1. Reduce Belt Tension by loosening nuts on belt adjustment plate. (A)

2. Remove two nuts & bolts from pillow block bearing under the engine(B) and

remove spacer(C).

3. Slip the new belt over and under pillow block to the belt pulleys. Note: If

one belt needs replaced, all three belts need to be replaced at the same time

to assure maximum performance.

4. When belts are in place, replace spacer (C) and re-tighten belt adjustment

nuts until there is little slack in the belts (D).

5. If the digger blade slips when trenching, add more tension to the belts.

However, over tensioning will cause premature belt and/or bearing failure.

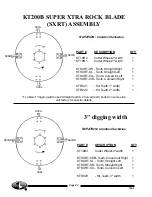

A

C

D

B

BELT REPLACEMENT INSTRUCTIONS

Summary of Contents for Kwik-Trench KT200B

Page 11: ...PARTS INFORMATION NOTES ...