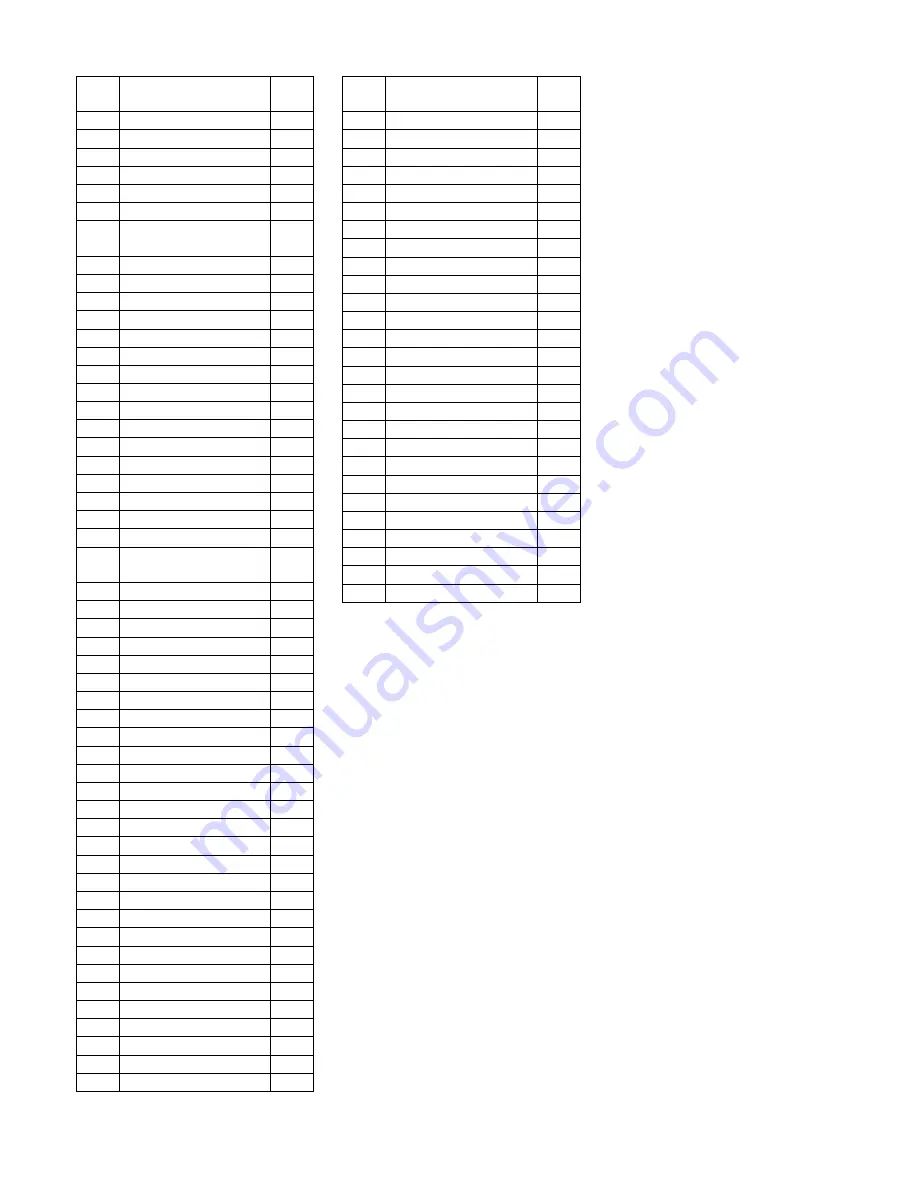

46

Dwg

PN

Description

LMS

PN

325 Nut, M8

5182

326 Handle

1347

327 Screw, M8×55

1565

328 Handwheel (7500)

4414

328 Handwheel (7550)

4165

329 Inner gear, 30T

5301

330

Gear protection

sleeve

5303

332 Washer

5597

333 Washer

5598

334 Protection cover

5236

335 Set screw, M6×5

2153

337 Oil cup

5269

338 Bolt (7500)

2145

338 Bolt (7550)

4184

339 Set screw, M4×10

5818

340 Scale ring sleeve

5293

341 Scale ring

5287

342 Worm shaft

5232

343 Key

5233

344 Set screw, M5×20

5819

345 Pin, 3×16 tapered

5323

347 Nut, M3

5939

350 Power cord

3380

401

Quick change tool

post set, 0XA

3112

402 Compound rest top

4914

403 Screw, M3×8

4167

404 Bracket

4168

405 Retainer

4169

406 Mount

4170

407 Screw, M4×25

5828

408 Feed screw

4171

409 Key, 2×6 mm

4172

410 Readout

5673

411 Screw, M3×25

1496

412 Key, 3×8 mm

1357

413 Bushing

4173

414 Set screw, M3×4

4174

415 Shaft

4175

416 Handwheel

4176

421 Handwheel

4176

422 Retainer

4177

424 Screw, M3×8

4166

425 Screw, M3×14

4178

426 Feed screw

4179

427 Spacer

6138

428 Retainer

6139

429 Bearing, 12×22×5

5720

430 Screw, M4×6

6141

431 Washer, M4

1583

432 Set screw, M5×6

6143

433 Screw, M3×20

5825

434 Spacer

6144

Dwg

PN

Description

LMS

PN

435 Scale, 1 m

5498

436 Screw, M4×10

1529

437 Bracket

6145

438 Washer

5799

439 Screw, M3×14

5823

442 Bracket back

6146

443 Screw, M3×6

1554

444 Stud

6147

445 Scale, 1 m

5498

446 Bracket front

6148

447 Screw, M2.9×9.5

2148

448 Spindle speed display 6149

449 Potentiometer

6151

450 Faceplate

6152

451 Protective plate

6124

452 Cover

6153

453 Knob

6154

456 Switch

5527

457 Cover

6156

458 Bluetooth sender

5784

459 USB port

6041

460 Cover

6159

461 Android tablet

5513

462 Stand

6160

463 Screw, M3×10

5822

464 Plug

6107

467 Cover

6163

Summary of Contents for HiTorque 7500

Page 40: ...40 Parts Diagram 7500 Model 7500 drawing 1...

Page 41: ...41 Model 7500 drawing 2...

Page 42: ...42 Parts Diagram 7550 Model 7550 drawing 1...

Page 43: ...43 Model 7550 drawing 2...

Page 47: ...47 Wiring Diagram...