25

GAMMA SERIES ENGINES OpERATORS' hANdbOOk

4. Open the tap or remove the drain plug at the bottom of the radiator in order to

drain the radiator. If the radiator does not have a tap or a plug, disconnect the

hose at the bottom of the radiator.

5. If necessary, flush the system with clean water.

6. Fit the drain plugs and the filler cap. Close the radiator tap or connect the

radiator hose.

5.3 ChECkING ThE dRIvE bElTS

Always renew a belt if it is worn or damaged.

If twin belts are fitted, they must be renewed together.

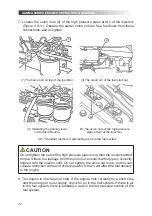

To ensure maximum belt life, it is recommended that a belt tensioner gauge is used

to check the belt tension. Fit the gauge

(Figure 5.3)

at the centre of the longest free

length and check the tension. If a Burroughs gauge is used, the correct tension

is 355N (80 Ibf or 36 kgf). If the tension is below 220N (50 Ibf or 22 kgf) adj st to

355N as indicated below.

21

GAMMA SERIES ENGINES OPERATORS' HANDBOOK

5.3 CHECKING THE DRIVE

BELTS

Always renew a belt if it is worn or

damaged.

If twin belts are fitted, they must be

renewed together.

To ensure maximum belt life, it is

recommended that a belt tensioner

gauge is used to check the belt

tension. Fit the gauge (

Figure 5.3

) at

the centre of the longest free length

and check the tension. If a Burroughs

gauge is used, the correct tension is

355N (80 Ibf or 36 kgf). If the tension

is below 220N (50 Ibf or 22 kgf) adj st

to 355N as indicated below.

5.3 Using the belt tensioner gauge

If a gauge is not available, press down

the belt with a thumb at the centre of

the longest free length and check the

deflection (

Figure 5.3

). With moderate

thumb pressure, 45N (10 Ibf or 4.5 kgf),

the correct deflection is 10mm 3/8in).

If twin belts are fitted, check and if

necessary adjust the tension on the

tighter belt.

5.3.1 Adjusting the Belt Tension

Refer to

Figure 5.3.1

below.

1.Loosen the pivot fasteners of the

alternator (1) and also the adjustment

link fasteners (2).

5.3.1 Checking drive belt tension without

a gauge. (1) Pivot fasteners of alternator;

(2) Adjustment link fasteners.

2.Change the position of the alternator

to give the correct tension, tighten the

pivot fasteners of the alternator and the

adjustment link fasteners.

3.Check the belt tension again to

ensure that it is st ill correct. If a new

belt is fitted, the belt tension must be

checked again.

5.4 CLEANING THE FUEL LIFT

PUMP

Refer to

Figure 5.4.

1.Remove t he fuel lift pump and place

into clean fuel.

5.4 The fuel lift pump

5.3 Using the belt tensioner gauge

If a gauge is not available, press down the belt with a thumb at the centre of the

longest free length and check the deflection

(Figure 5.3)

. With moderate thumb

pressure, 45N (10 Ibf or 4.5 kgf), the correct deflection is 10 mm 3/8 in).

If twin belts are fitted, check and if necessary adjust the tension on the tighter belt.

5.3.1 Adjusting the belt Tension

Refer to

Figure 5.3.1

below.

1. Loosen the pivot fasteners of the alternator (1) and also the adjustment link

fasteners (2).

Summary of Contents for GW3

Page 59: ...59 ...