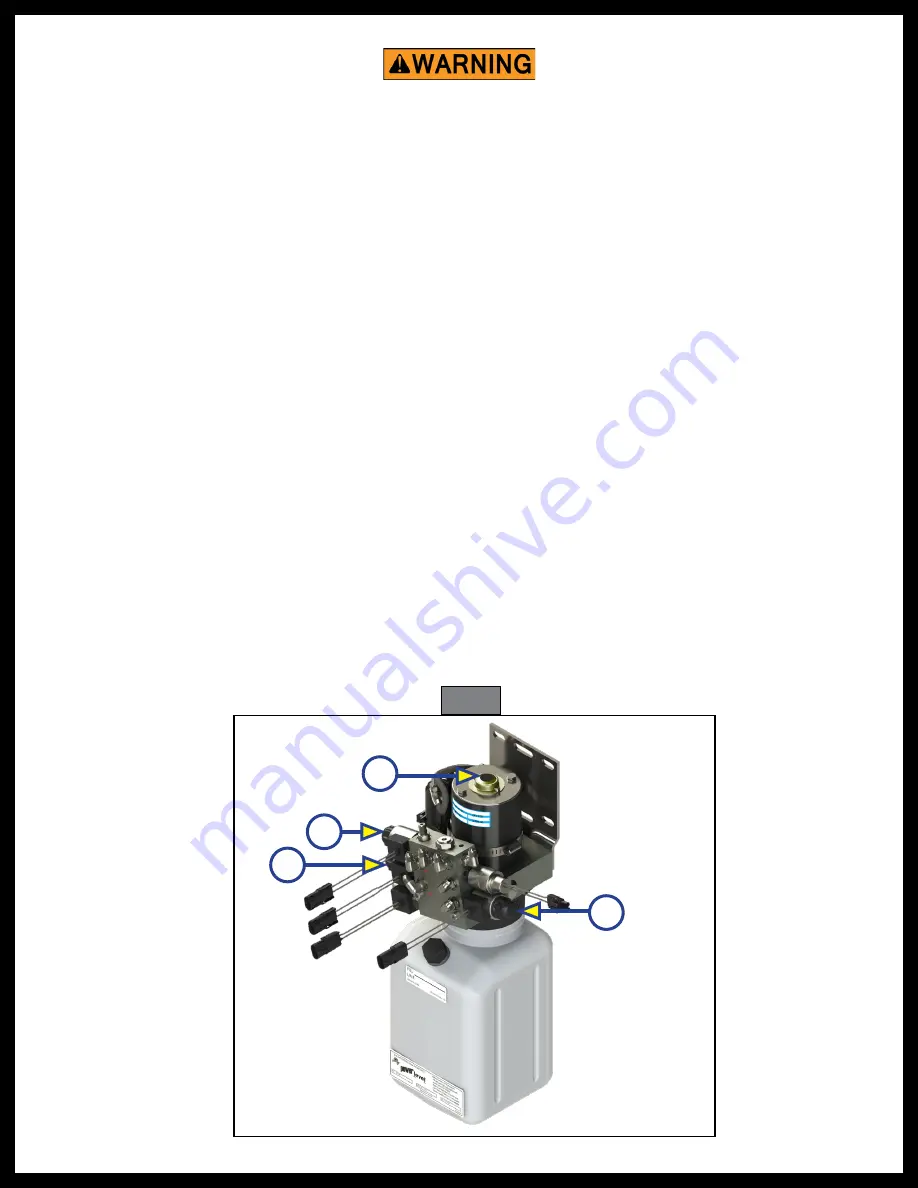

Manual Override

In case of a loss of power at the pump assembly, the manual override valves (MOV’s) can be used to retract

the leveling jacks. Not all Power Gear leveling system pumps have manual override valves. Power units for

double acting systems that have manual override valves have flexible rubber caps on the valves and a hex

override nut under the plastic cap on the electric motor.

To use the MOV’s:

1.

Remove the PLASTIC CAP (Fig. 2A) from the end of the electric motor. You should now see a 7/16”

override nut on the end of the electric motor shaft.

2.

After verifying all personnel and tools are clear of the press the rubber cap on the valve for the FRONT

LEG VALVE (Fig. 2B) The front end of the coach will start to descend. Allow coach to descend 2 inches.

3.

Push and hold rubber cap on the ROADSIDE REAR VALVE. (Fig. 2D) Allow coach to descend 2 inches.

4.

Push and hold rubber cap on the CURBSIDE REAR VALVE (Fig. 2C) Allow coach to descend 2 inches.

5.

Repeat procedures 2-4 until the weight of the coach is transferred off the jacks and onto the

suspension and tires.

6.

This procedure will retract the front legs. Using a 7/16” socket attached to a drill, spin the override nut

clockwise while holding the button on the FRONT LEG VALVE (Fig. 2B). Stop when the legs are fully

retracted.

7.

This procedure will retract the roadside rear leg. After the front legs are retracted, press the button on

the ROADSIDE REAR VALVE (Fig. 2D) and spin the override nut clockwise. Stop when the leg is fully

retracted.

8.

This procedure will retract the curbside rear leg. After the front legs are retracted, press the CURBSIDE

REAR VALVE (Fig. 2C) and spin the override nut clockwise. Stop when the leg is fully retracted.

9.

Replace the PLASTIC CAP (Fig. 2A) on the electric motor.

Fig. 2

Care must be taken during the manual retraction of jacks to prevent bodily injury or death. The next

steps will allow fluid to transfer from the legs to the reservoir. This procedure will allow the coach to

descend. Keep all personnel and equipment clear of the coach. Make sure no one is under the coach

prior to this procedure. Do not have any body parts or equipment positioned such that the coach

A

B

C

D