TS, TR, TX engines workshop manual

25

Cleaning an Injector

A thoroughly cleaned container holding a supply • of clean, fresh

fuel oil should be available for washing dismantled parts.

The components of each individual injector • should be kept

together at all times.

Never use paraffin or woven cloths; it is • permissible to use

non-fluffing paper during the cleaning process.

Components should be assembled wet.•

Setting the Injector

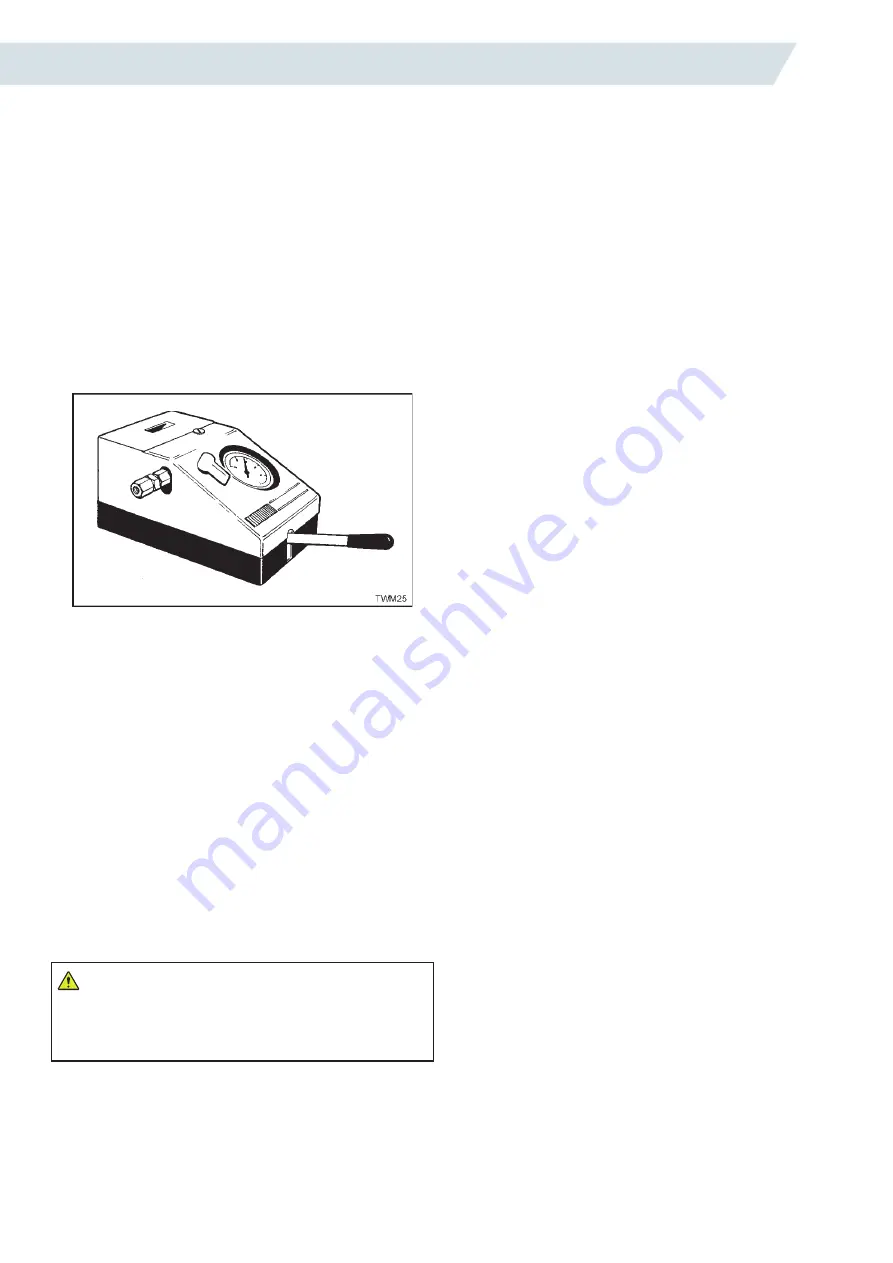

To ascertain if the injector is in good condition, it is removed

from the engine and connected to a fuel injector test rig, similar

to the one shown.

T SERIES ENGINES WORKSHOP MANUAL

27

6.Fit the slide hammer to the adapter and remove

the injector.

WARNING

Care must be taken to ensure that any part of

the hand is not likely to become trapped between

the two parts of the slide hammer while it is

being used.

Cleaning an Injector

A thoroughly cleaned container holding a supply

•

of clean, fresh fuel oil should be available for

washing dismantled parts.

The components of each individual injector

•

should be kept together at all times.

Never use paraffin or woven cloths; it is

•

permissible to use non-fluffing paper during the

cleaning process.

Components should be assembled wet.

•

Setting the Injector

To ascertain if the injector is in good condition, it is

removed from the engine and connected to a fuel

injector test rig, similar to the one shown.

Figure 2.26.3 Typical Injector Test Rig

If a rig is not available it becomes necessary to

replace the complete injector by a new or serviced

one which has a clean nozzle and has been

correctly set.

All sprays should have the same appearance and

the same length of penetration in the air. If one

spray is shorter or weaker than the others this

means that the corresponding hole is partially

blocked and best results will not be obtained. If one

hole is totally blocked or the nozzle dribbles it must

be replaced.

When a new nozzle is fitted the injector must be

reset on a test rig. After testing and resetting the

injector top plug must be torque loaded to 27.1 Nm

(20.0lbf ft).

Note:

Injector setting pressures can be found

in 'Technical Data" in the relevant engine

section.

WARNING

Under no circumstances allow unprotected skin

to come into contact with the spray as the fuel

may enter the blood stream with fatal results.

Injector Back Pressure

The leak-off rate is 6-27 seconds between 172-

142bars (170-140atmos) on an injector tester using

Calibration C fluid, at a temperature of 15.5°C

(60°F).

Replacing an Injector

If the injector sealing washer has been used more

than once it will become compressed and may

adversely affect combustion. Care should be taken

to ensure two washers are not fitted.

1.Examine the oil seal ring for damage or cuts,

replace if necessary.

2.Ensure the injector sealing washer has been

removed and the seating in the cylinder head is

clean and smooth.

3.Lightly smear a very small amount of high melting

point grease to one side of a new injector sealing

washer and place it over the injector nozzle,

greased side first.

4.Replace the leak-off pipe to the injector.

5.Fit the injector into the cylinder head.

TS/TR Engines:

6.Replace the clamp and leave the Alien screw

finger tight.

7.Replace the fuel pump to injector pipe - do not

tighten.

8.Replace the leak-off pipe into the fuel tank.

9.Torque the clamp screw to 21.0Nm(15.5lbf ft).

10.Torque all fuel pipe nuts to 28.5Nm (21.0lbf

ft) and the leak-off pipe swivel union to 4.0Nm

(3.0lbf ft).

11.Replace the cylinder head covers.

12.After the initial run following an injector

replacement re-torque the injector clamp screw.

TX Engines:

13.Replace the clamp and leave the nuts finger

tight.

14.Replace the fuel pump to injector pipe - do not

tighten.

15.Push the leak-off pipe onto the injector.

16.Torque the clamp screw to 8.0Nm (6.0Ibf ft).

17.Torque all fuel pipe nuts to 28.5Nm (21.0lbf ft).

18.Replace the leak-off pipe into the fuel tank.

Figure 2.26.3 Typical Injector Test Rig

If a rig is not available it becomes necessary to replace the

complete injector by a new or serviced one which has a clean

nozzle and has been correctly set.

All sprays should have the same appearance and the same

length of penetration in the air. If one spray is shorter or

weaker than the others this means that the corresponding

hole is partially blocked and best results will not be obtained.

If one hole is totally blocked or the nozzle dribbles it must be

replaced.

When a new nozzle is fitted the injector must be reset on a test

rig. After testing and resetting the injector top plug must be

torque loaded to 27.1 Nm (20.0lbf ft).

Note:

Injector setting pressures can be found in 'Technical Data" in the relevant engine

section.

WARNING

Under no circumstances allow unprotected skin to come

into contact with the spray as the fuel may enter the

blood stream with fatal results.

Injector Back Pressure

The leak-off rate is 6-27 seconds between 172-142bars (170-

140atmos) on an injector tester using Calibration C fluid, at a

temperature of 15.5°C (60°F).

Replacing an Injector

If the injector sealing washer has been used more than

once it will become compressed and may adversely affect

combustion. Care should be taken to ensure two washers

are not fitted.

1. Examine the oil seal ring for damage or cuts, replace if

necessary.

2. Ensure the injector sealing washer has been removed and the

seating in the cylinder head is clean and smooth.

3. Lightly smear a very small amount of high melting point

grease to one side of a new injector sealing washer and place

it over the injector nozzle, greased side first.

4. Replace the leak-off pipe to the injector.

5. Fit the injector into the cylinder head.

TS/TR Engines

6. Replace the clamp and leave the Alien screw finger tight.

7. Replace the fuel pump to injector pipe - do not tighten.

8. Replace the leak-off pipe into the fuel tank.

9. Torque the clamp screw to 21.0Nm(15.5lbf ft).

10. Torque all fuel pipe nuts to 28.5Nm (21.0lbf ft) and the leak-

off pipe swivel union to 4.0Nm (3.0lbf ft).

11. Replace the cylinder head covers.

12. After the initial run following an injector replacement re-

torque the injector clamp screw.

TX Engines

13. Replace the clamp and leave the nuts finger tight.

14. Replace the fuel pump to injector pipe - do not tighten.

15. Push the leak-off pipe onto the injector.

16. Torque the clamp screw to 8.0Nm (6.0Ibf ft).

17. Torque all fuel pipe nuts to 28.5Nm (21.0lbf ft).

18. Replace the leak-off pipe into the fuel tank.

2.27 The Fuel Pump

The individual fuel pumps are located at the side of the engine

between the push rods and are secured to the crankcase by two

bolts. Early TS engines were fitted with a long headed bolt fitted

to the inside hole in the pump mounting flange.

Removing the Fuel Pumps

1. Drain the fuel tank or isolate the fuel supply.

2. Disconnect the fuel feed pipes at the pumps.

3. Remove the fuel pipes from the pumps to injectors taking care

to hold the fuel pump delivery valve holder with a spanner

to prevent it turning.

4. Remove the fuel pump inspection doors.

5. Release the spring tension of the speeder spring by

unscrewing the speed adjusting screws on the side of the

crankcase.

6. Using long nose pliers disconnect the speeder spring from

its spigot.

It may be necessary to turn the spigot until the hole axis is

parallel to the camshaft before removing the spring.

7. Disconnect the governor and pump interconnecting linkage

at the pumps.

Summary of Contents for TS/TR1

Page 1: ...P027 08270 edition 8 April 2021 TS TR TX Engines Workshop Manual T SERIES ...

Page 80: ...TS TR TX engines workshop manual 80 T SERIES ENGINES WORKSHOP MANUAL 90 ct ical Wiring i g ...

Page 85: ...TS TR TX engines workshop manual 85 T SERIES ENGINES WORKSHOP MANUAL 95 ...