page 4

5. Fan Assembly.

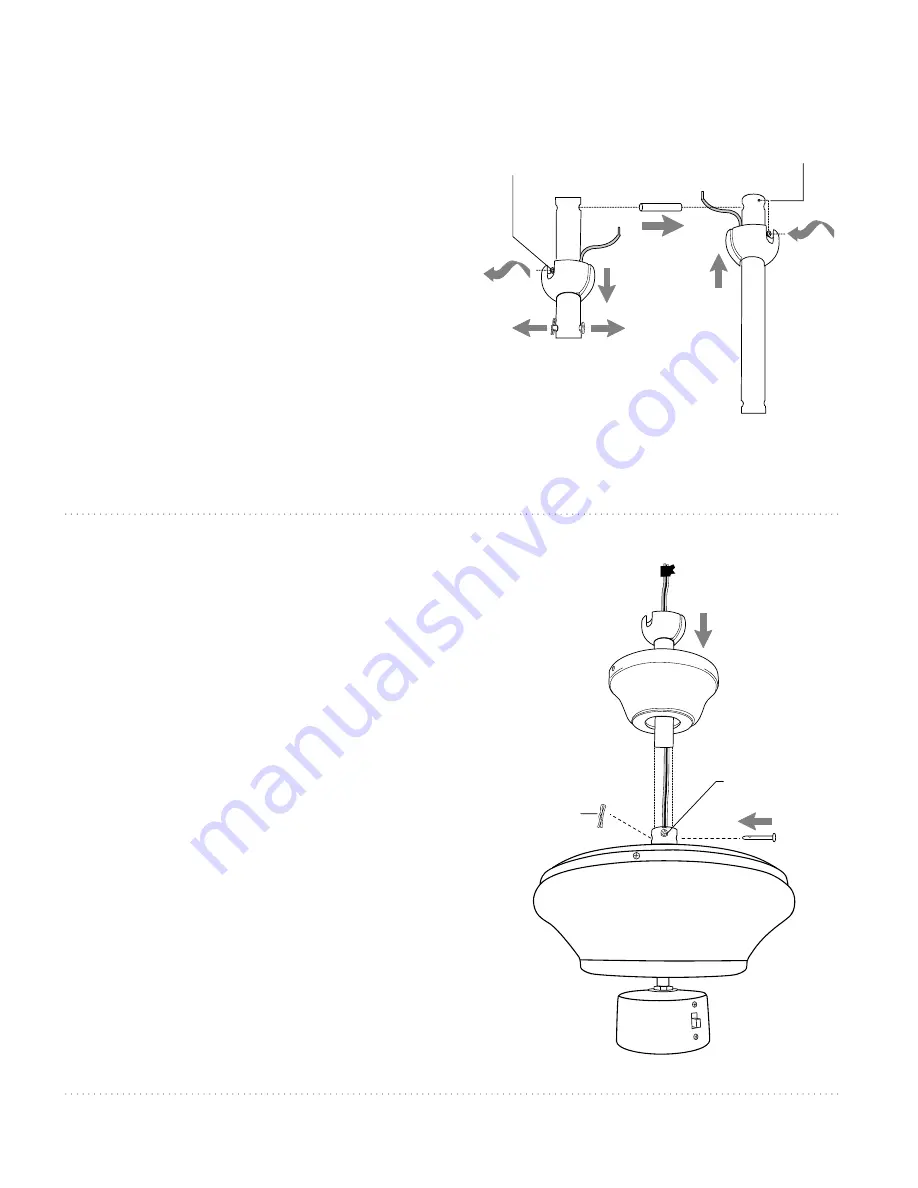

If you wish to extend the hanging length of your

fan, you must remove the hanging ball from the

downrod provided to use with an extended

downrod (sold separately). [

If you wish to use the

downrod provided, please proceed to instructions

following the dotted line below.

]

To remove hanging ball, loosen set screw on

hanging ball and remove the pin and clip. Lower

hanging ball and remove stop pin. Slide hanging

ball off the original downrod, A, and slide it

down the longer downrod, B (the top of the

downrod should be noted as having a set screw

hole; use this hole when setting the set screw).

Insert stop pin into top of extended downrod

and raise hanging ball. Be sure stop pin aligns

with slots on the inside of the hanging ball.

Tighten set screw securely.

Tip

: To prepare for threading electrical wires

through downrod, apply a small piece of

electrical tape to the ends of the electrical

wires--this will keep the wires together when

threading them through the downrod.

Loosen yoke set screws and nut at top of motor

housing. Remove pin and clip from downrod (if

you have not already done so). Slide downrod

through canopy.

Thread electrical wires through downrod and pull

extra wire slack from the upper end of the

downrod.

Place downrod into the motor housing yoke and

re-insert pin and clip that were previously

removed. Tighten yoke set screws and nut

securely. Lower canopy to motor housing.

["Fan Assembly" continued on next page.]

NOTE

: The important safety precautions and

instructions appearing in the manual are not meant to

cover all possible conditions and situations that may

occur. It must be understood that common sense and

caution are necessary factors in the installation and

operation of this fan.

set screw hole

set screw

hanging ball

stop pin

pin

clip

A

B

yoke set screw

downrod

electrical wiring

clip

pin

canopy

motor

housing